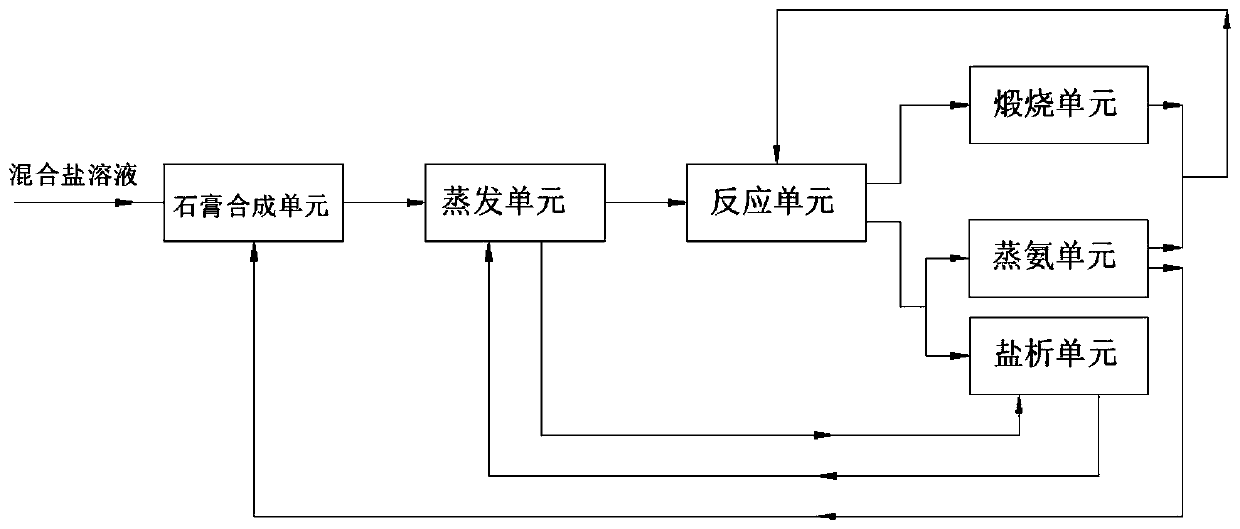

Resourceful treatment system for mixed salt solution and resourceful treatment method thereof

A treatment system and treatment method technology, which is applied in the field of mixed salt solution treatment, can solve the problems of limited use, unavailability of sodium chloride and sodium sulfate, difficult raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

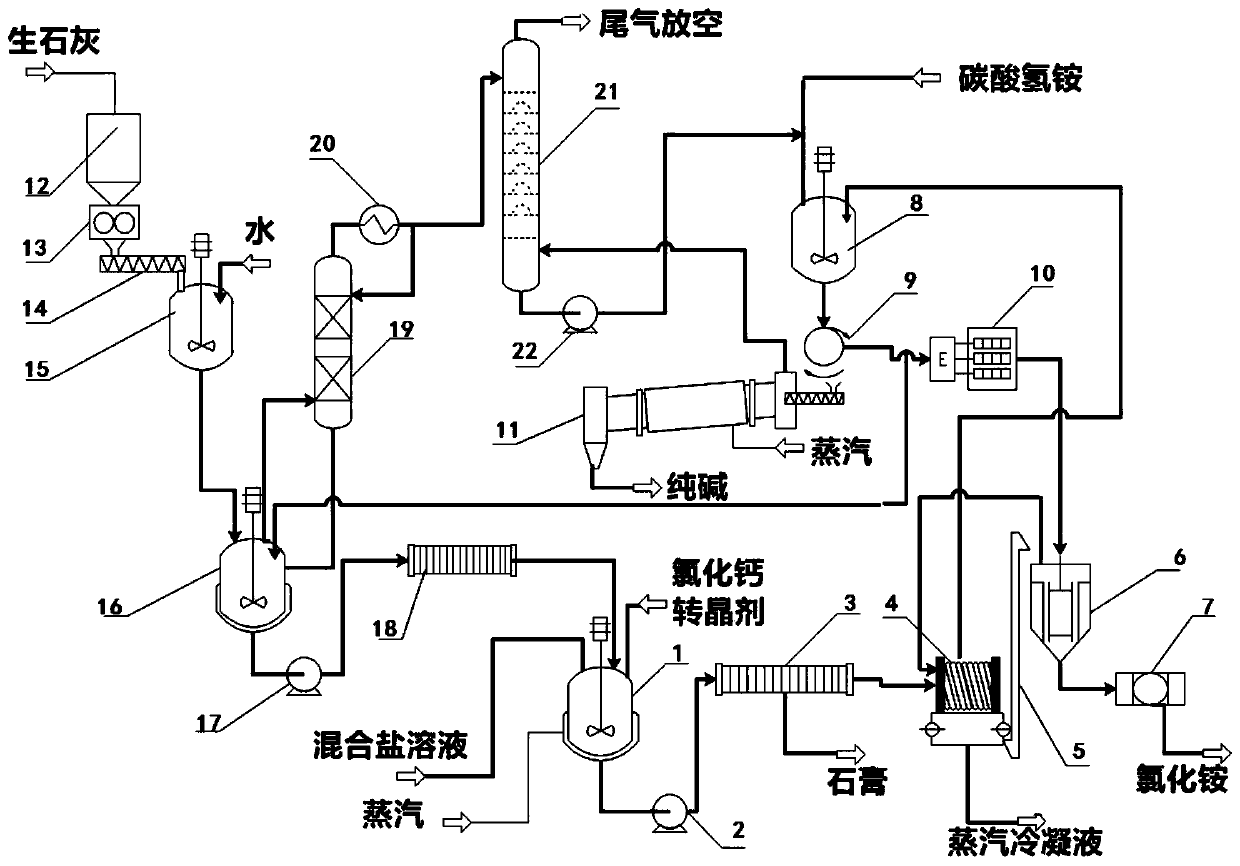

Embodiment 1

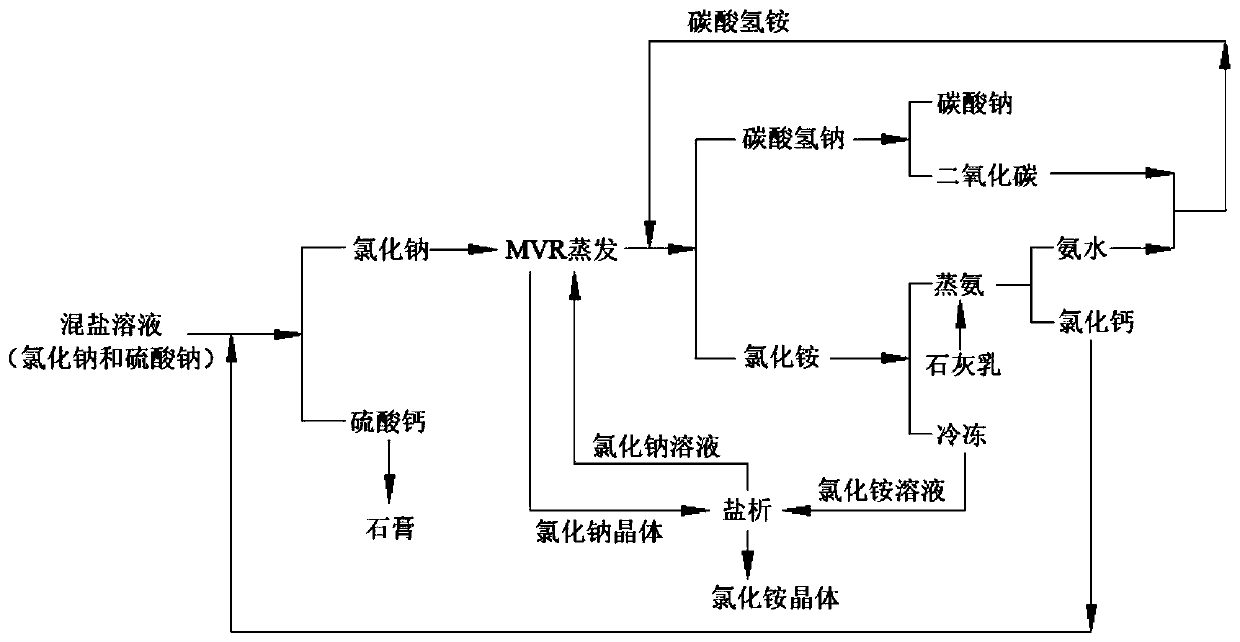

[0102] The resource processing system provided by the specific embodiment is used to carry out resource processing of the mixed salt solution, and the specific processing process includes the following steps:

[0103] (1) by 1m 3 The mixed solution containing sodium chloride and sodium sulfate is used as the calculation basis, the content of sodium chloride is 60g / L, the content of sodium sulfate is 100g / L, the total content of the two is 160g / L, and the specific gravity of the mixed salt solution is 1100kg / m 3 , feed the mixed salt solution into the gypsum synthesis unit 1, the feed temperature is 40°C, and 0.42m 3 Calcium chloride solution is subjected to high-temperature synthesis reaction, the concentration of calcium chloride solution is 200g / L, and the specific gravity of 200g / L calcium chloride solution is 1155Kg / m 3 , the total amount of the mixed salt solution and calcium chloride solution is 1585kg, the reaction temperature of the high temperature synthesis reaction...

Embodiment 2

[0112] The resource processing system provided by the specific embodiment is used to carry out resource processing of the mixed salt solution, and the specific processing process includes the following steps:

[0113] (1) by 1m 3 The mixed solution containing sodium chloride and sodium sulfate is used as the calculation basis, the content of sodium chloride is 80g / L, the content of sodium sulfate is 120g / L, the total content of the two is 200g / L, and the specific gravity of the mixed salt solution is 1130kg / m 3 , feed the mixed salt solution into the gypsum synthesis unit 1, the feed temperature is 50°C, and 0.56m 3 Calcium chloride is subjected to high-temperature synthesis reaction, the concentration of calcium chloride solution is 180g / L, and the specific gravity of 180g / L calcium chloride solution is 1138kg / m 3 , the total amount of the mixed salt solution and calcium chloride solution is 1767kg, the reaction temperature of the high temperature synthesis reaction is 105°C...

Embodiment 3

[0122] The resource processing system provided by the specific embodiment is used to carry out resource processing of the mixed salt solution, and the specific processing process includes the following steps:

[0123] (1) by 1m3 The mixed solution containing sodium chloride and sodium sulfate is used as the calculation basis, the content of sodium chloride is 100g / L, the content of sodium sulfate is 80g / L, the total content of the two is 180g / L, and the specific gravity of the mixed salt solution is 1118kg / m 3 , feed the mixed salt solution into the gypsum synthesis unit 1, the feed temperature is 42°C, and 0.42m 3 Calcium chloride is subjected to high-temperature synthesis reaction, the concentration of calcium chloride solution is 160g / L, and the specific gravity of 160g / L calcium chloride solution is 1125kg / m 3 , the total amount of the mixed salt solution and calcium chloride solution is 1590kg, the reaction temperature of the high-temperature synthesis reaction is 103°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com