Method for preparing curing agent by using gas-making slag and mineral waste residues as raw materials

A curing agent and gas-making technology, which is applied in cement production and other fields, can solve the problems of cracking of building materials and low material strength, and achieve the effects of low production cost, improved mechanical strength, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

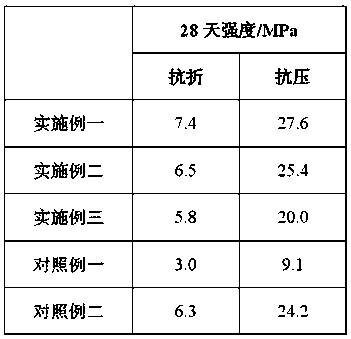

[0022] 1) Mix 20 parts of gas-forming slag, 2 parts of carbide slag, 0.03 part of borax and 5 parts of water evenly to make a mixture, and activate the mixture at 40°C for 3 hours;

[0023] 2) After the activated mixture is dried, it is mixed evenly with 55 parts of dry slag, 10 parts of modified gypsum, 3 parts of clinker and 1 part of polysilicon waste residue to obtain a curing agent with a specific surface area of 544 m 2 / kg.

[0024] The strength of the curing agent is tested according to GB / T17671-1999 "Cement Mortar Strength Test Method (ISO Method)".

Embodiment 2

[0026] 1) Mix 25 parts of gas-forming slag, 3.5 parts of carbide slag, 0.06 part of borax and 5 parts of water evenly to make a mixture, and activate the mixture at 50°C for 2 hours;

[0027] 2) After the activated mixture is dried, it is mixed evenly with 40 parts of dry slag, 7 parts of modified gypsum, 5 parts of clinker and 10 parts of polysilicon waste residue to obtain a curing agent with a specific surface area of 462 m 2 / kg.

[0028] The strength of the curing agent is tested according to GB / T17671-1999 "Cement Mortar Strength Test Method (ISO Method)".

Embodiment 3

[0030] 1) Mix 30 parts of gas-forming slag, 5 parts of carbide slag, 0.08 part of borax and 5 parts of water evenly to make a mixture, and activate the mixture at 60°C for 1 hour;

[0031] 2) After the activated mixture is dried, it is evenly mixed with 48 parts of dry slag, 5 parts of modified gypsum, 1 part of clinker and 6 parts of polysilicon waste residue to obtain a curing agent with a specific surface area of 416 m 2 / kg.

[0032] The strength of the curing agent is tested according to GB / T17671-1999 "Cement Mortar Strength Test Method (ISO Method)".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com