An electron beam divergence angle measuring device and its preparation method and measurement method

A measuring device and electron beam technology, applied in measuring devices, radiation measurement, X/γ/cosmic radiation measurement, etc., can solve the extremely high collimation requirements of the experimental device, which is not suitable for the measurement of the divergence angle of the electron beam, and is difficult to measure On-site development and other issues to achieve the effect of easy control, high precision and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

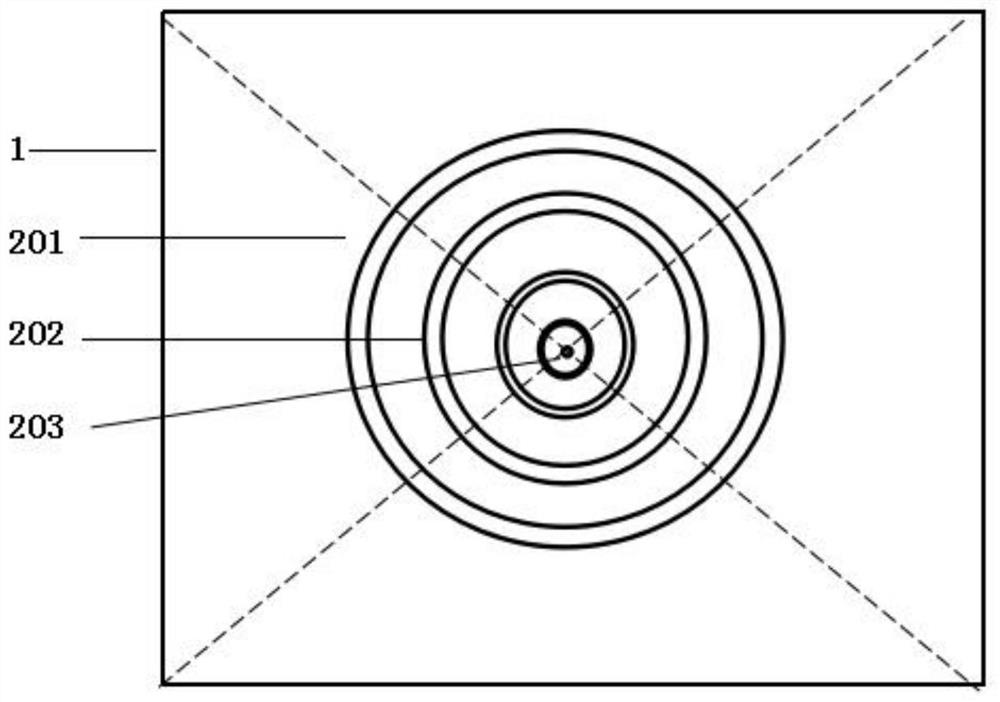

[0026] like Figure 1-2 , The present embodiment provides an electron beam divergence angle measuring means, the measuring device applied to a reflection high energy electron diffraction apparatus comprising a screen and a micro-nano tungsten pattern 201, a conventional phosphor screen the phosphor screen 1, a square shape, while length 20mm ,; thickness of 1mm. Tungsten micro-nano pattern 201 as a plurality of concentric circles, concentric circles of 10 m minimum radius, maximum radius of 150 m, 10 m radius interval, wherein the concentric circles deposited from tungsten hexacarbonyl tungsten wire 202 is formed, the shape of the tungsten wire of 202 cylindrical with a diameter of 50nm.

[0027] Measuring device for preparing reflection high energy electron diffraction divergence angle of the electron beam, comprising the steps of:

[0028] 1, the cleaning surface of the faceplate 1: 1 on the screen inside a helium ion microscope to be vacuum evacuated to 10 -3 When Pa or less, us...

Embodiment 2

[0033] An electron beam measuring device in the present embodiment the divergence angle, such as figure 1 , The phosphor screen including a micro-nano pattern 201 and tungsten. 1 is a conventional phosphor screen the phosphor screen, the shape of a square with a side length of 20-30mm; thickness of 3mm. Tungsten micro-nano pattern 201 are concentric, the minimum radius of 10 m, the maximum radius of 150 m, an interval of 20 m radius, wherein tungsten hexacarbonyl, tungsten deposited from line 202, is cylindrical in shape, having a diameter of 150nm.

[0034] Measuring device for preparing reflection high energy electron diffraction divergence angle of the electron beam, comprising the steps of:

[0035] 1, the cleaning surface of the faceplate 1: 1 on the screen inside a helium ion microscope to be vacuum evacuated to 10 -3 When Pa or less, using ions washed for 5 minutes to remove surface oxides and contaminants a phosphor screen;

[0036] 2, tungsten micro-nano pattern 201 Prepa...

Embodiment 3

[0038] Electron beam divergence angle of the measuring device of the present embodiment, as figure 1 , The phosphor screen including a micro-nano pattern 201 and tungsten. 1 is a conventional phosphor screen the phosphor screen, the shape of a square with a side length of 25mm; thickness of 2mm. Tungsten micro-nano pattern 201 are concentric, the minimum radius of 10 m, the maximum radius of 150 m, 15 m radius interval, wherein tungsten hexacarbonyl, tungsten deposited from line 202, is cylindrical in shape, having a diameter of 100nm.

[0039] Measuring device for preparing reflection high energy electron diffraction divergence angle of the electron beam, comprising the steps of:

[0040] 1, the cleaning surface of the faceplate 1: 1 on the screen inside a helium ion microscope to be vacuum evacuated to 10 -3 When Pa or less, using ions washed four minutes to remove surface oxides and contaminants a phosphor screen;

[0041] 2, tungsten micro-nano pattern 201 Preparation: After th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com