Design and implementation method of PCS7-based continuous process control strategy with recovery process

A technology of process control and realization method, applied in non-electric variable control, control/regulation system, control of multiple variables at the same time, etc., can solve the problems of no recycling, low system output, high energy consumption, etc., to improve energy Utilization rate, increased economic benefits, high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

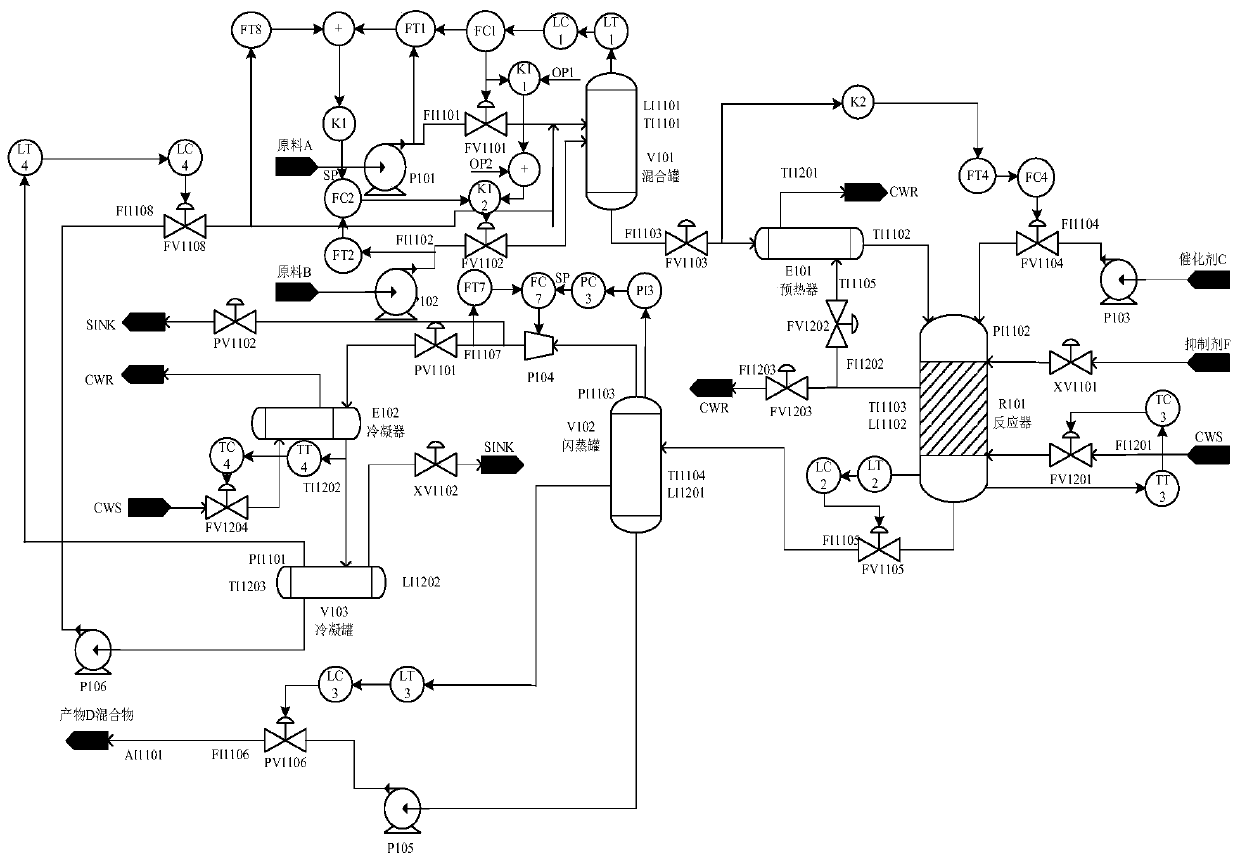

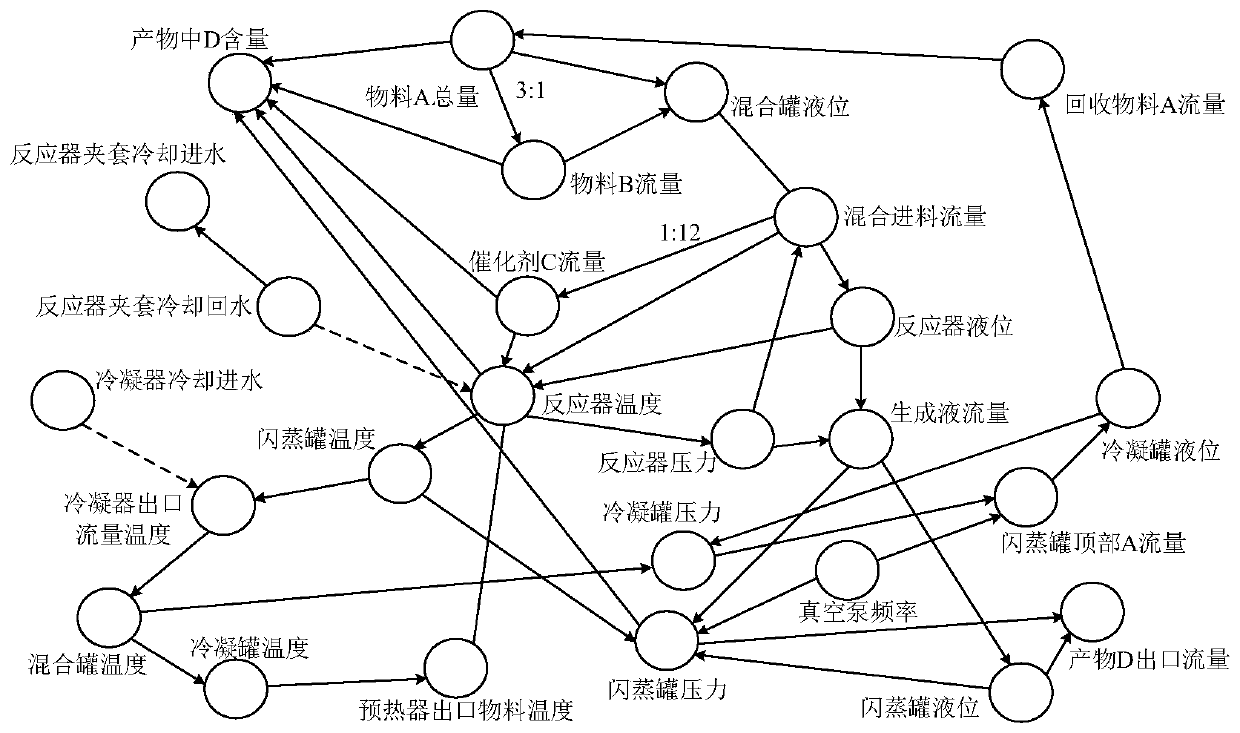

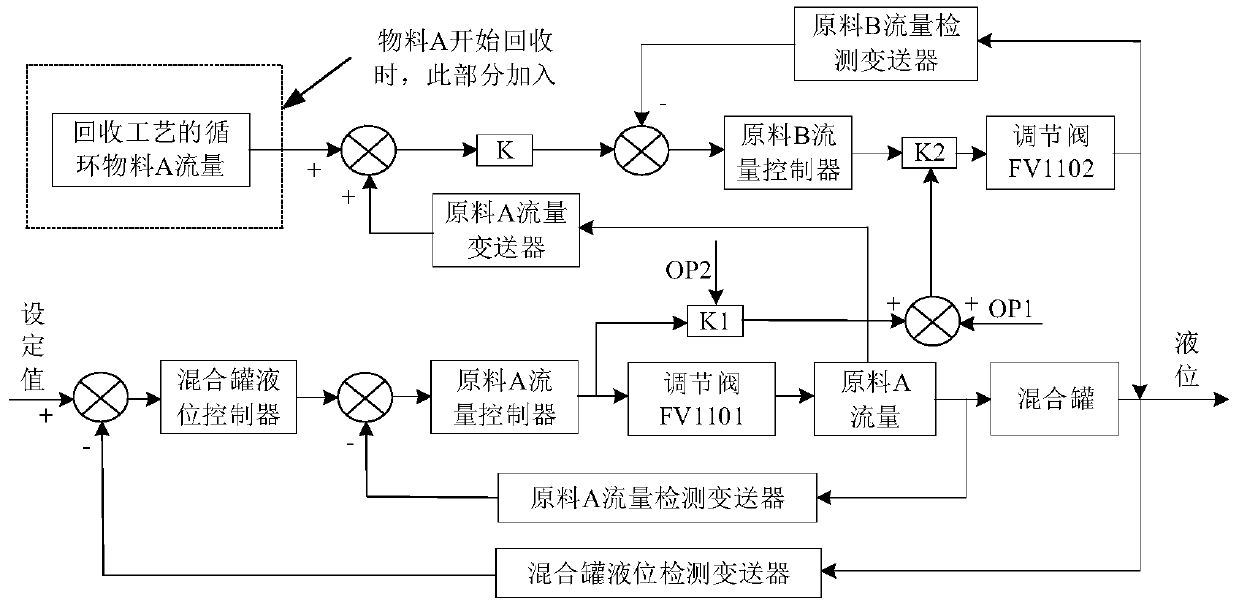

[0046] Such as figure 1 As shown, the controlled object is a common continuous process reaction system in the process industry, which can be divided into three parts: feeding preheating, exothermic reaction and separation and purification. Materials A and B are fully mixed and then reacted under the action of catalyst C. The main product D is generated, and the impurities are composed of by-product D and unproduced A, B, and C. Its reaction process is as follows figure 1 As shown, feed pump P101 for raw material A and feed pump P102 for raw material B add raw materials A and B to the mixing tank V101, mix well, heat through the preheater E101, enter the reactor, and act according to the following equation:

[0047] Main reaction: 2A+B—>D

[0048] Side reaction: A+B—>E

[0049] There is a catalyst C pipeline at the top of the reactor, and the delivery pump P103 feeds the catalyst into the reactor through the pipeline, and the exothermic reaction generates main product D and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com