Magnesium-silicon-iron alloy spheroidizing agent and preparation method thereof

A ferroalloy and nodulizer technology, applied in the field of alloy metal materials, can solve the problems of subcutaneous stoma defects and high cost, and achieve the effects of reducing production cost, reducing environmental burden and low aluminum content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

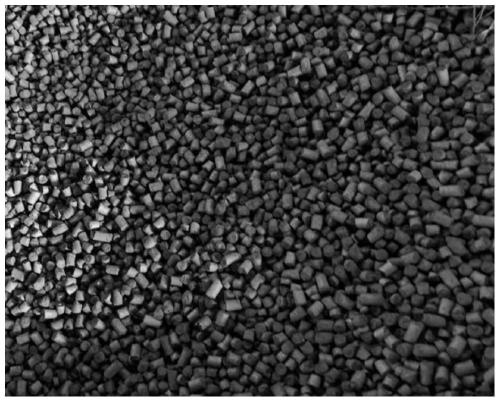

Image

Examples

preparation example Construction

[0022] The preparation method of the magnesium ferrosilicon alloy spheroidizing agent provided by the present invention includes the following steps:

[0023] (1) Dry the monocrystalline silicon cutting material or polycrystalline silicon cutting material;

[0024] (2) Mix 40-50 parts by weight of the dried monocrystalline silicon cutting material or polycrystalline silicon cutting material with 45-55 parts by weight of scrap steel, and then use an induction furnace for smelting to obtain an alloy liquid;

[0025] (3) 5-9 parts by weight of metallic magnesium, 2-5 parts by weight of metallic calcium and 1-3 parts by weight of lanthanum-cerium rare earth are added to the alloy liquid, and the alloying reaction is carried out at 1250-1300°C, and then Pouring and molding are carried out to obtain a magnesium ferrosilicon alloy spheroidizing agent.

[0026] From the above description, the beneficial effects of the present invention are:

[0027] Through the design of the above preparation ...

Embodiment 1

[0038] The preparation method of the magnesium ferrosilicon alloy spheroidizing agent of this embodiment includes the following steps:

[0039] The high-purity water-containing silicon powder scraps produced during the slicing process of solar-grade single / polycrystalline silicon plates are used as raw materials, which are extruded and pelletized in an extruder. The pellets are put into a rotary drying kiln and dried at 80°C. 1mm or more of the pellets account for more than 85%. The weighed mono / polycrystalline silicon chip cutting powder pellets and clean scrap are heated and melted in the induction furnace. After the materials are melted, the power is cut off and the slag is removed. The molten pool The temperature is controlled at 1250℃, the power is turned on, and the semi-hermetic gravity pressure magnesium process is adopted to quickly press the metal magnesium, metal calcium and lanthanum cerium rare earth into the alloy liquid for alloying reaction. After the reaction is c...

Embodiment 2

[0042] The preparation method of the magnesium ferrosilicon alloy spheroidizing agent of this embodiment includes the following steps:

[0043] The high-purity water-containing silicon powder scraps produced during the slicing process of solar-grade single / polycrystalline silicon plates are used as raw materials, which are extruded and pelletized in an extruder. The pellets are put into a rotary drying kiln and dried at 150°C. 1mm or more of the pellets account for more than 85%. The weighed mono / polycrystalline silicon chip cutting powder pellets and clean scrap are heated and melted in the induction furnace. After the materials are melted, the power is cut off and the slag is removed. The molten pool The temperature is controlled at 1300℃, the power is turned on, and the semi-hermetic gravity pressure magnesium process is adopted to quickly press the metallic magnesium, metallic calcium and lanthanum-cerium rare earth into the alloy liquid for alloying reaction. After the reacti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com