Preparation method of high-strength hard plastic alloy granules

A hard plastic and high-strength technology, applied in the field of plastic alloys and plastics, can solve problems such as poor weather resistance and easy cracking of polystyrene, and achieve the effects of improving aging resistance, reducing environmental pressure, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

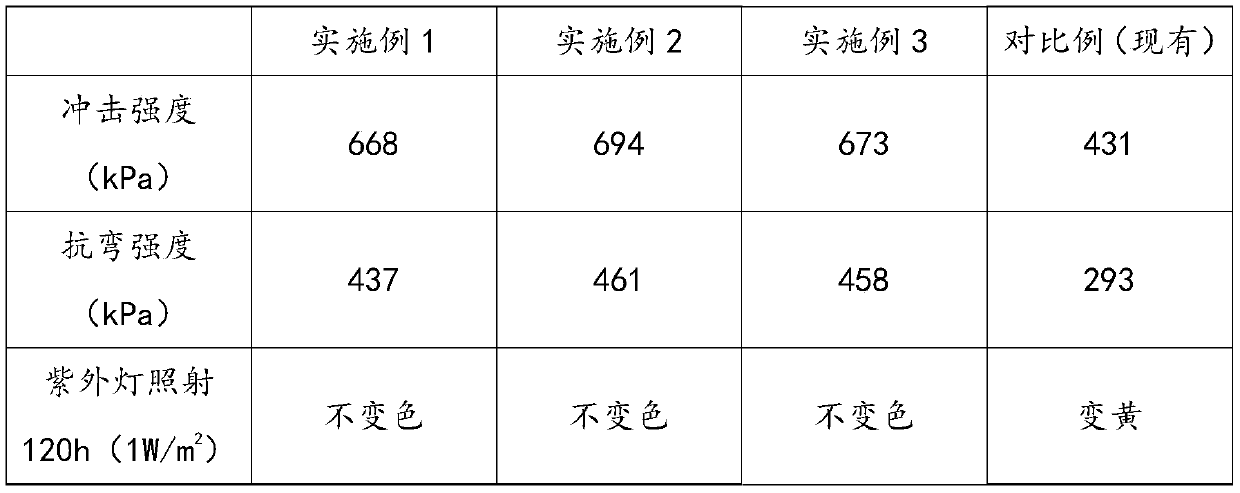

Examples

Embodiment 1

[0021] A method for preparing high-strength hard plastic alloy pellets, characterized in that it comprises the following steps:

[0022] Step 1, adding polystyrene to toluene and stirring evenly, distilling under constant temperature and reduced pressure until a small amount of crystals are precipitated, cooling and filtering to obtain a saturated polystyrene toluene liquid;

[0023] Step 2: Add the ethylene-vinyl acetate copolymer emulsion to the saturated polystyrene toluene liquid and stir evenly at low temperature to obtain a saturated polystyrene mixed liquid

[0024] Step 3, adding phenyltrichlorosilane to the saturated polystyrene mixed liquid for low-temperature ultrasonic dispersion for 20 minutes, and then filtering the insoluble matter to obtain a mixed toluene liquid;

[0025] Step 4, put the mixed toluene liquid into the mold to evaporate at constant temperature to form viscous granules, and then place it in a sealed reaction kettle for ventilation reaction for 2 ...

Embodiment 2

[0033] A method for preparing high-strength hard plastic alloy pellets, characterized in that it comprises the following steps:

[0034] Step 1, adding polystyrene to toluene and stirring evenly, distilling under constant temperature and reduced pressure until a small amount of crystals are precipitated, cooling and filtering to obtain a saturated polystyrene toluene liquid;

[0035] Step 2: Add the ethylene-vinyl acetate copolymer emulsion to the saturated polystyrene toluene liquid and stir evenly at low temperature to obtain a saturated polystyrene mixed liquid

[0036] Step 3, adding phenyltrichlorosilane to the saturated polystyrene mixed liquid for 50 minutes of ultrasonic dispersion at low temperature, and then filtering the insoluble matter to obtain a mixed toluene liquid;

[0037] Step 4, put the mixed toluene liquid into the mold and evaporate at constant temperature to form viscous granules, and then place them in a sealed reaction kettle for ventilation and react ...

Embodiment 3

[0045] A method for preparing high-strength hard plastic alloy pellets, characterized in that it comprises the following steps:

[0046] Step 1, adding polystyrene to toluene and stirring evenly, distilling under constant temperature and reduced pressure until a small amount of crystals are precipitated, cooling and filtering to obtain a saturated polystyrene toluene liquid;

[0047] Step 2: Add the ethylene-vinyl acetate copolymer emulsion to the saturated polystyrene toluene liquid and stir evenly at low temperature to obtain a saturated polystyrene mixed liquid

[0048] Step 3, adding phenyltrichlorosilane to the saturated polystyrene mixed solution for low-temperature ultrasonic dispersion for 40 minutes, and then filtering the insoluble matter to obtain a mixed toluene solution;

[0049] Step 4, put the mixed toluene liquid into the mold to evaporate at constant temperature to form viscous granules, and then place it in a sealed reaction kettle for ventilation reaction fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com