Temporary plugging workover fluid and preparation method thereof

A technology of workover fluid and expansion inhibitor, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., and can solve the problem of high water-absorbing resin expansion multiple, small temporary plugging layer pressure bearing capacity, and low temporary plugging success rate and other problems, to achieve the effects of easy degradation, improved pressure bearing capacity, and good pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] In the preparation process of the flour balls, the amount of water added can be 30% to 35% of the weight of the wheat flour, so that the flour and the floating pearls can be mixed evenly and have plasticity.

[0049] In the preparation process of resin balls, the addition amount of isopropanol and silane coupling agent can be 20% to 25% and 2% to 3% of the weight of petroleum resin respectively. As an interface modifier, it can make the petroleum resin and the float more easily bonded together.

[0050] It should be noted that, in the embodiment of the present invention, the floating ball has a hollow structure, and the prepared flour balls and resin balls are also hollow structures, which makes the flour balls and resin balls have lower densities.

[0051] The diameter of the polyvinyl alcohol fiber can be 0.01 mm, 0.02 mm, 0.03 mm, etc., and the length can be 3 mm, 4 mm, 5 mm, etc.

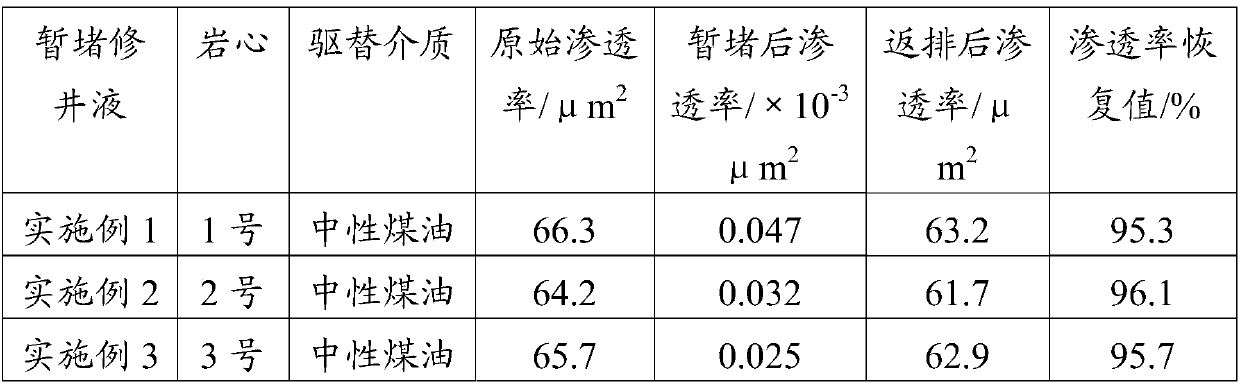

[0052] Wherein, the water absorption ratio of the resin ball in the embodiment of th...

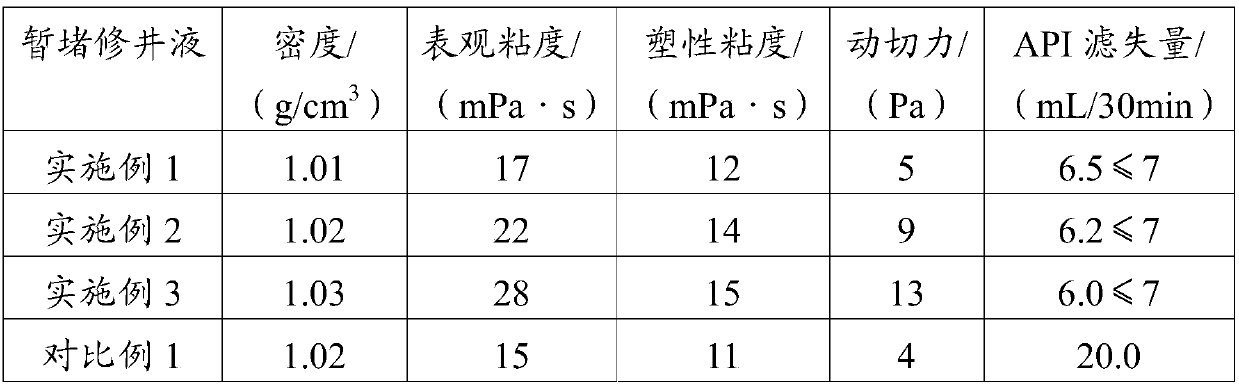

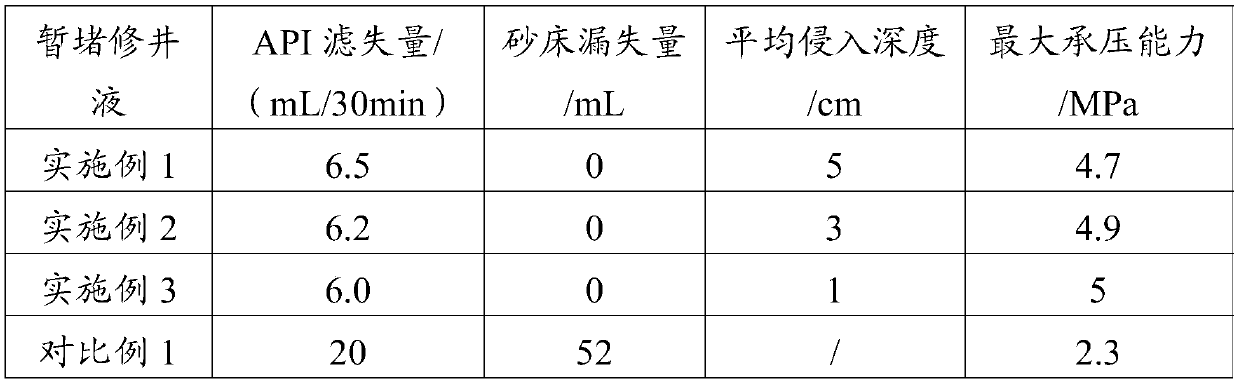

Embodiment 1

[0083]This embodiment provides a temporary plugging and workover fluid, which is prepared by the following method: add 95.87 parts by weight of tap water to the stirring tank, and slowly add 0.10 parts by weight of hydroxysulfite to the stirring tank through the feeding funnel under the stirring state. An aqueous solution of ethyl diphosphonic acid tetrasodium salt and amino trimethylene phosphonic acid pentasodium salt was stirred for 45 minutes. Wherein, the total mass percentage of tetrasodium salt of hydroxyethylene diphosphonic acid and pentasodium salt of aminotrimethylene phosphonic acid is 28%, tetrasodium salt of hydroxyethylene diphosphonic acid and pentasodium salt of aminotrimethylene phosphonic acid The mass ratio is 1:0.8. Under stirring conditions, 0.29 parts by weight of biopolymers with a molecular weight of 2 million to 6 million were added to the stirring tank, stirred for 2.2 hours, and the dynamic shear force of the mixed fluid was measured as 2 Pa by usin...

Embodiment 2

[0087] This embodiment provides a temporary plugging and workover fluid, which is prepared by the following method: add 92.99 parts by weight of tap water to the stirring tank, and slowly add 0.4 parts by weight of hydroxysulfite to the stirring tank through the feeding funnel under the stirring state. An aqueous solution of ethyl diphosphonic acid tetrasodium salt and amino trimethylene phosphonic acid pentasodium salt was stirred for 50 min. Wherein, the total mass percentage of hydroxyethylene diphosphonic acid tetrasodium salt and aminotrimethylene phosphonic acid pentasodium salt is 30%, hydroxyethylene diphosphonic acid tetrasodium salt and aminotrimethylene phosphonic acid pentasodium salt The mass ratio is 1:1.2. Under stirring conditions, add 0.4 parts by weight of a biopolymer with a molecular weight of 2 million to 6 million into the stirring tank, stir for 2.5 hours, and measure the dynamic shear force of the mixed fluid with a Marsh funnel for drilling fluid to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com