Nickel cobalt lithium manganate battery core positive electrode active material, aluminum housing battery core and manufacturing method thereof

A positive electrode active material, nickel-cobalt lithium manganese oxide technology, applied in the direction of active material electrodes, electrode carriers/collectors, positive electrodes, etc., can solve the problems of reducing the use value of lithium manganate, low ion transfer efficiency, and poor conductivity of the negative electrode , to achieve the effect of increased optional paths, good wettability, and sufficient contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

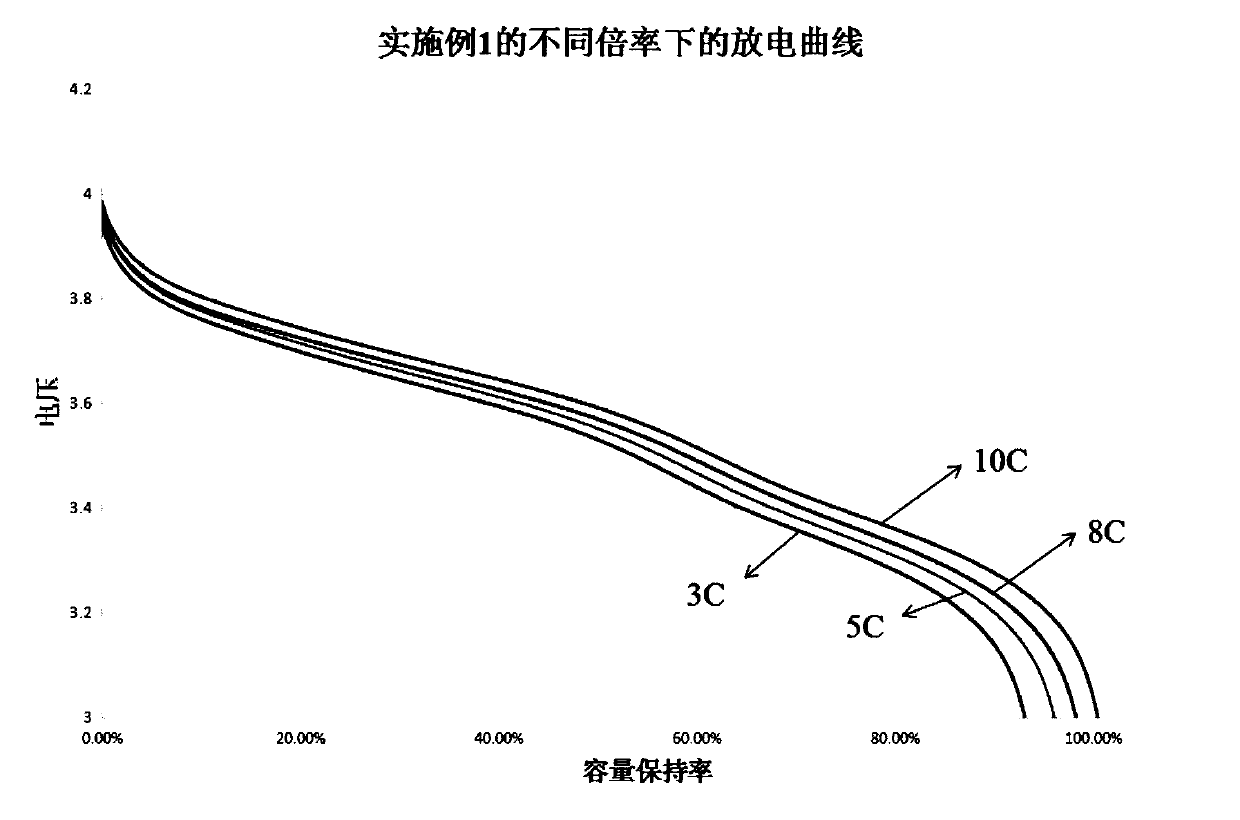

Embodiment 1

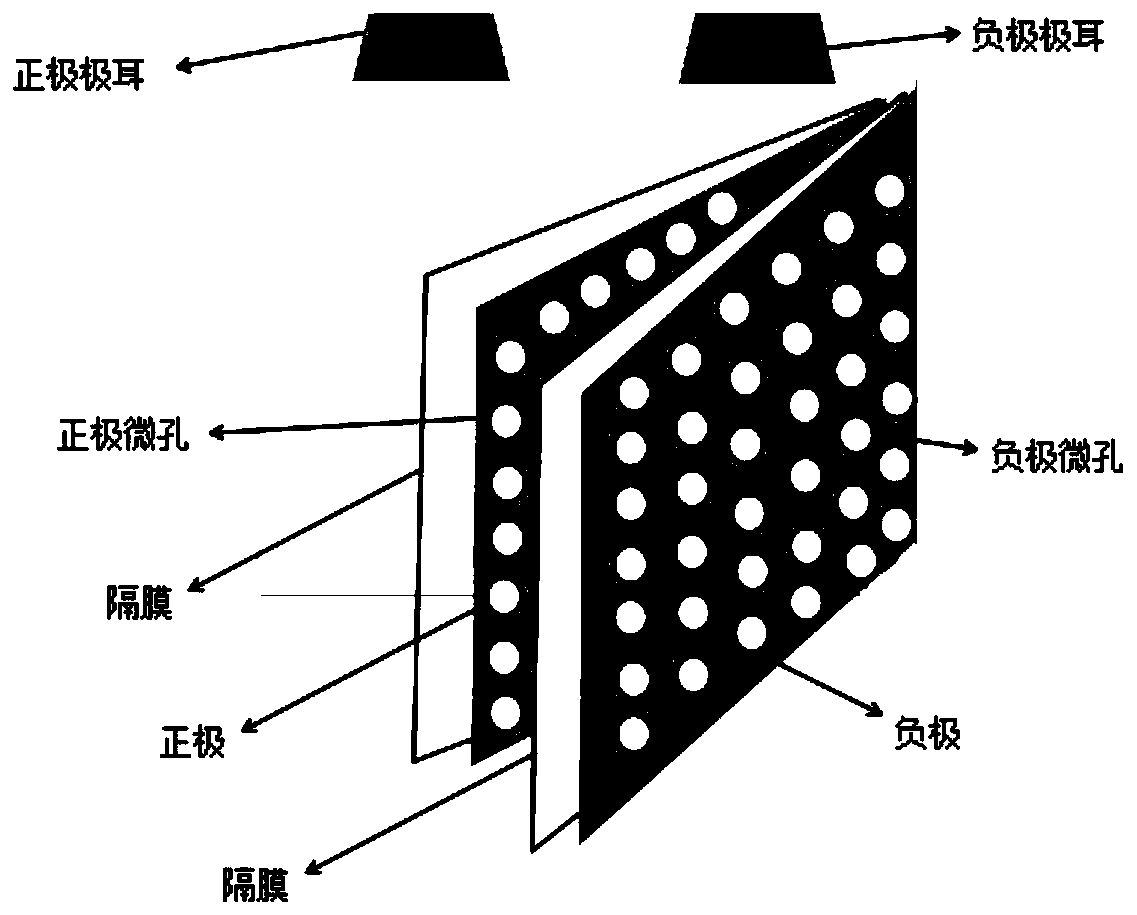

[0041] A lithium manganate and nickel-cobalt lithium manganese oxide aluminum-shell battery cell, comprising: a positive electrode, a negative electrode, a diaphragm, an electrolyte, and an aluminum shell shell, wherein:

[0042] The positive electrode is composed of a positive electrode active material, a binder, a conductive agent and a positive electrode current collector. The negative electrode is composed of a negative electrode active material, a conductive agent, a thickener, a binder and a negative electrode current collector. The positive electrode, negative electrode and separator form the battery cell. The battery core adopts a multi-pole winding structure in which the diaphragm, the positive electrode, the diaphragm, and the negative electrode are connected.

[0043] A kind of manufacturing method of lithium manganese oxide and nickel-cobalt lithium manganese oxide aluminum shell electric core, comprises the following steps:

[0044] (1) Ingredients: The positive...

Embodiment 2

[0055] A lithium manganate and nickel-cobalt lithium manganese oxide aluminum-shell battery cell, comprising: a positive electrode, a negative electrode, a diaphragm, an electrolyte, and an aluminum shell shell, wherein:

[0056] The positive electrode is composed of a positive electrode active material, a binder, a conductive agent and a positive electrode current collector. The negative electrode is composed of a negative electrode active material, a conductive agent, a thickener, a binder and a negative electrode current collector. The positive electrode, negative electrode and separator form the battery cell. The battery core adopts a multi-pole winding structure in which the diaphragm, the positive electrode, the diaphragm, and the negative electrode are connected.

[0057] A kind of manufacturing method of lithium manganese oxide and nickel cobalt lithium manganese oxide lithium aluminum shell electric core, comprises the following steps:

[0058] (1) Ingredients: The ...

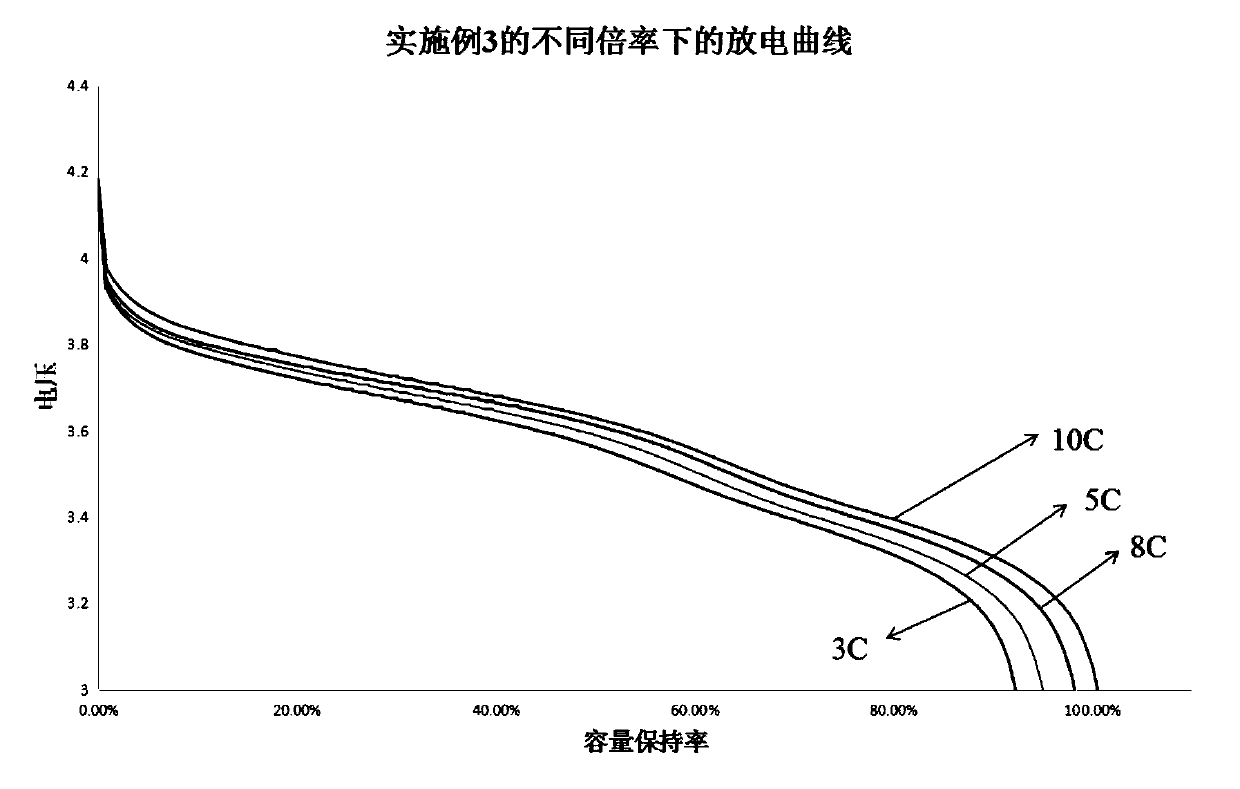

Embodiment 3

[0069] A lithium manganate and nickel-cobalt lithium manganese oxide aluminum-shell battery cell, comprising: a positive electrode, a negative electrode, a diaphragm, an electrolyte, and an aluminum shell shell, wherein:

[0070] The positive electrode is composed of a positive electrode active material, a binder, a conductive agent and a positive electrode current collector. The negative electrode is composed of a negative electrode active material, a conductive agent, a thickener, a binder and a negative electrode current collector. The positive electrode, negative electrode and separator form the battery cell. The battery core adopts a multi-pole winding structure in which the diaphragm, the positive electrode, the diaphragm, and the negative electrode are connected.

[0071] A kind of manufacturing method of lithium manganese oxide and nickel cobalt lithium manganese oxide lithium aluminum shell electric core, comprises the following steps:

[0072] (1) Ingredients: The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com