Graphene oxide hybrid polyaniline-based flexible electrode material as well as preparation method and application thereof

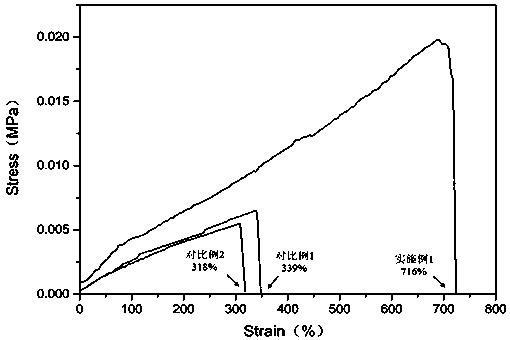

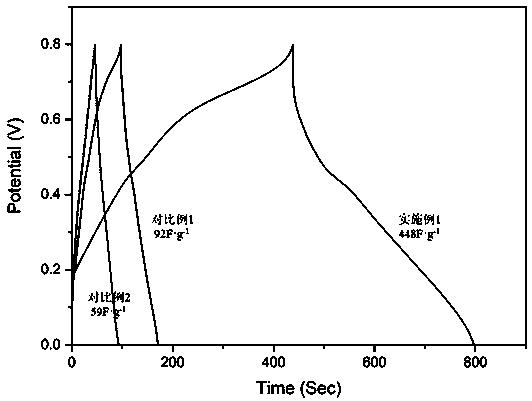

A polyaniline-based, flexible electrode technology, applied in the direction of hybrid capacitor electrodes, etc., can solve the problems of poor mechanical properties, easy rupture, low capacitance, etc., and achieve the effects of improved stability, improved mechanical properties, and enhanced electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Take 2 mL of deionized water and add 16 mg of graphene oxide powder, sonicate for 1 h to prepare a 0.8 wt% graphene oxide (GO) dispersion.

[0027] (2) Add 0.2 g of acrylamide to the GO dispersion in step (1), stir and dissolve until the liquid becomes clear; Ammonium sulfate solution, stirring and dissolving until the liquid is clear; pour the mixture into a 25mL small beaker, seal it, and polymerize at 90°C for 1 hour to obtain GMH.

[0028] (3) Put the GMH prepared in step (2) in 10ml of 2.6wt% aniline hydrochloride solution, store in a sealed environment at 0°C, and soak for 24 hours.

[0029] (4) Add 0.456g of ammonium persulfate and 200μl of 70wt% phytic acid into 2ml of deionized water and mix, cool to 0°C, and then quickly mix with the solution in step (3) to carry out polymerization reaction; after 24h, the product is washed with pure water After washing, the graphene oxide hybrid polyaniline-based flexible electrode material is obtained.

[0030] The ele...

Embodiment 2

[0044] (1) Take 2 mL of deionized water and add 6 mg of graphene oxide powder, sonicate for 1 h to prepare a 0.3 wt% graphene oxide (GO) dispersion.

[0045] (2) Add 0.2 g of acrylamide to the GO dispersion in step (1), stir and dissolve until the liquid becomes clear; Ammonium sulfate solution, stirring and dissolving until the liquid is clear; pour the mixture into a 25mL small beaker, seal it, and polymerize at 90°C for 1 hour to obtain GMH.

[0046] (3) Put the GMH prepared in step (2) in 10ml of 2.6wt% aniline hydrochloride solution, store in a sealed environment at 0°C, and soak for 24 hours.

[0047] (4) Add 0.456g of ammonium persulfate and 200μl of 70wt% phytic acid into 2ml of deionized water and mix, cool to 0°C, and then quickly mix with the solution in step (3) to carry out polymerization reaction; after 24h, the product is washed with pure water After washing, the graphene oxide hybrid polyaniline-based flexible electrode material is obtained.

[0048] The grap...

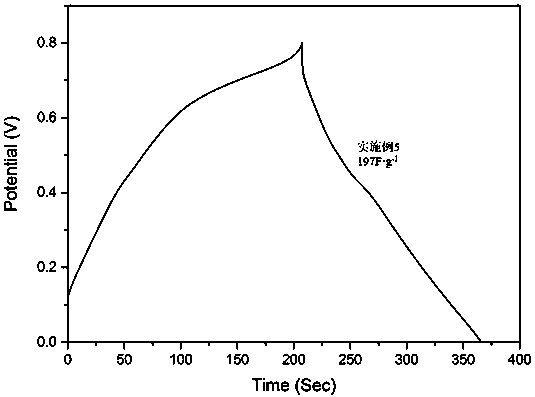

Embodiment 3

[0050] (1) Take 2 mL of deionized water and add 6 mg of graphene oxide powder, sonicate for 1 h to prepare a 0.3 wt% graphene oxide (GO) dispersion.

[0051] (2) Add 0.2 g of acrylamide to the GO dispersion in step (1), stir and dissolve until the liquid becomes clear; Ammonium sulfate solution, stirring and dissolving until the liquid is clear; pour the mixture into a 25mL small beaker, seal it, and polymerize at 90°C for 1 hour to obtain GMH.

[0052] (3) Put the GMH prepared in step (2) in 10ml of 2.6wt% aniline hydrochloride solution, store in a sealed environment at 0°C, and soak for 24 hours.

[0053] (4) Add 0.456g of ammonium persulfate and 200μl of 70wt% phytic acid into 2ml of deionized water and mix, cool to 0°C, and then quickly mix with the solution in step (3) to carry out polymerization reaction; after 24h, the product is washed with pure water After washing, the graphene oxide hybrid polyaniline-based flexible electrode material is obtained.

[0054] The grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Mass specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com