Flexible N/SnOx@ rGO composite material based on biological material substrate, preparation method and application thereof

A technology of composite materials and biomaterials, applied in the field of flexible N/SnOx@rGO composite materials and its preparation, can solve the problems of poor electrode stability, large volume change, poor conductivity, etc., and achieve strong crystallinity, simple process, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

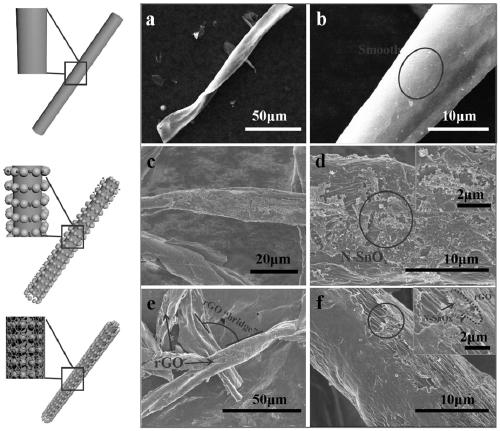

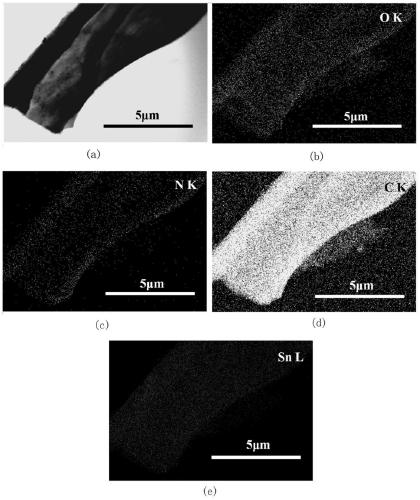

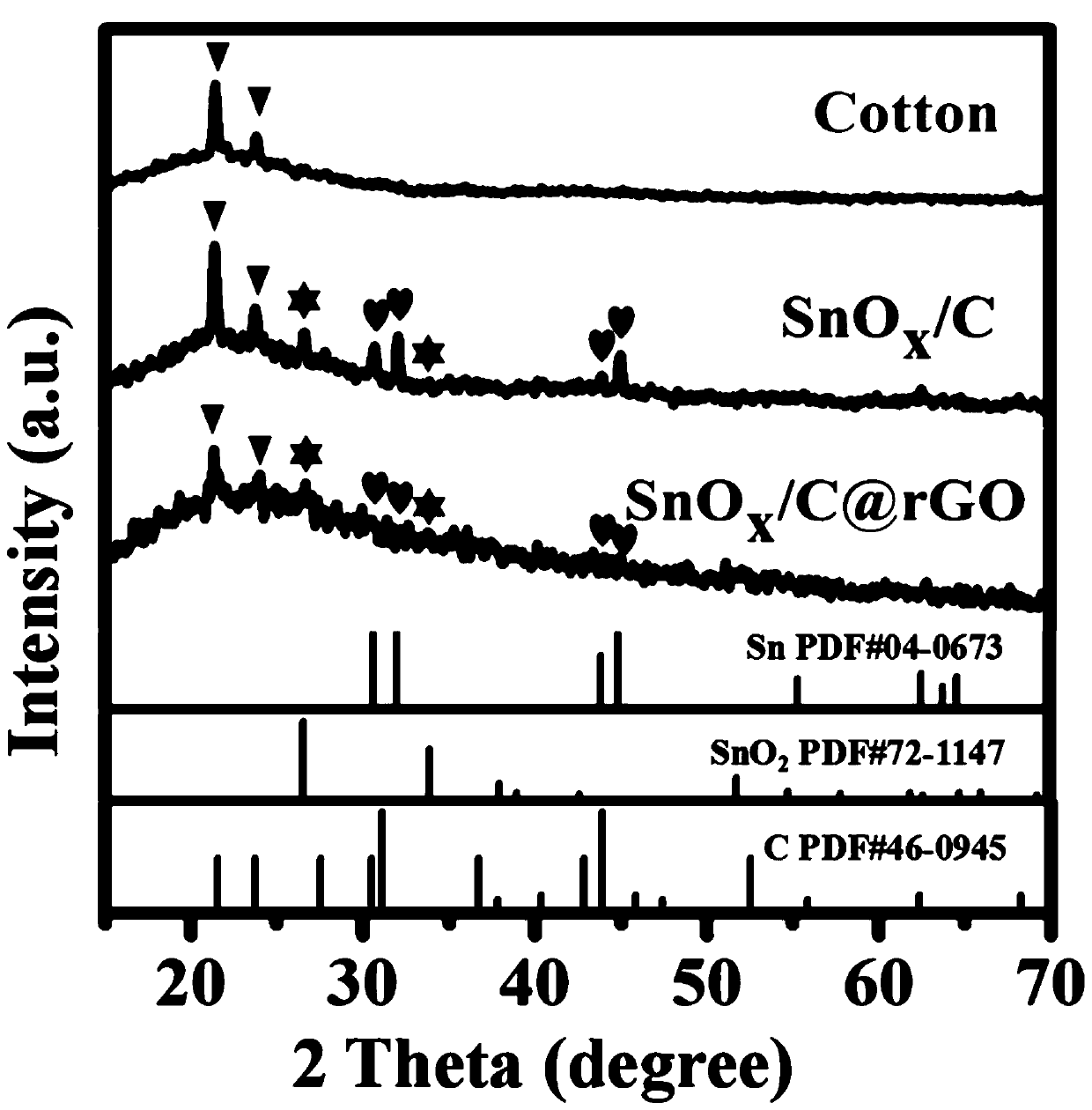

[0037] The invention provides a method for preparing a flexible N / SnOx@rGO composite material based on a biomaterial substrate, comprising the following steps:

[0038]S1, uncarbonized absorbent cotton substrate SnO x Preparation of nanostructures;

[0039] The absorbent cotton was pretreated, the medical absorbent cotton was peeled off and cut into 3cm×3cm×0.1cm cubes, washed alternately with deionized water and ethanol three times, and dried at 30°C to obtain absorbent cotton A; then, SnCl 4 ·5H 2 O and deionized water were mixed according to the ratio of (0.5-2.0) g: (50-100) mL, and after stirring for 1 hour, solution B was obtained; solution B was mixed with 6 mL of 25% ammonia water to obtain solution C; absorbent cotton A Put it into solution C for mixing and ultrasonic treatment for 1 to 3 hours to obtain absorbent cotton D, that is, non-carbonized absorbent cotton substrate SnO x Nano-structure;

[0040] S2, flexible carbon substrate N / SnO x Preparation of nanost...

Embodiment 1

[0053] S1, uncarbonized absorbent cotton substrate SnO x Preparation of nanostructures:

[0054] First, pretreat the absorbent cotton, peel off the medical absorbent cotton and cut it into a cube of 3cm×3cm×0.1cm, wash it alternately with deionized water and ethanol three times, and dry it at 30°C to obtain absorbent cotton A; then, 0.6g SnCl 4 ·5H 2 O and 60ml of deionized water were mixed, stirred for 1 hour to obtain solution B; solution B was mixed with 6ml of 25% ammonia water to obtain solution C; absorbent cotton A was put into solution C for mixing and then ultrasonically treated for 1 hour to obtain absorbent cotton d. That is, uncarbonized absorbent cotton substrate SnO x Nano-structure.

[0055] S2, flexible carbon substrate N / SnO x Preparation of nanostructures:

[0056] Absorbent cotton D was freeze-dried to obtain absorbent cotton E; finally, absorbent cotton E was carbonized in a tube furnace at 700°C for 5 hours, and 200 sccm of N 2 Obtain carbonized ab...

Embodiment 2

[0063] S1, uncarbonized absorbent cotton substrate SnO x Preparation of nanostructures:

[0064] First, pretreat the absorbent cotton, peel off the medical absorbent cotton and cut it into a cube of 3cm×3cm×0.1cm, wash it alternately with deionized water and ethanol three times, and dry it at 30°C to obtain absorbent cotton A; then, 0.8g SnCl 4 ·5H 2 O and 60mL deionized water were mixed, stirred for 1 hour to obtain solution B; solution B was mixed with 6mL 25% ammonia water to obtain solution C; absorbent cotton A was put into solution C for mixing and then ultrasonically treated for 1 hour to obtain absorbent cotton d. That is, uncarbonized absorbent cotton substrate SnO x Nano-structure.

[0065] S2, flexible carbon substrate N / SnO x Preparation of nanostructures:

[0066] Absorbent cotton D was freeze-dried to obtain absorbent cotton E; finally, absorbent cotton E was carbonized in a tube furnace at 700°C for 5 hours, and 200 sccm of N 2 Obtain carbonized absorben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com