Method for preparing liquid polyisoprene rubber based on reversible addition-pyrolysis chain transfer radical polymerization and rubber material

A polyisoprene and cracking chain transfer technology, applied in the field of rubber materials, can solve the problems of harsh reaction environment, dangerous storage and use, expensive catalysts, etc., and achieve the effects of less VOC release, easy storage and non-volatile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

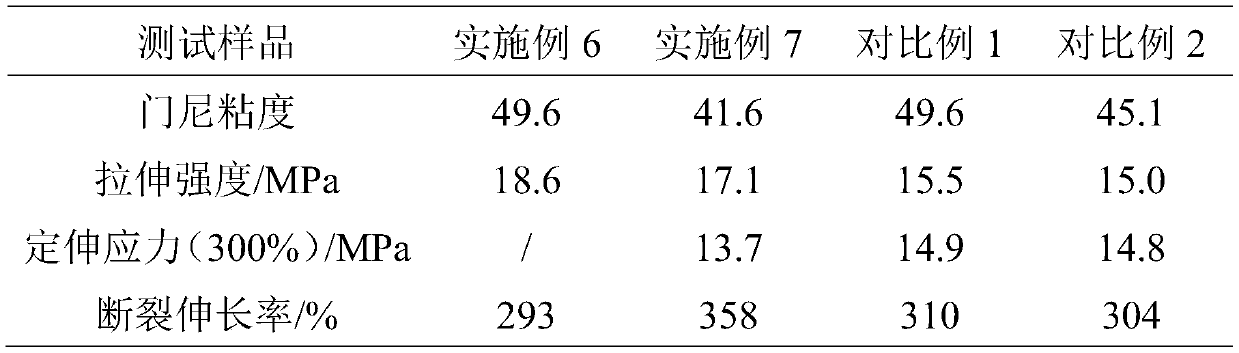

Examples

Embodiment 1

[0025] Preparation of liquid polyisoprene rubber based on RAFT polymerization, specifically:

[0026] Add 45g of 1,4-dioxane, 0.207g of BDAAT, 0.021g of DTBP, and 15g of isoprene into the Erlenmeyer flask in sequence, mix well, transfer the mixture to the reaction kettle, and use liquid nitrogen to The reaction kettle was frozen for 20 minutes, vacuumed with a vacuum pump and nitrogen was reciprocated three times, a pressure of 2 MPa was applied with nitrogen, and the reaction was carried out at 126°C for 10 hours. The product was precipitated with methanol to obtain a yellow liquid product, which was dried in a vacuum oven to constant weight. After calculation, the yield is 19.0%, Mn=0.96×10 4 , Mw / Mn=1.69.

Embodiment 2

[0028] Preparation of liquid polyisoprene rubber based on RAFT polymerization, specifically:

[0029] Add 45g of 1,4-dioxane, 0.5354g of DDMAT, 0.0430g of DTBP, and 15g of isoprene into the Erlenmeyer flask successively, mix well, transfer the mixed solution to the reaction kettle, and use liquid nitrogen to The reaction kettle was frozen for 20 minutes, vacuumed with a vacuum pump and nitrogen was reciprocated three times, a pressure of 2 MPa was applied with nitrogen, and the reaction was carried out at 126°C for 10 hours. The product was precipitated with methanol to obtain a yellow liquid product, which was dried in a vacuum oven to constant weight. After calculation, the yield is 27.0%, Mn=0.49×10 4 , Mw / Mn=1.23.

Embodiment 3

[0031] Preparation of liquid polyisoprene rubber based on RAFT polymerization, specifically:

[0032] Add 45g of 1,4-dioxane, 0.2677g of DDMAT, 0.0215g of DTBP, and 15g of isoprene to the Erlenmeyer flask successively, mix well, transfer the mixed solution to the reaction kettle, and use liquid nitrogen to The reaction kettle was frozen for 20 minutes, evacuated by a vacuum pump to pass nitrogen gas back and forth three times, and a pressure of 2 MPa was applied with nitrogen gas, and reacted at 126°C for 10 hours. The product was precipitated with methanol to obtain a yellow liquid product, which was dried in a vacuum oven to constant weight. After calculation, the yield is 21.6%, Mn=0.7×10 4 , Mw / Mn=1.32.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com