Single-component alkali-activated cement fireproof coating for tunnel and use method thereof

A technology for alkali-activated cement and fire-resistant coatings, applied in cement production, construction material processing, construction, etc., can solve the problems of high cost, inconvenient use of two-component formula, difficult construction, etc., to avoid injury and protect health. , The effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

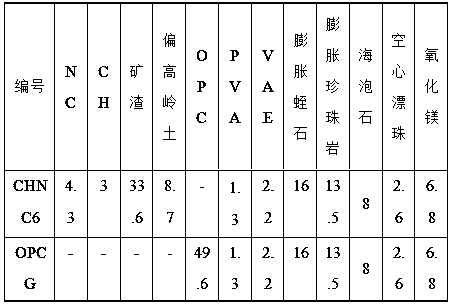

Embodiment 1

[0034]A single-component fireproof coating for tunnels, based on the sum of mass percentages of 100%: bonding materials: alkali-activated cement 49.6%, polyvinyl alcohol 1.3%, redispersible latex powder 2.2%; heat-insulating refractory material: expanded vermiculite 16% , expanded perlite 13.5%, sepiolite 8%, hollow floating beads 2.6%; flame retardant material: magnesium oxide 6.8%; the alkali-activated cement, according to the sum of mass percentages 100%: slag: 66.2%; metakaolin: 17.5%; Sodium Carbonate: 8.7%; Calcium Hydroxide: 7.6%.

[0035] The specific steps of the method of use are:

[0036] (1) Basic level cleaning: clean up the floating dust, residue and oil stains on the inner surface of the tunnel;

[0037] (2) Wetting with water: Use mechanical equipment to properly wet the concrete surface of the second lining of the tunnel, and then dry it until there is no clear water on the surface;

[0038] (3) Preparation of tunnel fireproof coating: first mix the one-comp...

Embodiment 2

[0043] A single-component fireproof coating for tunnels, based on the sum of mass percentages of 100%: bonding materials: alkali-activated cement 45%, polyvinyl alcohol 3%, redispersible latex powder 2.6%; heat-insulating refractory material: expanded vermiculite 20% , expanded perlite 10.9%, sepiolite 9%, hollow floating beads 1.5%; flame retardant material: magnesium oxide 8%; the alkali-activated cement, according to the sum of mass percentages 100%: slag: 65%; metakaolin: 20%; Sodium Carbonate: 7%; Calcium Hydroxide: 8%.

[0044] The specific steps of the method of use are:

[0045] (1) Basic level cleaning: clean up the floating dust, residue and oil stains on the inner surface of the tunnel;

[0046] (2) Wetting with water: Use mechanical equipment to properly wet the concrete surface of the second lining of the tunnel, and then dry it until there is no clear water on the surface;

[0047] (3) Preparation of fire-resistant coating for tunnels: First, mix the one-compon...

Embodiment 3

[0052] A single-component fireproof coating for tunnels, based on the sum of mass percentages of 100%: bonding materials: alkali-activated cement 55%, polyvinyl alcohol 1%, redispersible latex powder 1.2%; heat-insulating refractory material: expanded vermiculite 15.3% , expanded perlite 15%, sepiolite 5%, hollow floating beads 3.5%; flame retardant material: magnesium oxide 5%; the alkali-activated cement, according to the sum of mass percentages 100%: slag: 70%; metakaolin: 15%; Sodium Carbonate: 10%; Calcium Hydroxide: 5%.

[0053] The specific steps of the method of use are:

[0054] (1) Basic level cleaning: clean up the floating dust, residue and oil stains on the inner surface of the tunnel;

[0055] (2) Wetting with water: Use mechanical equipment to properly wet the concrete surface of the second lining of the tunnel, and then dry it until there is no clear water on the surface;

[0056] (3) Preparation of tunnel fire retardant coating: first mix the one-component a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Fire resistance time | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com