A kind of solid waste-based ceramic catalytic membrane and its preparation method and application

A catalytic membrane and ceramic technology, applied in the field of catalytic material preparation, can solve problems such as difficulty in recycling, and achieve the effects of relieving pressure, low sintering temperature and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

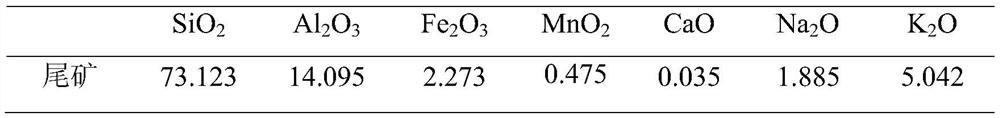

[0041] Table 1 is the main element composition (%) of several classes of raw materials

[0042]

[0043]

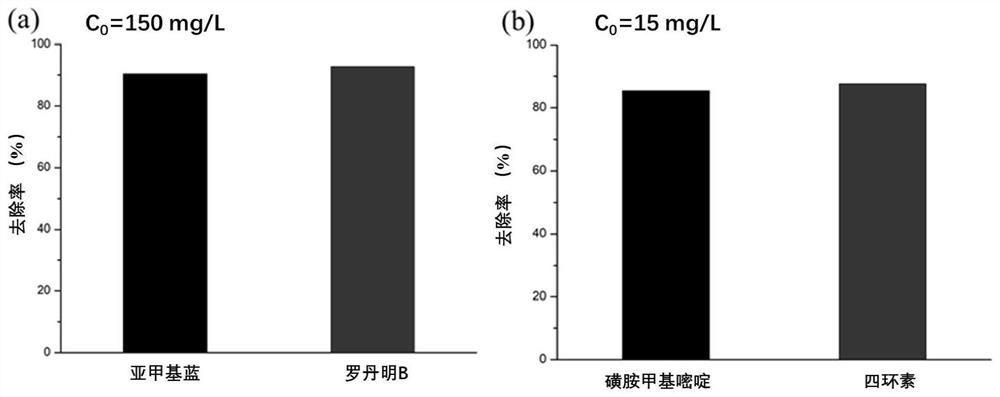

[0044] Table 2 is the wastewater from a dye factory in Ningxiang, Hunan. The wastewater from this dye factory contains a large amount of Rhodamine B. The water quality is shown in Table 2 (mg / L, except pH)

[0045]

[0046] Preparation of solid waste-based ceramic catalytic membrane: Weigh 65g of silicate tailings, 15g of bauxite and 20g of manganese slag, put them into a ball mill jar and wet grind at 350rpm for 10h, and dry the obtained slurry at 60°C for 7h. The powder passed through a 300-mesh sieve, weighed, put 2g of the sieved powder into a circular mold, and molded at 5MPa; after sintering at 550°C for 2h, then sintering at 1130°C for 30min, and took out the sample after cooling in the furnace. The prepared ceramic membrane was characterized, and the compressive strength was 11.6MPa, the porosity was 51.4%, and the average pore size was 550nm.

[0047] A...

Embodiment 2

[0049] Table 3 is the main element composition (%) of several classes of raw materials

[0050]

[0051] Table 4 is the wastewater of a certain pharmaceutical factory in Zhuzhou, Hunan. The water quality is as shown in Table 4 (mg / L, except pH)

[0052]

[0053] Preparation of solid waste-based ceramic catalytic membrane: Weigh 65g of silicate tailings, 15g of bauxite and 20g of red mud, put them into a ball mill tank and wet grind at 300rpm for 12h, and dry the obtained slurry at 65°C for 8h. The powder passed through a 320-mesh sieve, weighed, put 2g of the under-sieved powder into a circular mold at 8MPa, and molded at 550°C for 2h, then sintered at 1140°C for 20min, and took out the sample after cooling in the furnace. The prepared ceramic membrane was characterized, and the compressive strength was 13.1MPa, the porosity was 48.5%, and the average pore size was 517nm. The application of solid waste-based ceramic catalytic membrane: the prepared catalytic membrane is...

Embodiment 3

[0055] Table 5 is the main element composition (%) of several classes of raw materials

[0056]

[0057] Table 6 is the percentage composition (%) of each raw material in different formulas:

[0058]

[0059] Table 7 shows the wastewater from a printing and dyeing factory in Xiangtan, Hunan. The water quality is shown in Table 7 (mg / L, except for pH)

[0060]

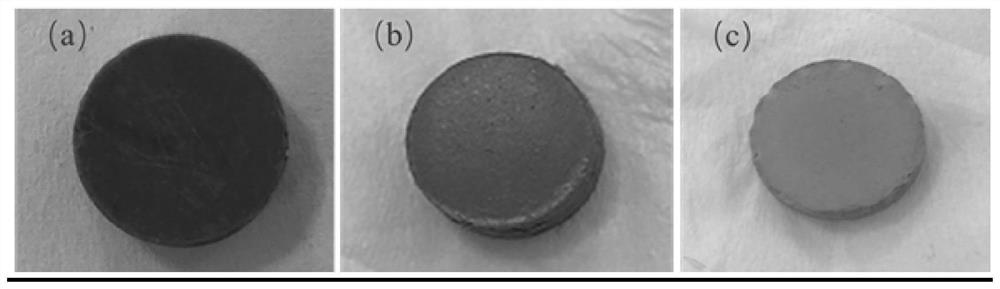

[0061] Preparation of solid waste-based ceramic catalytic membrane: Weigh each raw material according to 4 formulas, put them into a ball mill jar and wet mill at 320rpm for 10h, dry the obtained slurry at 65°C for 8h, and pass the dried powder through a 320-mesh sieve , respectively weighed 2g of the under-sieve powder and put them into a circular mold at 7MPa to form; sintered at 550°C for 100min, then sintered at 1130°C for 30min, took out the samples after cooling in the furnace, and recorded them as sample 1 and sample 2 respectively. , Sample 3 and Sample 4. The prepared ceramic membranes were character...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com