Preparation method of ZIF-8/enzyme composite material

A technology of ZIF-8 and composite materials, applied in the direction of fixing on/in the organic carrier, fixing on or in the inorganic carrier, etc., can solve the problems of restricting the diffusion of large-size substrates and hindering the application, and achieve excellent Catalytic ability, low price, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

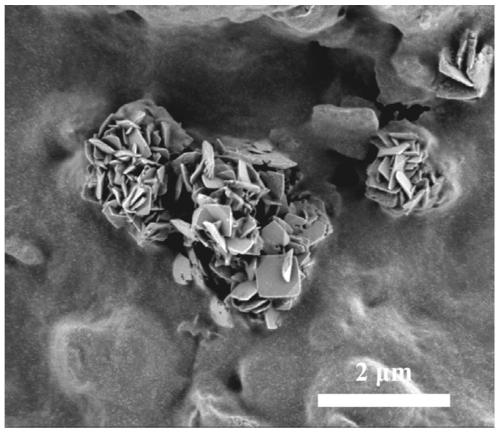

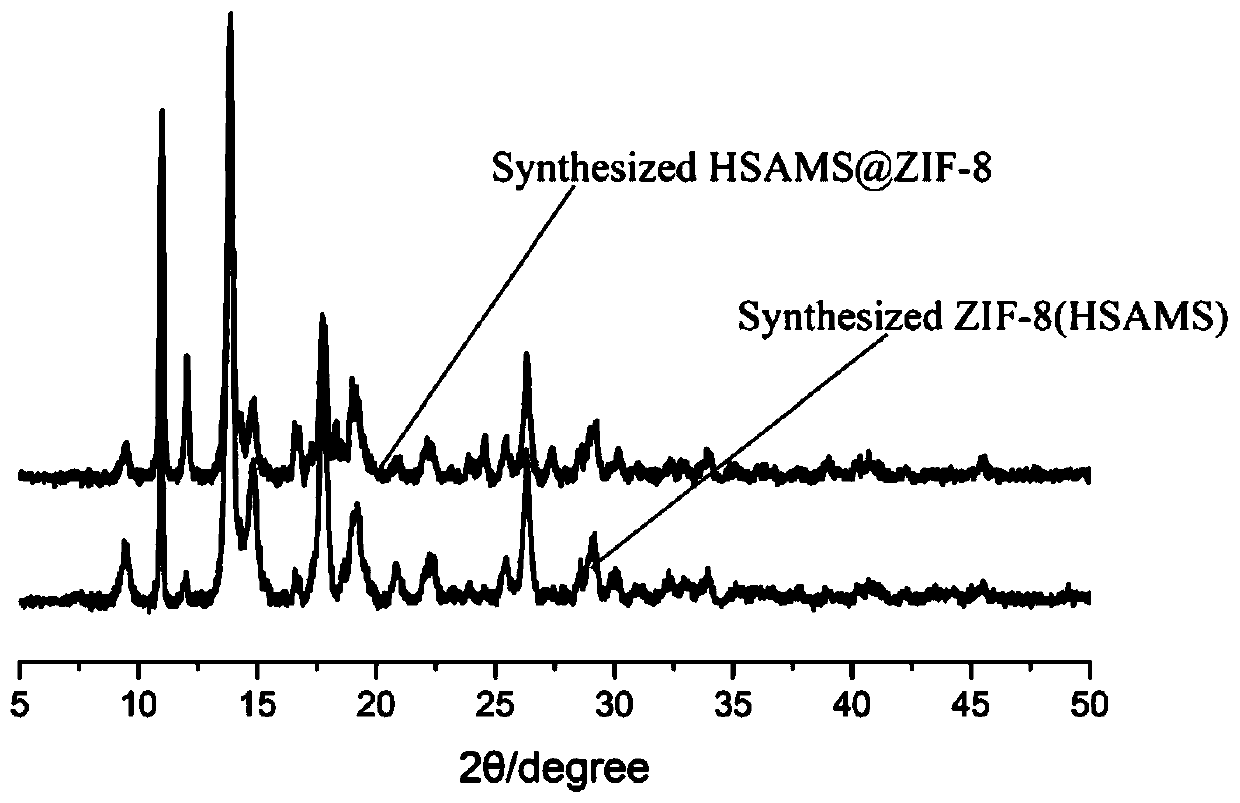

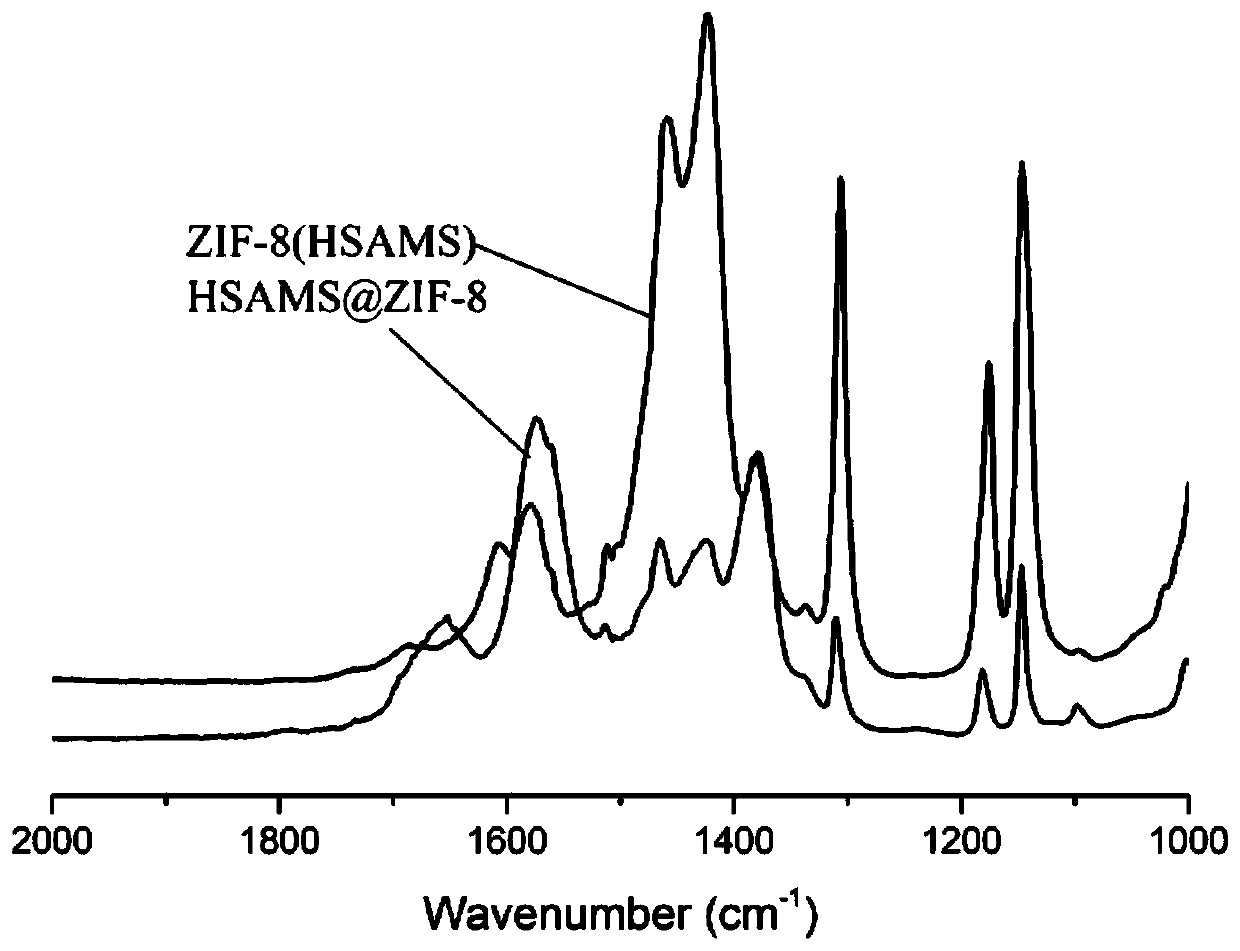

[0036] Screen and optimize the conditions for the preparation of HSAMS@ZIF-8. Its method steps are:

[0037] (1) Dissolve 0.65 mg, 1.3 mg, 1.9 mg, 2.5 mg, 5 mg, and 10 mg of zinc nitrate hexahydrate in 420 μL of water, respectively, to obtain zinc nitrate solutions 1, 2, 3, 4, 5, and 6;

[0038] (2) Dissolve 0.7mg, 1.4mg, 2.1mg, 2.8mg, 5.5mg, and 11mg of 2-methylimidazole in 420μL of water, respectively, and then add 20μL of HSAMS (concentration: 6mg / mL), and stir for 5min to obtain 2 - Methylimidazole / enzyme solutions 1, 2, 3, 4, 5, 6;

[0039] (3) Mix the 2-methylimidazole / enzyme solutions 1, 2, 3, 4, 5, and 6 with the corresponding zinc nitrate solutions, stir at room temperature for 4 hours, then centrifuge (10000rpm, 5min), and use a concentration of 0.1mol / L, Tris-HCl buffer solution with pH=8.0 washed the solid 3 times to obtain HSAMS@ZIF-8 samples 1, 2, 3, 4, 5, 6;

[0040] (4) Prepare the HSAMS reaction substrate mixed solution, numbered as solution a. The prepar...

Embodiment 2

[0044] It was proved that HSAMS@ZIF-8 has good catalytic ability, and the reactivity of HSAMS@ZIF-8 was compared with that of free HSAMS. Its method steps are:

[0045] (1) Dissolve 1.3 mg of zinc nitrate hexahydrate in 420 μL of water to obtain a zinc nitrate solution;

[0046] (2) Dissolve 1.4 mg of 2-methylimidazole in 420 μL of water, then add 20 μL of HSAMS (concentration: 6 mg / mL), and stir for 5 minutes to obtain 2-methylimidazole / enzyme solution;

[0047] (3) Mix the 2-methylimidazole / enzyme solution with the zinc nitrate solution, stir at room temperature for 4h, centrifuge (10000rpm, 5min), and wash the solid with Tris-HCl buffer solution with a concentration of 0.1mol / L and pH=8.0 3 times, get HSAMS@ZIF-8;

[0048] (4) Add 20 μL of solution a to HSAMS@ZIF-8, 180 μL of Tris-HCl buffer with a concentration of 0.1mol / L and pH=8.0; add 20 μL of solution a to 20 μL of HSAMS (concentration of 6 mg / mL), 160 μL of 0.1mol / L, Tris-HCl buffer solution with pH=8.0. The two we...

Embodiment 3

[0050] It was proved that HSAMS@ZIF-8 has better reaction stability than free HSAMS, and the reactivity of HSAMS@ZIF-8 and free HSAMS was compared under the conditions of high temperature, organic solvent and trypsin solution. Its method steps are:

[0051] (1) Prepare 5 copies of HSAMS@ZIF-8, numbered a1, a2, a3, a4, a5 respectively. For the experimental operation method, refer to the steps (1) (2) (3) of Example 2. Take 5 copies of 20μL HSAMS (concentration: 6mg / mL), numbered b1, b2, b3, b4, b5 respectively;

[0052] (2) Add 20 μL solution a, 80 μL Tris-HCl buffer solution with a concentration of 0.1 mol / L, pH=8.0, and 100 μL methanol to a1; add 20 μL solution a, 30 μL concentration of 0.1 mol / L, pH= 8.0 Tris-HCl buffer solution, 150 μL dimethylsulfoxide (DMSO); add 20 μL solution a to a3, 180 μL Tris-HCl buffer solution with a concentration of 0.1mol / L, pH=8.0, 0.01 mg trypsin ; Add 20 μL of solution a, 180 μL of Tris-HCl buffer solution with a concentration of 0.1 mol / L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com