A kind of niti nano flower hydrotalcite photocatalyst and its preparation method and application

A technology of catalysts and nanoflowers, which is applied in the field of NiTi hydrotalcite photocatalysts and its preparation, can solve problems such as unfavorable applications and limited reaction conditions, achieve simple preparation methods, low requirements for reaction conditions, and improve apparent quantum efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of nickel-titanium nano flower hydrotalcite photocatalyst, comprising the steps of:

[0038] (1) Dissolve 0.29g of nickel nitrate hexahydrate, 0.237g of titanium sulfate and 2.8g of urotropine into 50 mL of deionized water, stir well to obtain a transparent solution;

[0039] (2) Transfer the transparent solution described in step (1) to a polytetrafluoroethylene lining and heat up in a muffle furnace for a heating reaction. The temperature of the heating reaction is 140°C, and the heating reaction time is 9 hours. Cool to room temperature. The heated product was obtained, and the precipitate was collected by suction filtration;

[0040] (3) drying the precipitate in step (2) at 30° C. to obtain the nickel-titanium nanoflower hydrotalcite photocatalyst.

Embodiment 2

[0042] A preparation method of nickel-titanium nano flower hydrotalcite photocatalyst, comprising the steps of:

[0043] (1) Dissolve 0.8721g of nickel nitrate hexahydrate, 0.237g of titanium sulfate and 2.8g of urotropine into 50 mL of deionized water, stir well to obtain a transparent solution;

[0044] (2) Transfer the transparent solution described in step (1) to a polytetrafluoroethylene lining and heat up in a muffle furnace for a heating reaction. The temperature of the heating reaction is 140°C, and the heating reaction time is 9 hours. Cool to room temperature. The heated product was obtained, and the precipitate was collected by suction filtration;

[0045] (3) drying the precipitate in step (2) at 60° C. to obtain the nickel-titanium nanoflower hydrotalcite photocatalyst.

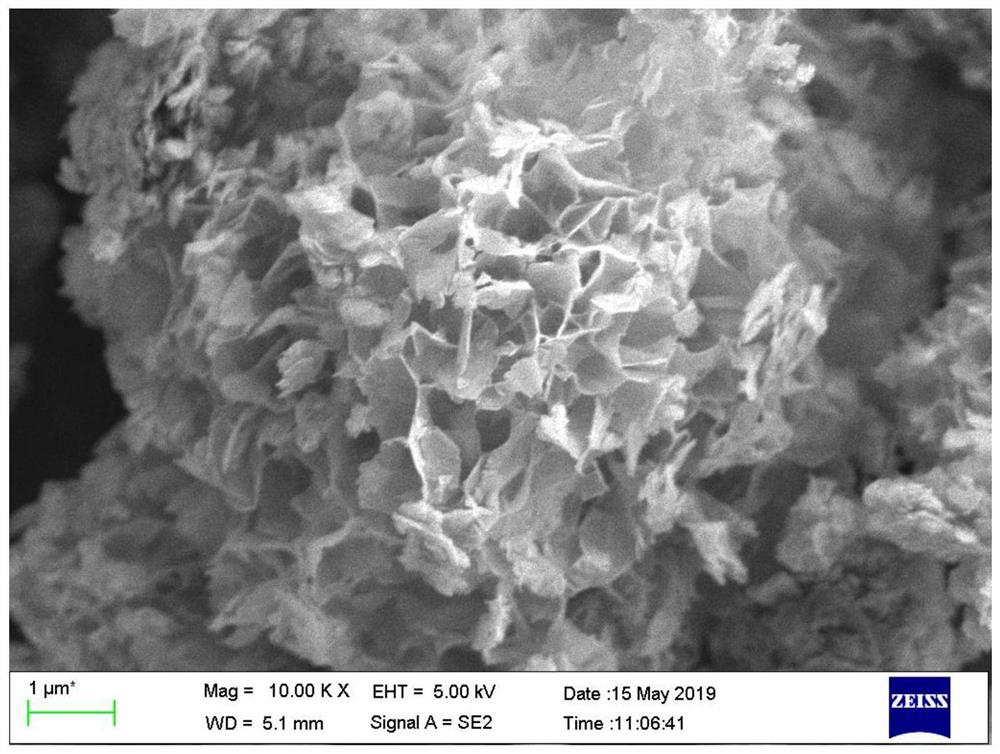

[0046] The effect that the nickel-titanium nano-flower hydrotalcite photocatalyst that embodiment 2 makes is observed under the scanning electron microscope is as follows: figure 1 shown, from ...

Embodiment 3

[0048] A preparation method of nickel-titanium nano flower hydrotalcite photocatalyst, comprising the steps of:

[0049] (1) Dissolve 1.45g of nickel nitrate hexahydrate, 0.237g of titanium sulfate and 2.8g of urotropine into 50 mL of deionized water, stir well to obtain a transparent solution;

[0050] (2) Transfer the transparent solution described in step (1) to a polytetrafluoroethylene lining and heat up in a muffle furnace for a heating reaction. The temperature of the heating reaction is 140°C, and the heating reaction time is 9 hours. Cool to room temperature. The heated product was obtained, and the precipitate was collected by suction filtration;

[0051] (3) drying the precipitate in step (2) at 100° C. to obtain the nickel-titanium nanoflower hydrotalcite photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com