A preparation method of digital inkjet printing water transfer printing film, water transfer printing film and water transfer printing method

A water transfer film, digital inkjet technology, applied in the copy/marking method, transfer ink from the original, chemical instruments and methods, etc., can solve the problem that the PVA film cannot be directly digitally inkjetted, etc., to prevent disorder. Diffusion, high speed, the effect of shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

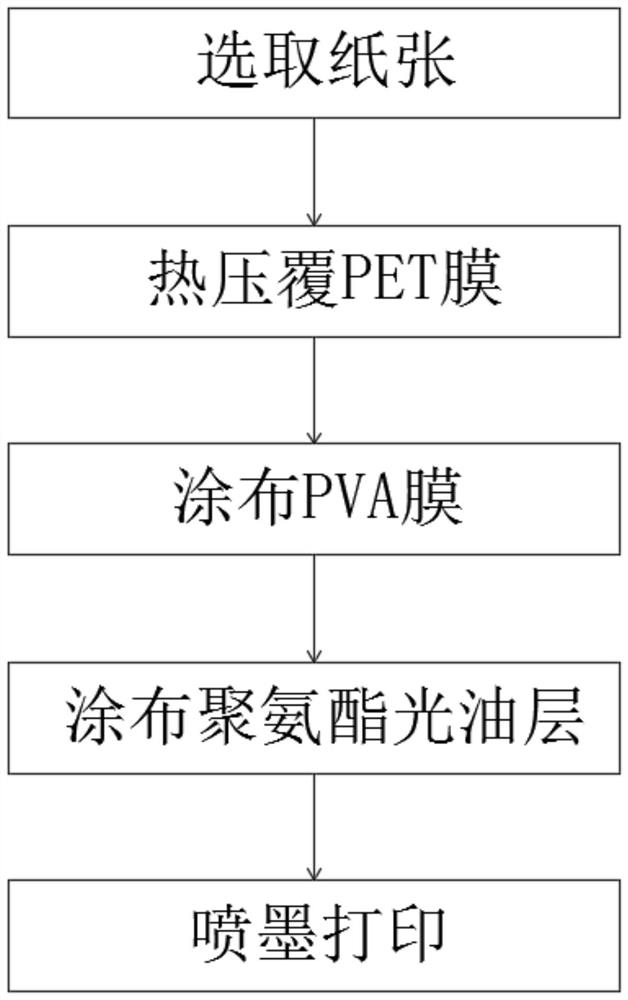

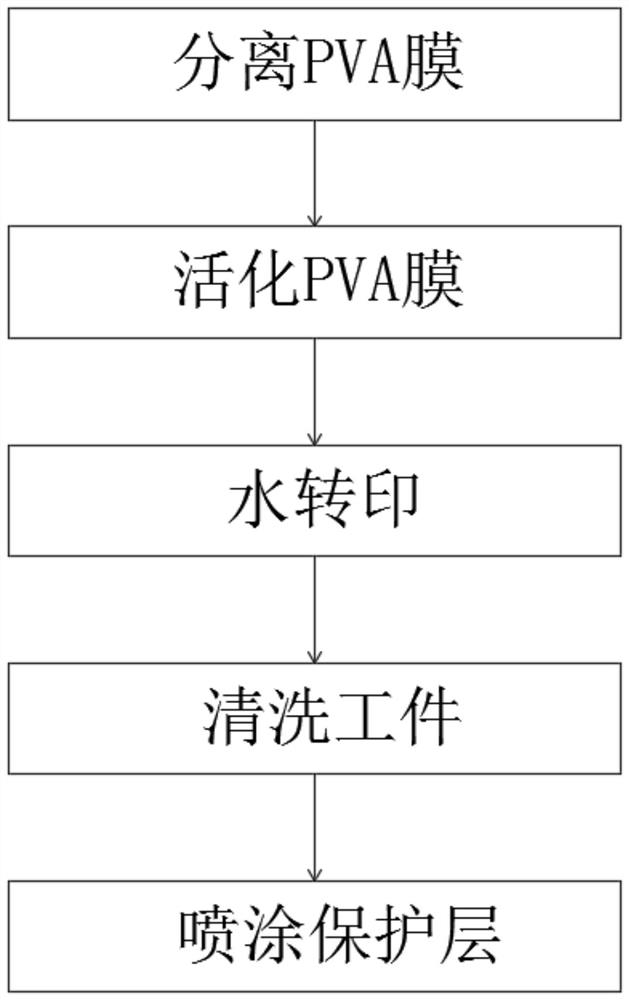

[0040] A preparation method of a digital inkjet printing water transfer film, comprising the steps of:

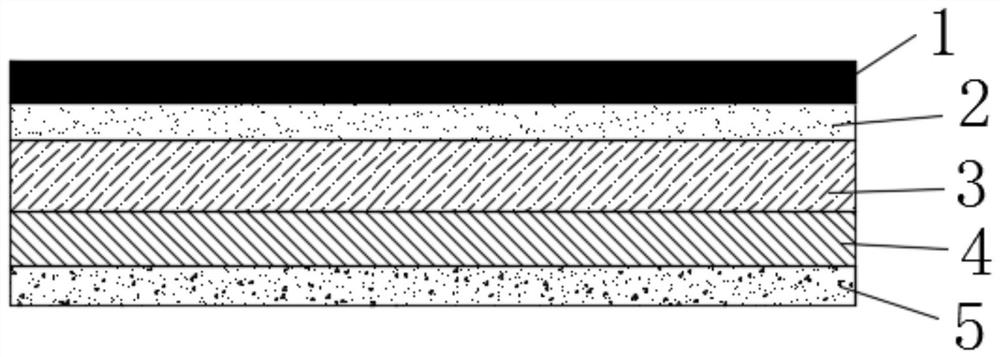

[0041] The first step, prepare the water transfer film, a, thermally press one layer of PET film on the surface of one side of the paper; b, coat one layer of PVA aqueous solution on the side of the PET film to form a PVA film; c, adjust the paper and Humidity of PVA film and heat-pressed leveling paper, then on the side of PVA film, coat one deck polyurethane varnish to form polyurethane varnish layer; d, adjust paper and PVA film humidity and heat-pressed leveling paper;

[0042] In the second step, the image layer is printed, and the image to be transferred is mirror-reversed through the computer, and the reversed image is printed on the polyurethane varnish layer by inkjet printing.

[0043] In the preparation process of the above-mentioned water transfer film, the paper can make the PVA film have the hardness required by the digital inkjet during the digital inkjet pro...

Embodiment 2

[0049] The difference from Example 1 is that the content of each component of the PVA aqueous solution is further preferred, and the proportions are as follows by mass fraction: 18.5% of PVA-1788, 0.9% of soluble starch, 0.4% of glycerin, and 0.3% of non-ionic surface Active agent, 0.01% borax, 0.1% defoamer, the rest is water. The PVA-1788 refers to polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 88%.

Embodiment 3

[0051] For the humidity adjustment part of step c and step d in embodiment 1, a plurality of experimental groups are set up, so that the water content of the PVA film after two humidity adjustments is different, so as to verify the influence of the water content of the PVA film on the transfer. Select part of the test data and get the results shown in the following table:

[0052] Moisture content of basement film (%) Flatness of basement membrane Curl rate of transfer base film (%) Transfer suitability 2.3 poor 38 The pattern is greatly deformed 2.8 poor 32 Distorted, blurred pattern 3.5 basically no deformation 15 The pattern is clear and there is no deformation 4.2 no deformation 11 The pattern is clear and there is no deformation 10.3 Severely deformed 45 cannot transfer 12.7 Severely deformed 57 cannot transfer

[0053] The curl rate is the ratio of the area of the base film that does not float on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com