Safe modified graphite and preparation method thereof

A safe and graphite technology, applied in graphite, electrical components, battery electrodes, etc., can solve the problem that graphite cannot meet the high and low temperature performance and excellent performance at the same time, and achieve the effect of good safety and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

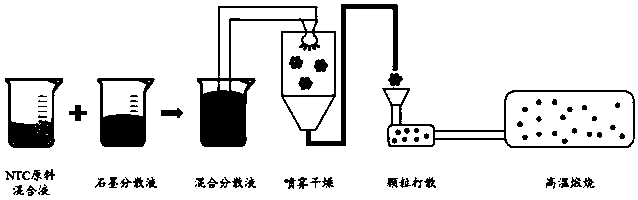

[0037] 1) Preparation of NTC-coated graphite precursor at room temperature:

[0038] a, take 5.1mmol Ni(CH 3 COO) 3 4H 2 O, 13.8mmol Mn(CH 3 COO) 2 4H 2 O, 2.2mmol Cu(CH 3 COO) 2 ·H 2 O and 0.7mmolZn(CH 3 COO) 2 4H 2 O was added to 50g deionized water, stirred for 1h, and configured as a mixed solution of NTC raw materials at normal temperature for subsequent use;

[0039] b. Add 95 g of artificial graphite with a particle size D50 of 20 μm into 500 g of absolute ethanol, ultrasonicate for 2 hours, and configure it into an absolute ethanol dispersion of graphite for later use;

[0040] c. Pour the mixed solution of NTC raw materials at normal temperature into the dispersion of graphite in anhydrous ethanol, and stir for 1 hour to obtain a mixed dispersion.

[0041] d. Use a spray dryer to coat and disperse the coated powder to obtain Ni 0.7 mn 1.9 Cu 0.3 Zn0.1 o 4 Precursor for coated graphite.

[0042] 2) Preparation of graphite negative electrode material: ...

Embodiment 2

[0046] 1) Preparation of NTC-coated graphite precursor at room temperature:

[0047] a, take 5.1mmol Ni(CH 3 COO) 3 4H 2 O, 13.8mmol Mn(CH 3 COO) 2 4H 2 O, 2.2mmol Cu(CH 3 COO) 2 ·H 2 O and 0.7Cr(CH 3 COO) 3 ·3H 2 O was added to 50g deionized water, stirred for 1h, and configured as a mixed solution of NTC raw materials at normal temperature for subsequent use;

[0048] b. Add 95 g of natural graphite with a particle size D50 of 25 μm into 500 g of absolute ethanol, ultrasonicate for 4 hours, and configure it into an absolute ethanol dispersion of graphite for later use;

[0049] c. Pour the mixed solution of NTC raw materials at normal temperature into the dispersion of graphite in absolute ethanol, and stir for 15 hours to obtain a mixed dispersion.

[0050] d. Use a spray dryer to coat and disperse the coated powder to obtain Ni 0.7 mn 1.9 Cu 0.3 Cr 0.1 o 4 Graphite-coated precursor.

[0051] 2) Preparation of graphite negative electrode material:

[0052...

Embodiment 3

[0055] 1) Preparation of NTC-coated graphite precursor at room temperature:

[0056] a, take 5.1mmol Ni(CH 3 COO) 3 4H 2 O, 13.8mmol Mn(CH 3 COO) 2 4H 2 O, 2.2mmol Cu(CH 3 COO) 2 ·H 2 O and 0.7Cr(CH 3 COO) 3 ·3H 2 O was added to 50g deionized water, stirred for 1h, and configured as a mixed solution of NTC raw materials at normal temperature for subsequent use;

[0057] b. Add 95 g of mesocarbon microspheres with a particle size D50 of 15 μm into 500 g of absolute ethanol, ultrasonicate for 0.5 h, and configure it into an absolute ethanol dispersion of graphite for later use;

[0058] c. Pour the mixed liquid of NTC raw materials at normal temperature into the dispersion liquid of graphite in anhydrous ethanol, and stir for 10 hours to obtain a mixed dispersion liquid.

[0059] d. Use a spray dryer to coat and disperse the coated powder to obtain Ni 0.7 mn 1.9 Cu 0.3 Cr 0.1 o 4 Precursor for coated graphite.

[0060] 2) Preparation of graphite negative electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com