Dynamic covalent cross-linked cellulose-based bioplastic, wood-plastic composite material and preparation method and application thereof

A cellulose-based, covalent cross-linking technology, applied in the field of material chemistry, can solve the problems that plastics cannot be chemically and biologically degraded, cannot be sustainable and degradable, and the synthesis process is complex, so as to improve interfacial compatibility, Ease of industrial production and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

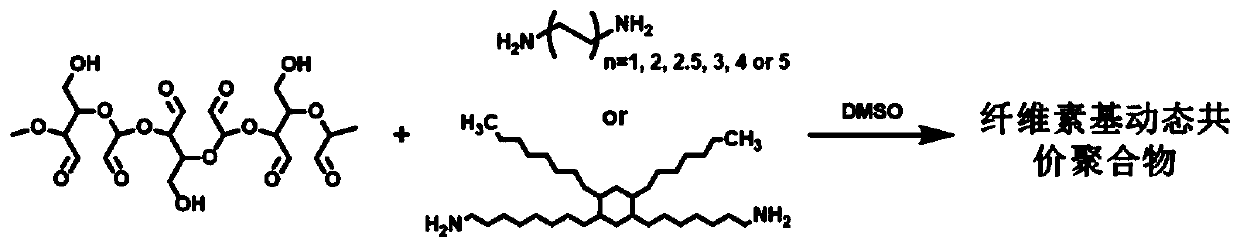

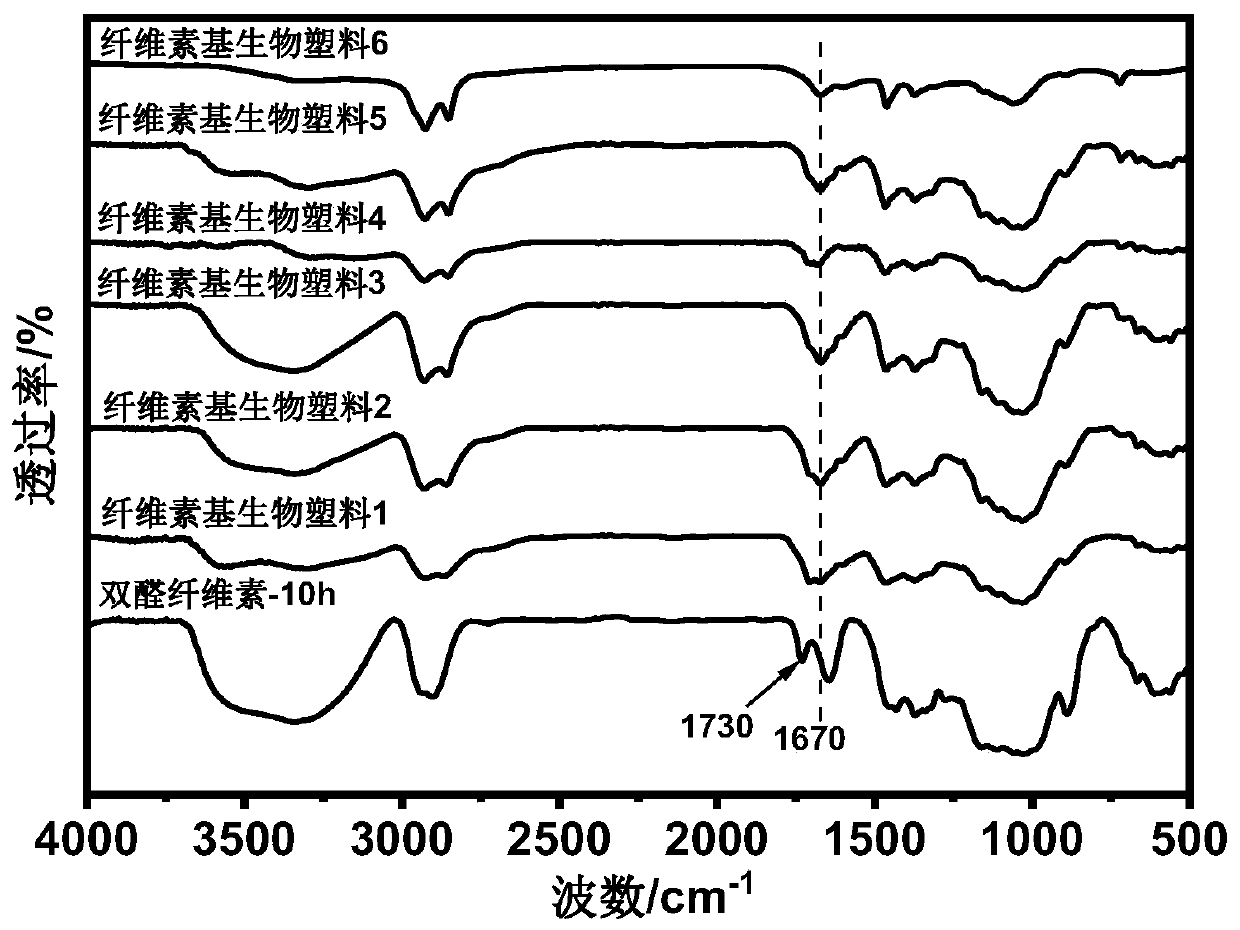

[0063] This example provides a method for preparing cellulose-based bioplastic 1 by polymerizing dialdehyde cellulose and butylenediamine.

[0064] The preparation method of the cellulose-based bioplastic 1 comprises the following steps;

[0065] (1) Preparation of dialdehyde cellulose: disperse 2 g of microcrystalline cellulose in 250 ml of water, add 3.2 g of sodium periodate, and react at 50°C for 10 hours to obtain dialdehyde cellulose;

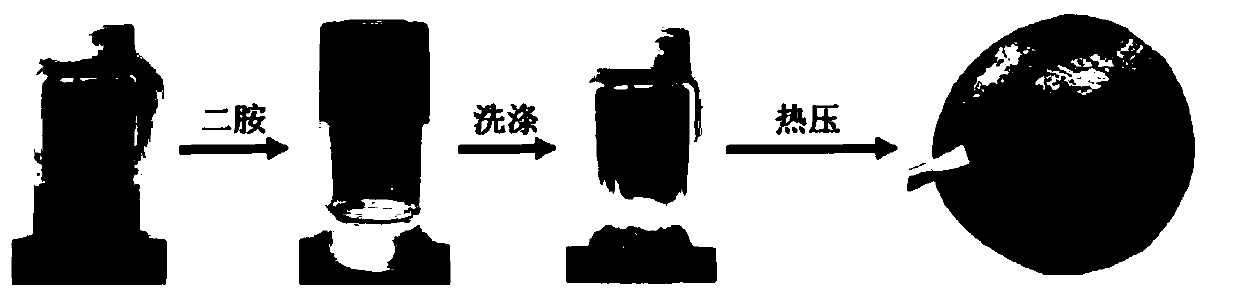

[0066] (2) Synthesis of dynamically covalently cross-linked cellulose gels: such as figure 1 and figure 2 As shown, dissolve 0.5g dialdehyde cellulose in 8ml DMSO for 1.5h, add butanediamine according to the molar ratio of aldehyde group to amine group of 1:1, and react at room temperature for 8h to obtain 100% dynamically covalently crosslinked fibers plain gel;

[0067] (3) Obtaining cellulose-based dynamic covalent polymer powder: fully wash the cellulose gel with ethanol, and then vacuum-dry it at 60° C. for 12 hours to obtain cel...

Embodiment 2

[0070] This example provides a method for preparing cellulose-based bioplastic 2 by polymerizing dialdehyde cellulose and pentamethylenediamine.

[0071] The preparation method of the cellulose-based bioplastic 2 comprises the following steps;

[0072] (1) Preparation of dialdehyde cellulose: disperse 2 g of microcrystalline cellulose in 250 ml of water, add 3.2 g of sodium periodate, and react at 50°C for 10 hours to obtain dialdehyde cellulose;

[0073] (2) Synthesis of dynamically covalently cross-linked cellulose gels: such as figure 1 and figure 2 As shown, dissolve 0.5g dialdehyde cellulose in 8ml DMSO for 1.5h, add pentamethylenediamine according to the molar ratio of aldehyde group to amine group of 1:1, and react at room temperature for 8h to obtain 100% dynamically covalently crosslinked fibers plain gel;

[0074] (3) Obtaining cellulose-based dynamic covalent polymer powder: fully wash the cellulose gel with ethanol, and then vacuum-dry it at 60° C. for 12 hours...

Embodiment 3

[0077] This example provides a method for preparing cellulose-based bioplastic 3 by polymerizing dialdehyde cellulose and hexamethylenediamine.

[0078] The preparation method of the cellulose-based bioplastic 3 comprises the following steps;

[0079] (1) Preparation of dialdehyde cellulose: disperse 2 g of microcrystalline cellulose in 250 ml of water, add 3.2 g of sodium periodate, and react at 50°C for 10 hours to obtain dialdehyde cellulose;

[0080] (2) Synthesis of dynamically covalently cross-linked cellulose gels: such as figure 1 and figure 2 As shown, dissolve 0.5g of dialdehyde cellulose in 8ml of DMSO for 1.5h, add hexamethylenediamine according to the molar ratio of aldehyde group to amine group of 1:1, and react at room temperature for 8h to obtain 100% dynamically covalently crosslinked fibers plain gel;

[0081] (3) Obtaining cellulose-based dynamic covalent polymer powder: fully wash the cellulose gel with ethanol, and then vacuum-dry it at 60° C. for 12 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com