Environment-friendly flame-retardant polypropylene-nylon alloy material and preparation method thereof

A technology of flame-retardant polypropylene and alloy materials, which is applied in the field of alloy materials, can solve the problems of reduced physical properties of flame-retardant polypropylene, no performance and cost advantages, and large amount of flame retardants added, so as to improve flame-retardant properties and broaden the Application, Effect of Ignition Temperature Raise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

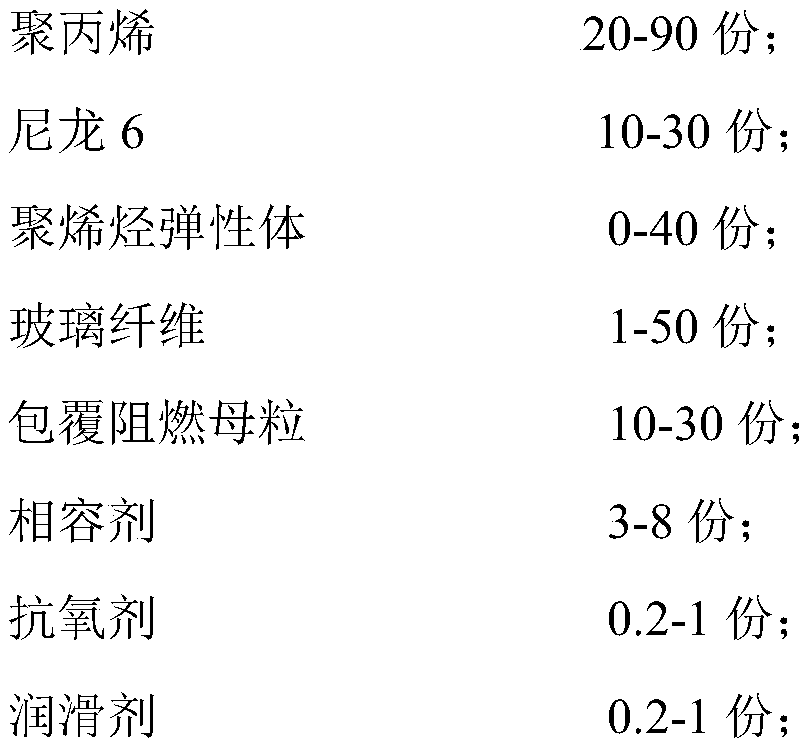

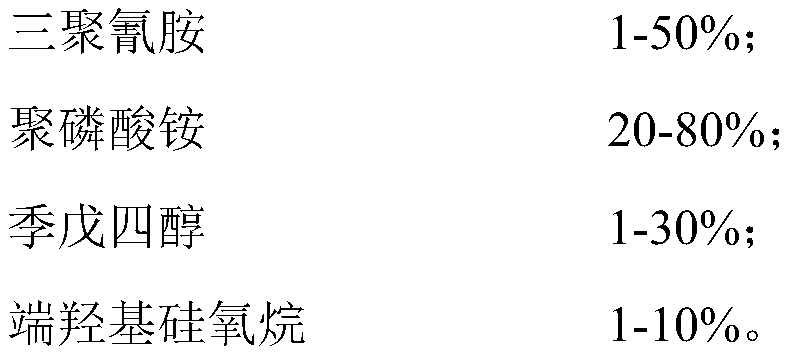

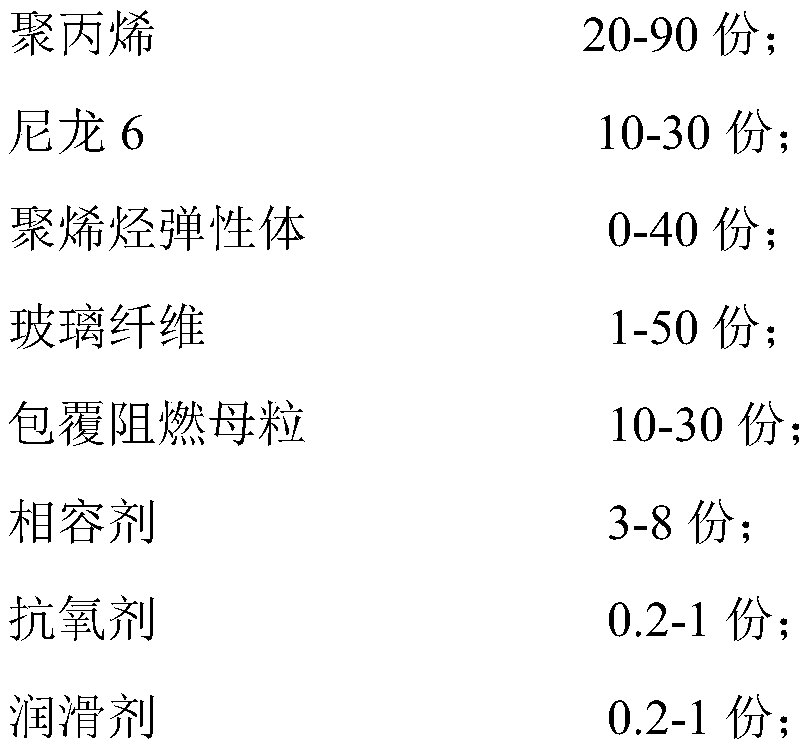

Method used

Image

Examples

Embodiment 1-4

[0035] raw material Example 1 Example 2 Example 3 Example 4 polypropylene 50 servings 48 servings 35 servings 33 servings PA6 15 servings 15 servings PP grafted maleic anhydride 5 servings 5 servings 5 servings 5 servings glass fiber 20 servings 20 servings 20 servings 20 servings Hydroxysiloxane 2 servings 2 servings melamine 4 parts 4 parts 4 parts 4 parts Ammonium polyphosphate 15 servings 15 servings 15 servings 15 servings Pentaerythritol 5 servings 5 servings 5 servings 5 servings Processing aids 1 serving 1 serving 1 serving 1 serving

[0036] After the above components are fully mixed in a high-speed mixer, they are extruded and granulated by a twin-screw extruder. The extrusion temperature is controlled at 180°C and the screw speed is controlled at 400r / min to obtain the product. The obtained products are subjected to relevant experi...

Embodiment 5-8

[0040]

[0041]

[0042] After the above components are fully mixed in a high-speed mixer, they are extruded and granulated by a twin-screw extruder. The extrusion temperature is controlled at 180°C and the screw speed is controlled at 400r / min to obtain the product. The obtained products are subjected to relevant experimental tests, the flexural strength and flexural modulus are tested according to GB / T9341, the notched impact is tested according to GB / T1843, the flame retardancy is tested according to ASTM UL94, and the glow wire ignition temperature is tested according to IEC60695.2-12 . The test results are shown in the table below:

[0043] project Example 5 Example 6 Example 7 Example 8 Bending strength 105 108 103 104 Flexural modulus 4950 5200 5320 5280 Flame retardant properties V-0(3.2mm) V-0(3.2mm) V-0(1.6mm) V-0(1.6mm) glow wire ignition temperature 775 775 800 800 Notched impact strength (KJ / M 2 ...

Embodiment 5

[0044] Example 5 is a method of directly adding various flame retardants, and the added content is equivalent to 26% coated flame retardant masterbatch. Comparing Example 5 and Example 8, it can be seen that the method of adding masterbatches improves the flame retardant of the system. The ignition level has been increased from 3.2mmV-0 to 1.6mmV-0, and the glow wire ignition temperature has also been improved. Comparing Example 5 and Example 6, the amount of coating masterbatch added in Example 6 is only 22%, but the flame retardant performance of Example 6 has fully reached the effect of Example 5, indicating that the same flame retardant level coating masterbatch is achieved The use of pellets can reduce the amount of flame retardants.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com