Large-surface-tension, small-gap, high-smoothness and low-friction antifouling paint

A technology of surface tension and anti-fouling coatings, applied in the field of coatings, can solve the problems of high surface tension, low smoothness, and small voids, and achieve the effects of high surface tension, improved compatibility, and small voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to illustrate the present invention more clearly, the following will be further described in conjunction with various embodiments.

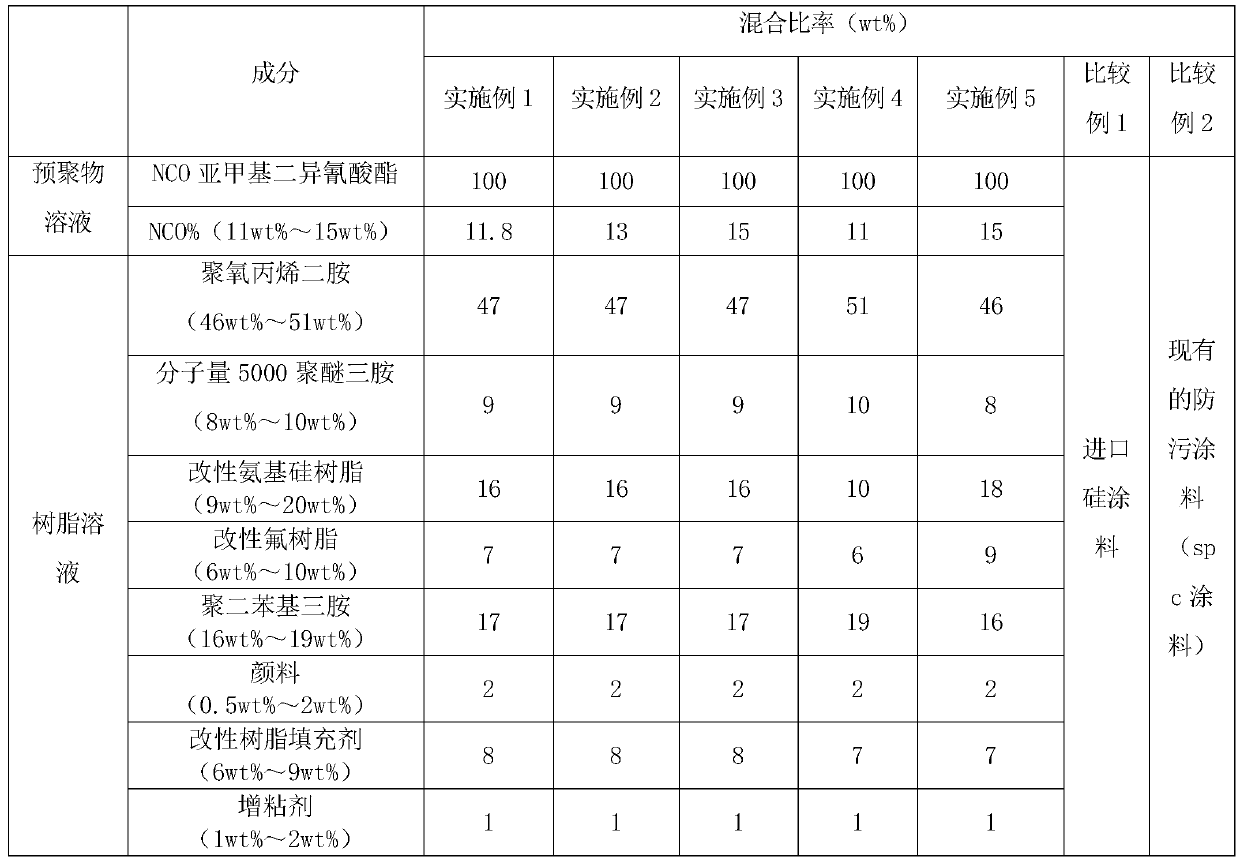

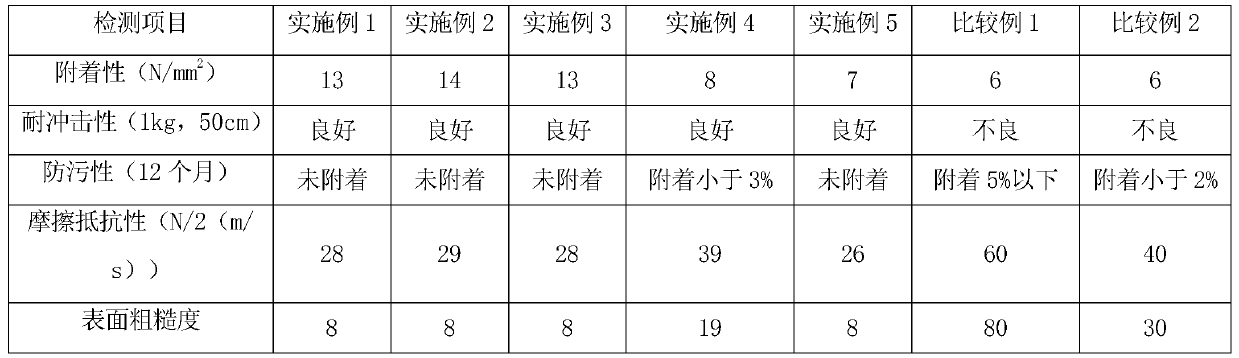

[0024] Table 1 shows the component content ratios of Examples 1 to 5 of the present invention's large surface tension, small voids, high smoothness and low friction type antifouling coatings

[0025] Among them, the components of the resin solution in Examples 1 to 3 are fixed as 47wt% of polyoxypropylene diamine, 9wt% of polyethertriamine with a molecular weight of 5000, 16wt% of modified amino silicone resin, 7wt% of modified fluororesin, poly Diphenylamine 17wt%, pigment 2wt%, modified filler 8wt%, tackifier 1wt%, NCO content of methylene diisocyanate in the prepolymer solution were 11.8wt%, 13wt%, 15wt%.

[0026] Among them, the modified resin filler, pigment, and tackifier in the resin solution components in Examples 4 to 5 are respectively fixed at 7wt%, 2wt%, and 1wt%, and the polyoxypropylenediamine in the resin solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com