Preparation method of polyaluminium sulfate zinc composite flocculant

A composite flocculant, polyaluminum sulfate technology, applied in the field of environment and chemistry, can solve problems such as aluminum poisoning symptoms, toxic effects, and aluminum harm to human body, and achieve the effects of less dosage, long shelf life and fast settling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

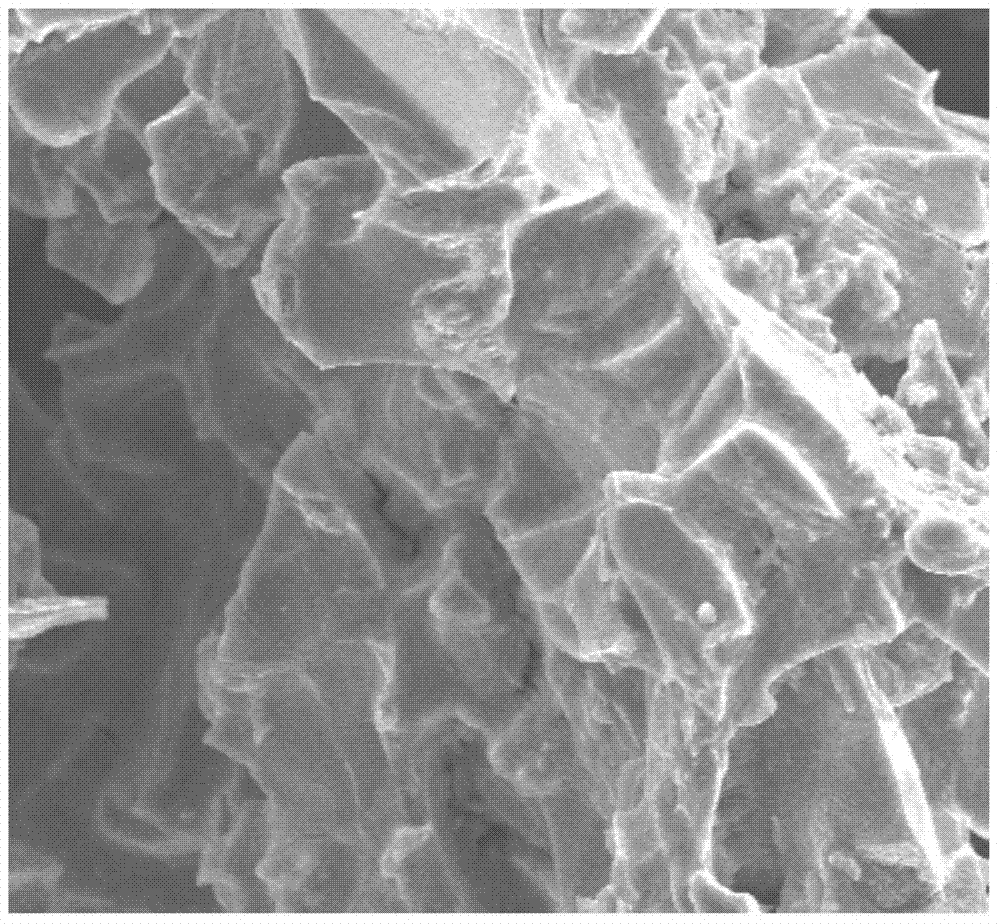

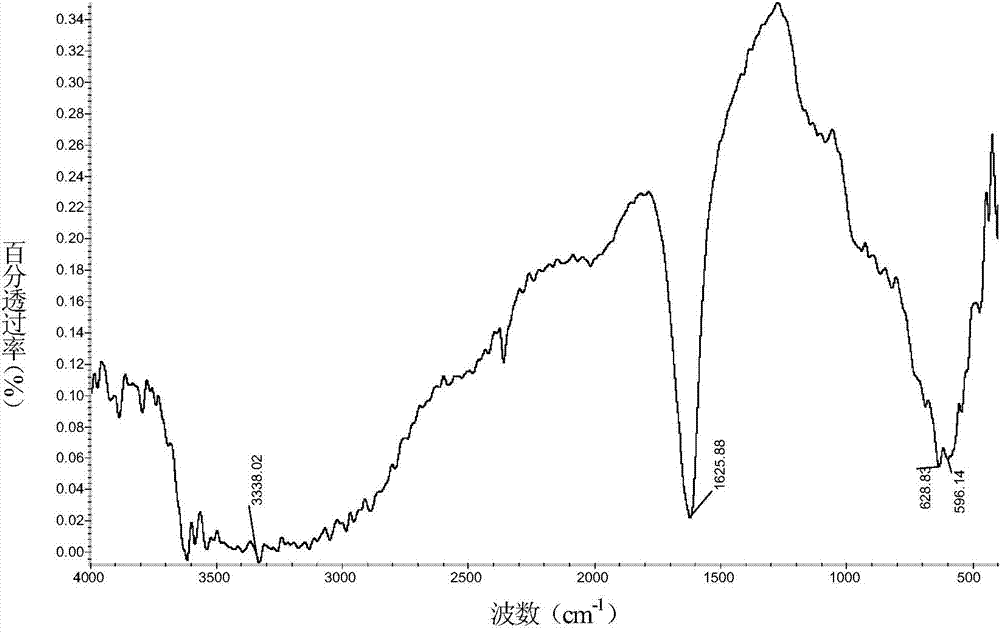

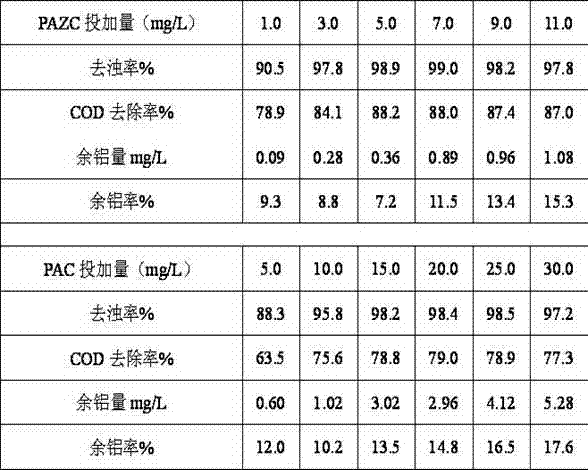

Image

Examples

Embodiment 1

[0019] At room temperature, mix 40 parts of zinc sulfate aqueous solution with a mass percentage concentration of 0.5% and 60 parts of aluminum sulfate aqueous solution with a mass percentage concentration of 10%, and add 15 parts of a 50% sodium hydroxide aqueous solution dropwise on a magnetic heating stirrer. , stirred for 30 min, and stood still for 0.5 h to obtain a clear polyaluminum chloride zinc composite flocculant, which was dried at 50°C to produce a semi-crystalline white solid, that is, a polyaluminum zinc sulfate composite flocculant.

Embodiment 2

[0021] At room temperature, 50 parts of zinc sulfate aqueous solution with a concentration of 1% by mass and 60 parts of aqueous aluminum sulfate with a concentration of 15% by mass were mixed, and 25 parts of aqueous sodium hydroxide solution with a concentration of 50% were added dropwise on a magnetic heating stirrer. , stirred for 30 min, and stood still for 2.0 h to obtain a clear and transparent polyaluminum-zinc sulfate composite flocculant, which was dried at 50°C to produce a semi-crystalline white solid, that is, a polyaluminum-zinc sulfate composite flocculant.

Embodiment 3

[0023] At room temperature, 40 parts of zinc sulfate aqueous solution with a concentration of 0.75% by mass and 50 parts of aqueous aluminum sulfate with a concentration of 10% by mass were mixed, and 40 parts of aqueous potassium hydroxide with a concentration of 50% were added dropwise on a magnetic heating stirrer. , stirred for 30 min, and stood still for 6.0 h to obtain a clear and transparent polyaluminum-zinc sulfate composite flocculant, which was dried at 50°C to produce a semi-crystalline white solid, that is, a polyaluminum-zinc sulfate composite flocculant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com