Separation extracting device and method for micro plastic in soil

An extraction device and a technology for microplastics, applied in liquid cleaning methods, solid separation, wet separation, etc., can solve the problems of microplastics separation and extraction, identification and analysis, less research and difficulties, so as to save manpower and improve recovery Efficiency, the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

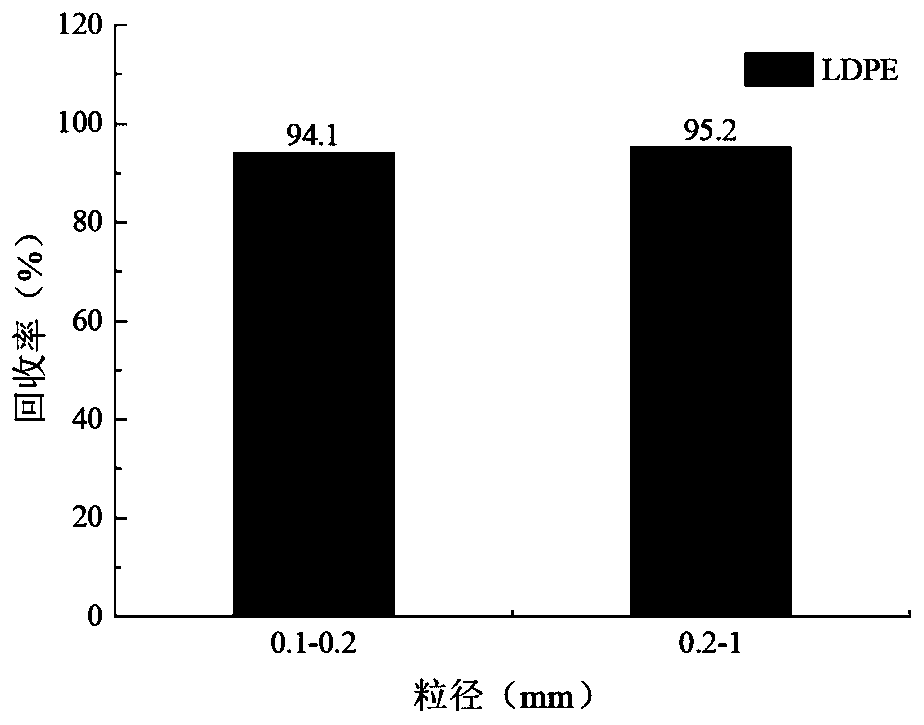

Embodiment 1

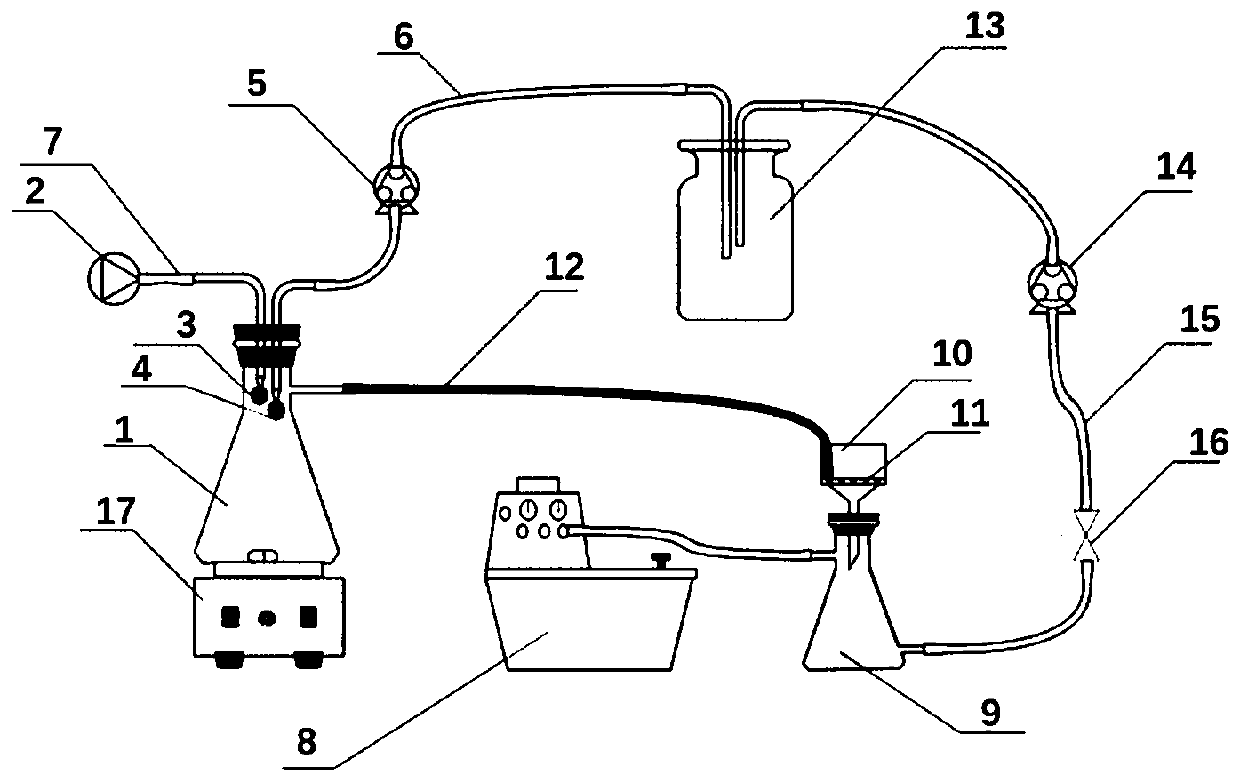

[0045] Such as figure 1 As shown, a separation and extraction device for microplastics in soil, including a separation system and a filtration system, is characterized in that a liquid inlet pipe 6 is set between the liquid storage tank 13 and the separation pool 1, and the upper and lower nozzle suction filter bottles 9 are connected to the A liquid outlet pipe 15 is arranged between the liquid storage tanks 13, a peristaltic pump I5 and a peristaltic pump II14 are arranged on the liquid inlet pipe 6 and the liquid outlet pipe 15, and a hose variable diameter switch 16 is arranged on the liquid outlet pipe 15; the separation pool 1 An infusion tube 12 is arranged between the funnel 10, a filter paper 11 is arranged on the funnel 10, and a magnetic stirring device 17 is arranged at the bottom of the separation tank 1. The separation pool 1 is a 1000ml suction filter bottle with an upper mouth, the height of the separation pool 1 is 22.5cm, the inner diameter of the mouth of th...

Embodiment 2

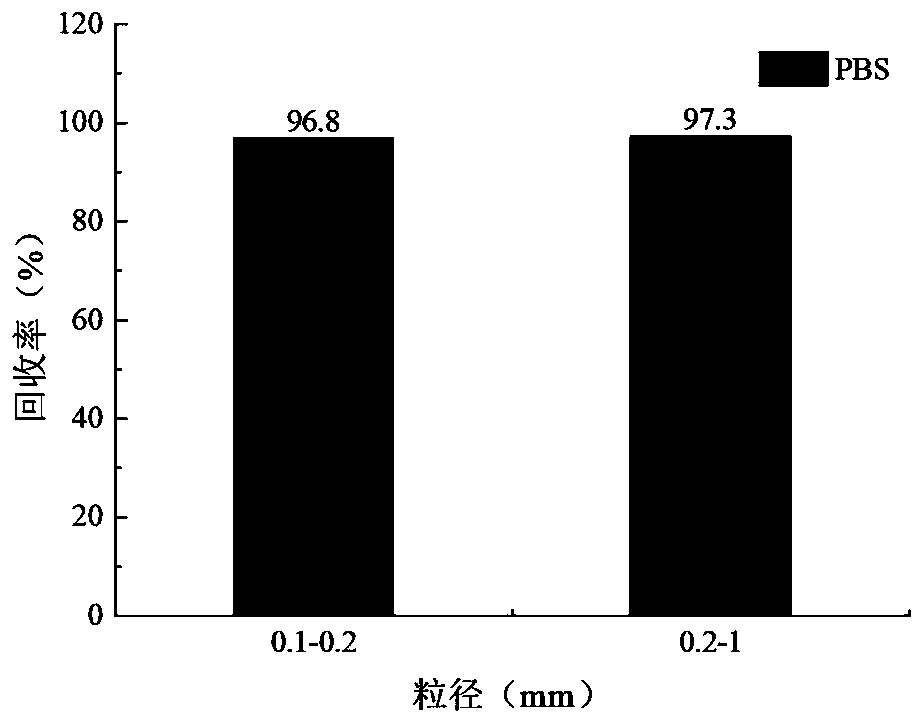

[0057] It is basically the same as Example 1, except that the simulated soil samples collected are polluted by biodegradable microplastics PBS of different particle sizes, and the recovery rate results of microplastics in the soil are as follows: image 3 shown.

Embodiment 3

[0059] It is basically the same as in Example 1, except that the simulated soil samples collected are polluted by non-degradable microplastics PVC of different particle sizes, and the recovery rate results of microplastics in the soil are as follows: Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com