Preparation method of cerium oxide particles for coating

A cerium oxide and particle technology, which is applied in the field of preparation of cerium oxide particles for coating, can solve the problems of difficult densification of cerium oxide, affect film quality, structural transformation, etc., and achieve the effects of improving fluidity, avoiding splashing, and reducing pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing high-purity, high-density, and low-splashing cerium oxide particles includes the following steps:

[0033] Weigh 5000g of cerium oxide powder with a purity of ≥99.99%, add a certain amount of deionized water to granulate to obtain flake cerium oxide, and weigh 5.3kg after granulation. The flake cerium oxide is ground and crushed into fine particles, and the pretreated powder with a particle size of 3 And 5.25g / cm 3 . Place the two blanks together in a smart box-type muffle furnace for high-temperature sintering. The sintering process is: heat up to 400°C for 1h in 3 hours, heat up to 600°C in 2 hours, hold for 1h, and heat up to 1000°C for 1h in 4 hours. The temperature is raised to 1300°C in 4 hours for 1 hour, the temperature is raised to 1400°C in 2 hours, and the temperature is raised to 1550°C for 3 hours.

[0034] The highest sintering temperature is 1550°C. After cooling in a high-temperature furnace, a high-density cerium oxide block is obtain...

Embodiment 2

[0035] Example 2 (comparative example)

[0036] A method for preparing cerium oxide particles includes the following steps:

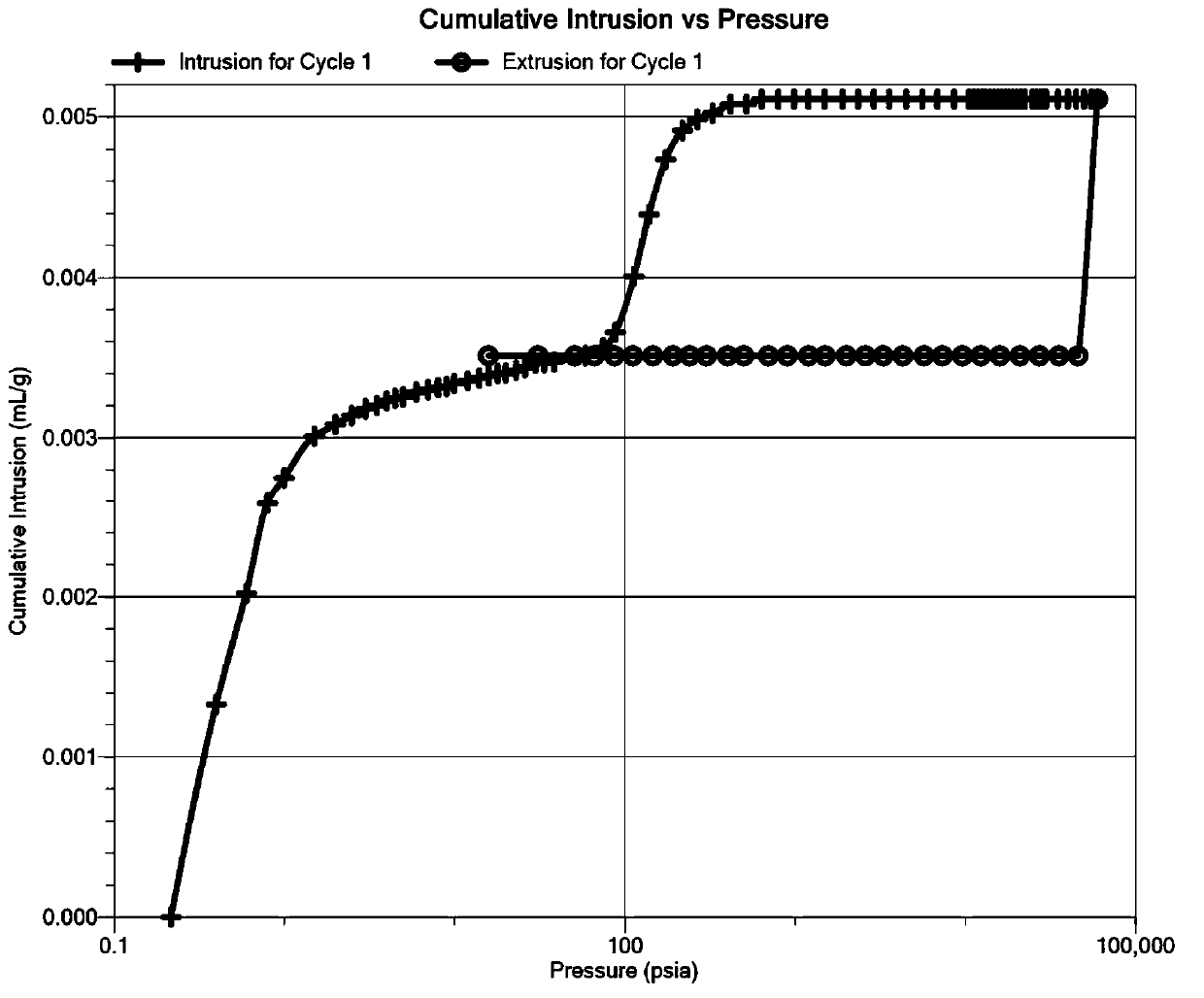

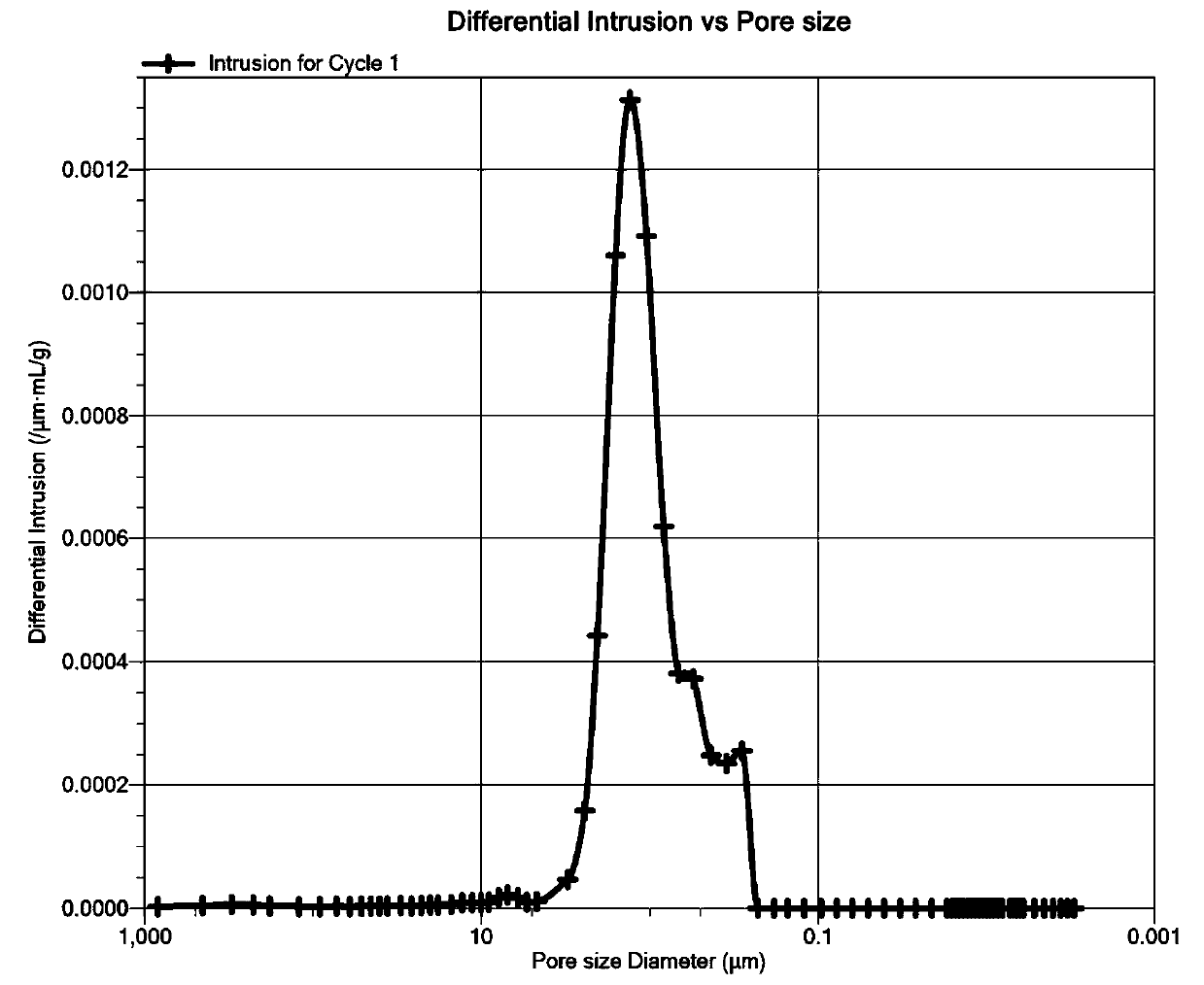

[0037] Weigh 5000g of cerium oxide powder with purity ≥99.99%, add a certain amount of deionized water to granulate into flakes, and weigh 5.3kg after granulation. Grind and crush the flake-shaped cerium oxide, use a special standard sieve to screen out 3-6mm particles, and place them directly in a smart box-type muffle furnace for high-temperature sintering. The sintering process is: heating up to 400 degrees Celsius for 1 hour, The temperature is raised to 600°C in 1 hour for 1 hour, the temperature is raised to 1000°C in 3 hours, and the temperature is raised to 1300°C for 3 hours. The highest sintering temperature is 1300℃, and the mercury intrusion analysis results are as follows image 3 As shown, the obtained cerium oxide particles are measured by mercury intrusion method to test the particle volume density of 5.95g / cm 3 , The relative density is 83....

Embodiment 3

[0038] Example 3 (comparative example)

[0039] A method for preparing cerium oxide particles includes the following steps:

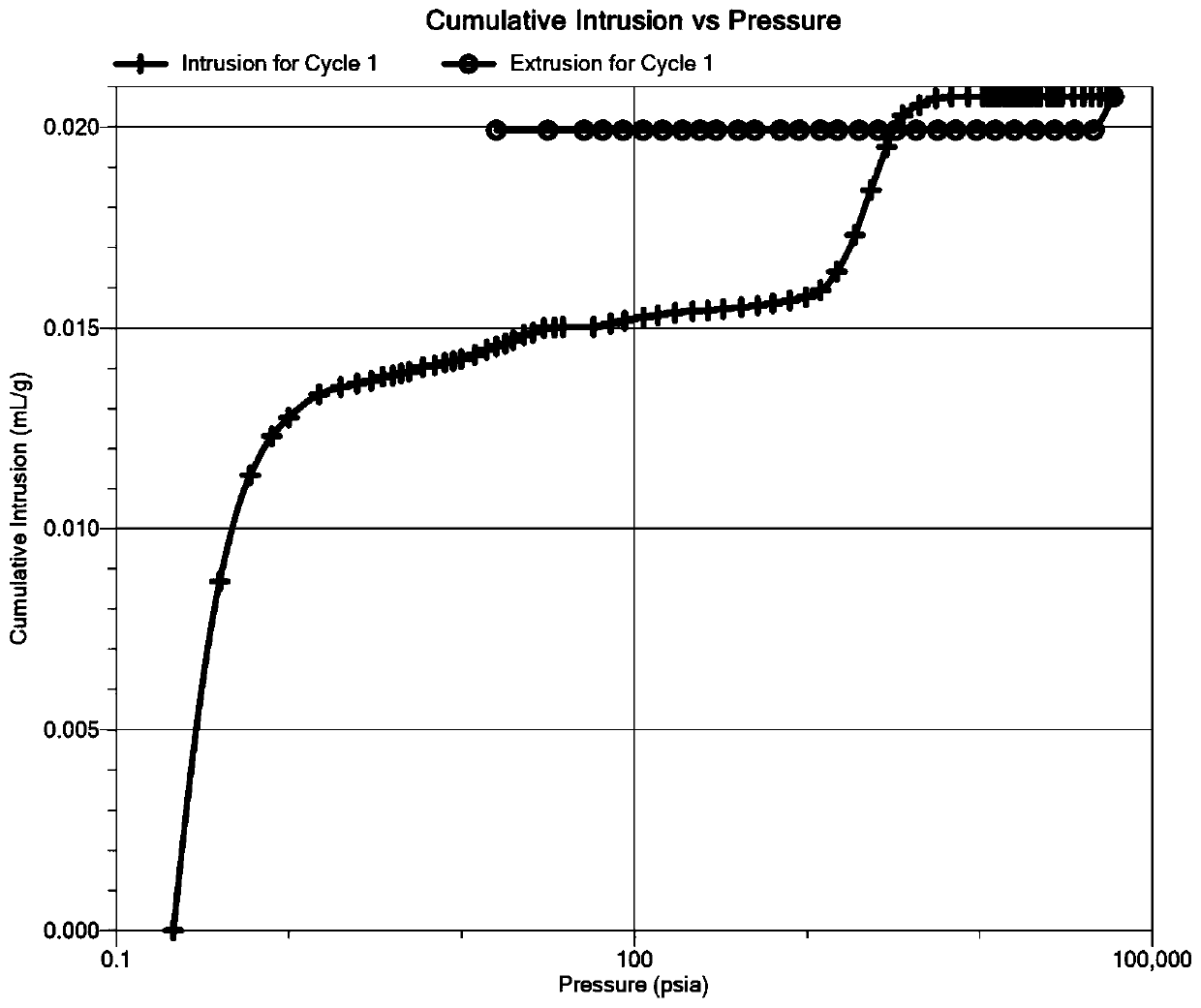

[0040] Weigh 5000g of cerium oxide powder with a purity of ≥99.99%, add a certain amount of deionized water to granulate to obtain flake cerium oxide, and weigh 5.3kg after granulation. The flake cerium oxide is ground and crushed into fine particles, and the pretreated powder with a particle size of 3 . The green body is placed in a smart box-type muffle furnace for high-temperature sintering. The sintering process is as follows: 2 hours to heat up to 400 degrees for 1 hour, 1 hour to 600 degrees for 1 hour, 3 hours to 1000 degrees for 1 hour, 3 hours to heat up Keep the temperature at 1300 degrees for 3 hours. The highest sintering temperature is 1300℃, and the mercury intrusion analysis results are as follows Figure 4 As shown, the obtained cerium oxide particles are measured by mercury intrusion method to test the particle volume density of 6.0295g / cm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com