Method for determining content of tungsten element in nickel-based alloy

An element content, nickel-based alloy technology, applied in material excitation analysis, electrical excitation analysis, etc., can solve problems such as long detection period, detection range that cannot completely cover the range of tungsten element content, and cumbersome detection steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1: Determination of the content of tungsten in the nickel-based alloy sample 1 (nickel-chromium-molybdenum alloy) to be tested.

[0042] 1. Determination of analysis conditions

[0043] Module voltage: 8.0V; phase voltage: 3.5V; generator power: 60W; flushing time: 70s; integration time: 50s.

[0044] Due to the high content of molybdenum in the nickel-chromium-molybdenum alloy, when the wavelength of the tungsten element analysis spectrum is 220.45nm and 400.875nm, the molybdenum element interferes with the detection of tungsten element, so the selected wavelength is 400.988nm.

[0045] 2. Drawing and confirmation of calibration curve

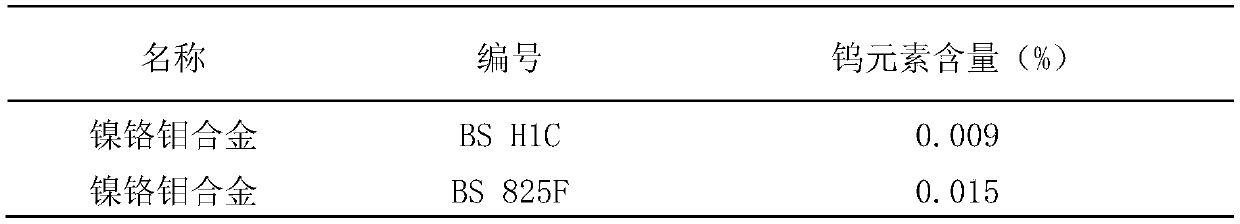

[0046] Table 1 standard sample

[0047]

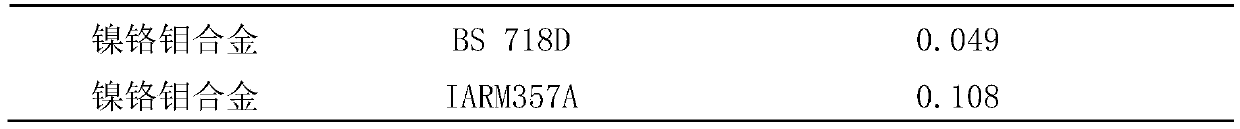

[0048]

[0049] Fix the above analysis conditions, and select 4 nickel-based alloy standard samples covering different gradient tungsten element contents as shown in Table 1 for the establishment of the calibration curve according to the needs. The average relative intensity, wi...

Embodiment 2

[0075] Example 2: Determination of the content of tungsten in the nickel-based alloy sample 2 (nickel-chromium-iron alloy).

[0076] 1. Determination of analysis conditions

[0077] Module voltage: 8.25V; phase voltage: 3.75V; generator power: 70W; flushing time: 80s; integration time: 55s.

[0078] Due to the high content of iron in nickel-chromium-iron alloy, when the wavelength of tungsten element analysis spectrum is 220.45nm and 400.988nm, the iron element interferes with the detection of tungsten element, so the selected wavelength is 400.875nm.

[0079] 1. Drawing and confirmation of calibration curve

[0080] Table 8 Standard Samples

[0081]

[0082] Fix the above analysis conditions, and select 4 nickel-based alloy standard samples covering different gradient tungsten element contents as shown in Table 1 for the establishment of the calibration curve according to the needs. The average relative intensity, with the tungsten element content as the abscissa, and t...

Embodiment 3

[0108] Embodiment 3: Determination of the content of tungsten in the nickel-based alloy sample 3 (nickel-chromium-cobalt alloy) to be tested.

[0109] 1. Determination of analysis conditions

[0110] Module voltage: 8.35V; phase voltage: 3.85V; generator power: 75W; flushing time: 85s; integration time: 60s.

[0111] Due to the high content of titanium in the nickel-chromium-cobalt alloy, when the wavelength of the tungsten element analysis spectrum is 400.875nm and 400.988nm, the titanium element interferes with the detection of the tungsten element, so the selected wavelength is 220.45nm.

[0112] 2. Drawing and confirmation of calibration curve

[0113] Table 15 Standard Samples

[0114]

[0115] Fix the above analysis conditions, and select 4 nickel-based alloy standard samples covering different gradient tungsten element contents as shown in Table 1 for the establishment of the calibration curve according to the needs. The average relative intensity, with the tungst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com