Multifunctional composite vacuum preloading treatment method for sludge with high water content and high organic matter

A technology with high water content and treatment method, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of difficulty in popularization and application, immaturity, high price, etc., to increase sludge permeability, increase permeability and Dehydration, the effect of enhancing structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

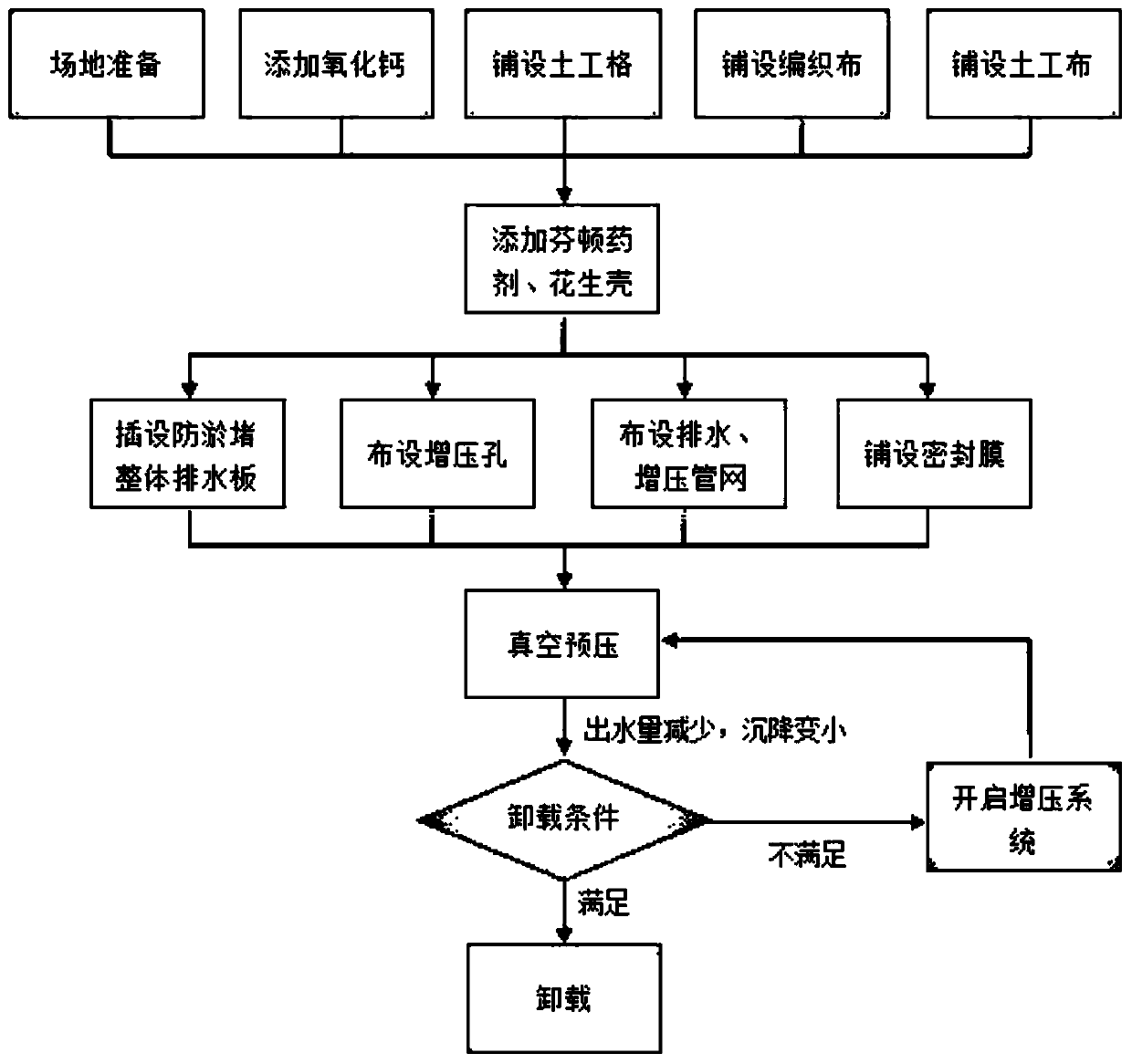

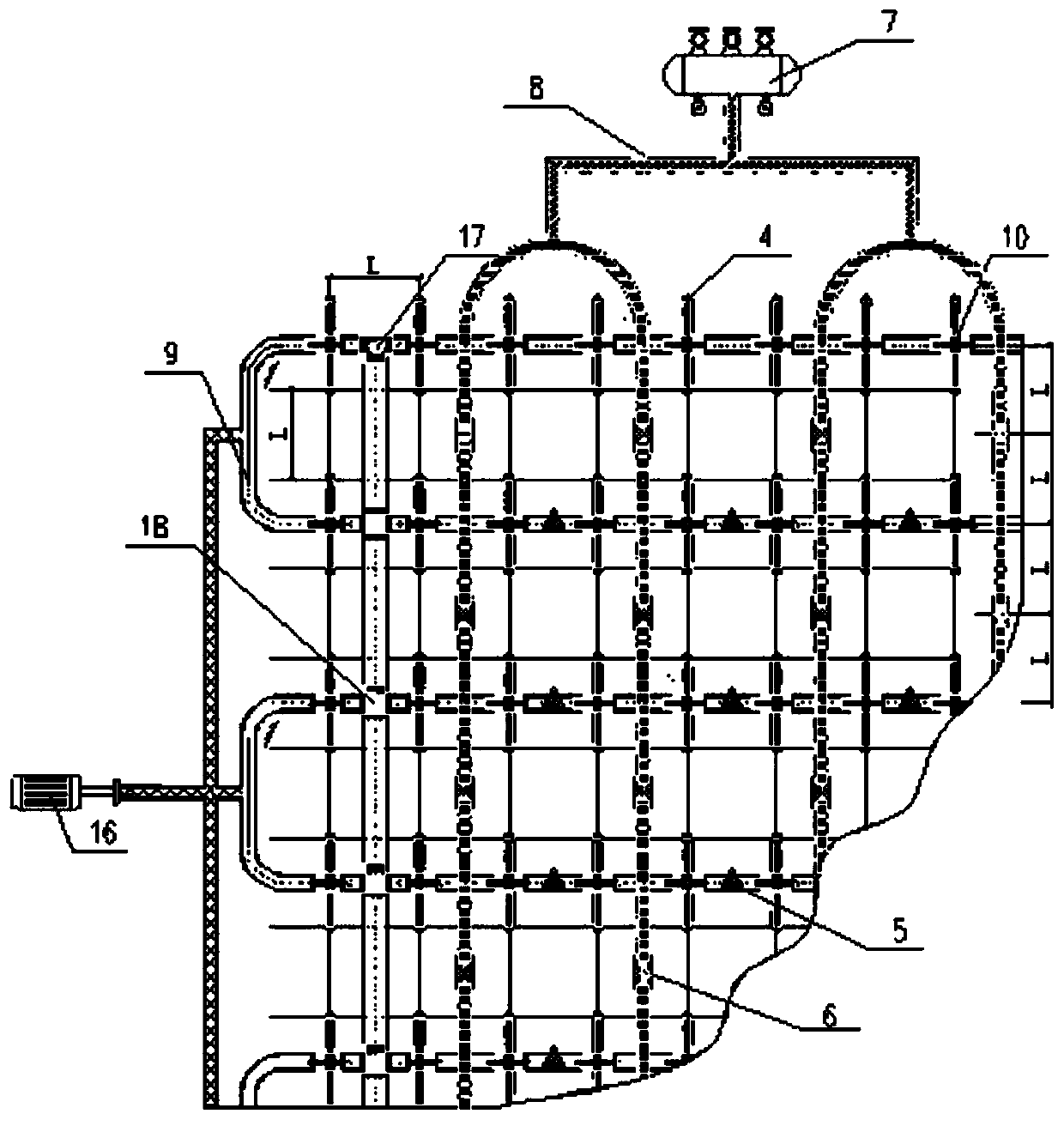

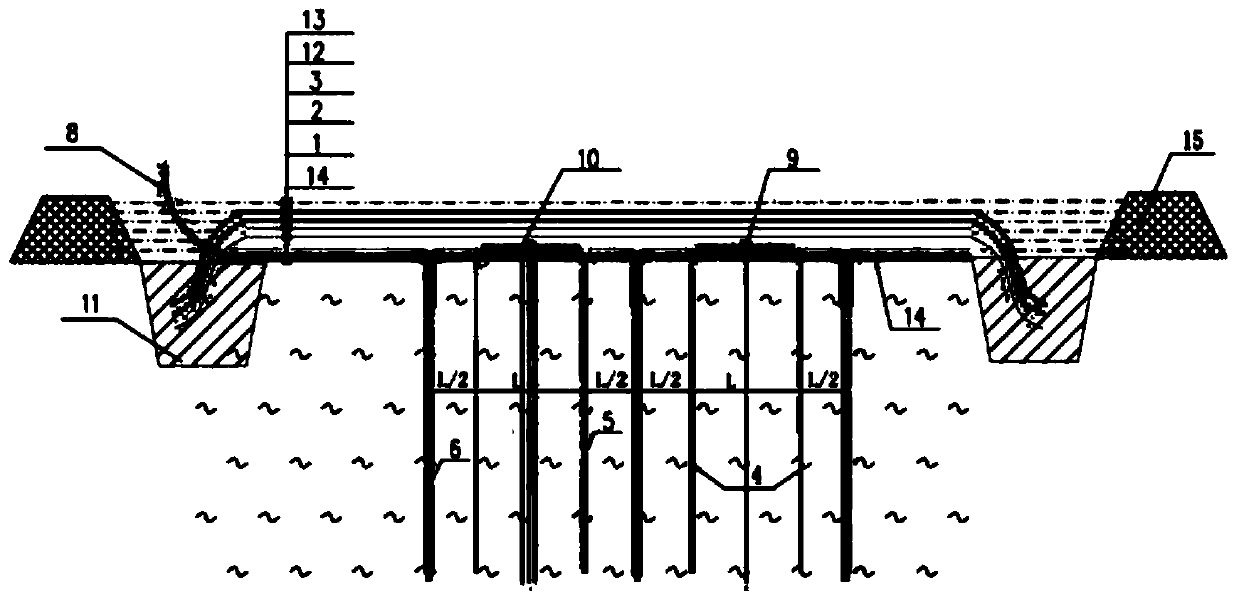

[0040] like figure 1 , figure 2 and image 3 As shown, the multifunctional composite vacuum preloading treatment method for sludge with high water content and high organic matter is as follows:

[0041] (1) Site preparation, remove the accumulated water on the surface of the site, clear the weeds in the site, and carry out preliminary site leveling.

[0042] (2) A layer of woven cloth (1) and a layer of geogrid (2) are laid on the site surface (14). The woven fabric can use 280g / m2 BBT PP60-42 / 3.8 woven fabric, and the geogrid can use TGSG20-20 geogrid.

[0043](3) Open holes (5) on the first layer of woven cloth (1) and geogrid (2), and mix 10% calcium oxide with the sludge by a light stirring machine according to the dry weight of the sludge.

[0044] (4) A layer of geotextile (3) geotextile cushion is laid on the geogrid (2). The geotextile can use 200g / m2 short-fiber needle-punched non-woven geotextile. The geotextile laying range should cover the entire reinforceme...

Embodiment 2

[0059] like figure 1 , figure 2 and image 3 As shown, the multifunctional composite vacuum preloading treatment method for sludge with high water content and high organic matter is as follows:

[0060] (1) Site preparation, remove the accumulated water on the surface of the site, clear the weeds in the site, and carry out preliminary site leveling.

[0061] (2) A layer of woven cloth (1) and a layer of geogrid (2) are laid on the site surface (14). The woven fabric can use 280g / m2 BBT PP60-42 / 3.8 woven fabric, and the geogrid can use TGSG20-20 geogrid.

[0062] (3) Open holes (5) on the first layer of woven cloth (1) and geogrid (2), and mix 20% calcium oxide with the sludge by a light stirring machine according to the dry weight of the sludge.

[0063] (4) A layer of geotextile (3) geotextile cushion is laid on the geogrid (2). The geotextile can use 200g / m2 short-fiber needle-punched non-woven geotextile. The geotextile laying range should cover the entire reinforcem...

Embodiment 3

[0078] like figure 1 , figure 2 and image 3 As shown, the multifunctional composite vacuum preloading treatment method for sludge with high water content and high organic matter is as follows:

[0079] (1) Site preparation, remove the accumulated water on the surface of the site, clear the weeds in the site, and carry out preliminary site leveling.

[0080] (2) A layer of woven cloth (1) and a layer of geogrid (2) are laid on the site surface (14). The woven fabric can use 280g / m2 BBT PP60-42 / 3.8 woven fabric, and the geogrid can use TGSG20-20 geogrid.

[0081] (3) Open holes (5) on the first layer of woven cloth (1) and geogrid (2), and mix 30% calcium oxide with the sludge by a light stirring machine according to the dry weight of the sludge.

[0082] (4) A layer of geotextile (3) geotextile cushion is laid on the geogrid (2). The geotextile can use 200g / m2 short-fiber needle-punched non-woven geotextile. The geotextile laying range should cover the entire reinforcemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com