Positive electrode material of lithium-sulfur battery, preparation method of positive electrode material and lithium-sulfur battery

A positive electrode material, lithium-sulfur battery technology, applied in battery electrodes, lithium batteries, electrode manufacturing, etc., can solve the problems of active material loss, battery kinetic performance deterioration, internal resistance increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

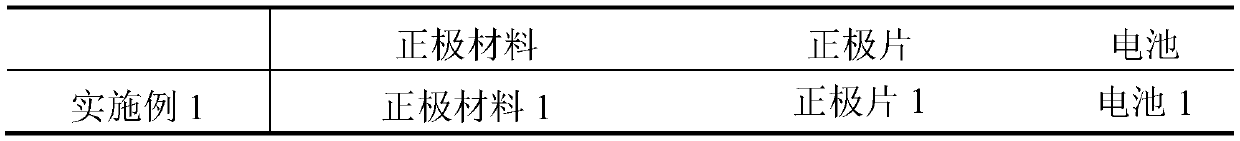

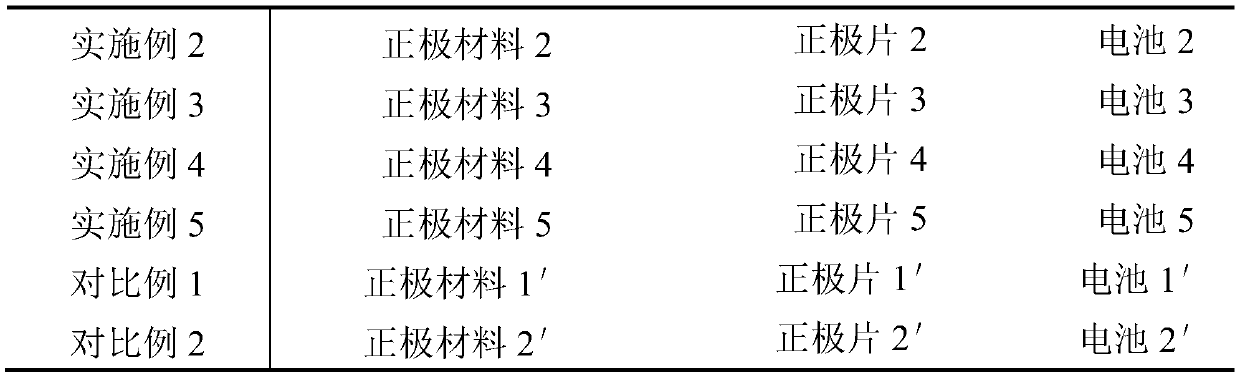

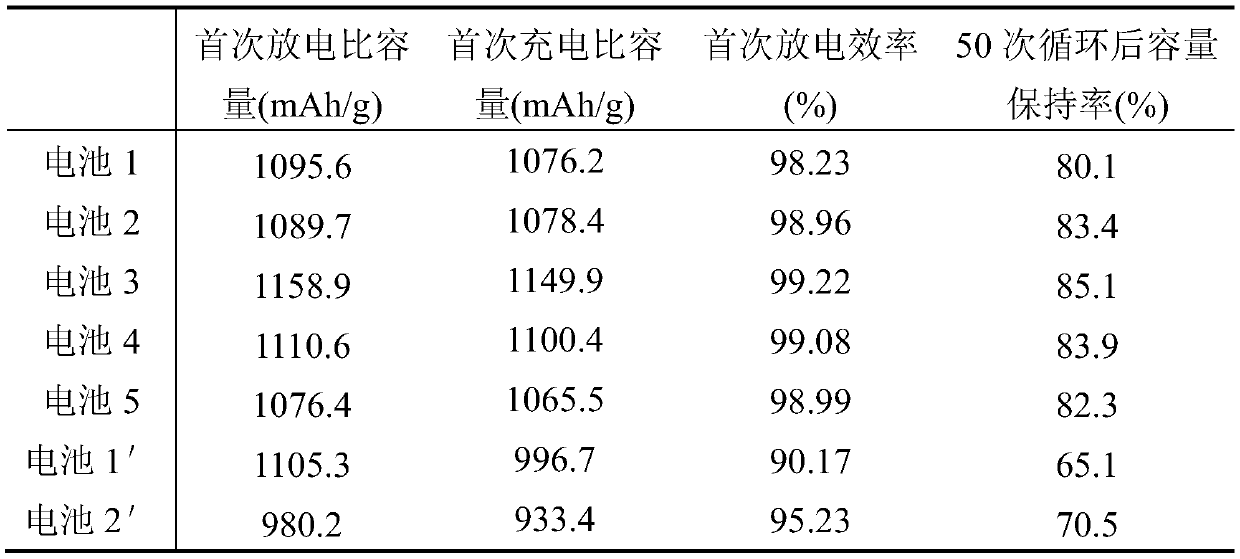

Examples

Embodiment 1

[0029] Take 10g of activated carbon-sulfur cathode material and disperse it in a cobalt nitrate hexahydrate solution with a concentration of 2g / L, disperse it by ultrasonic for 20min, impregnate with magnetic stirring for 10h, and then centrifuge to obtain a sulfur-carbon cathode with cobalt nitrate adsorbed, hereinafter referred to as cathode material 1 .

[0030] The activated carbon-sulfur cathode material is obtained by mixing commercial activated carbon and sublimed sulfur at a ratio of 30:70, and then treating it at 155°C for 12h in an argon atmosphere.

Embodiment 2

[0032]Take 15g of the S-C positive electrode with core-shell structure and disperse it in the nickel nitrate hexahydrate solution with a concentration of 3g / L, ultrasonically disperse for 40min, and centrifuge after immersing in magnetic stirring for 16h to obtain a sulfur-carbon positive electrode with nickel nitrate adsorbed on the carbon layer of the outer shell. Called positive electrode material 2.

[0033] The core-shell structured S-C positive electrode is prepared as follows: after mixing hollow carbon spheres and sublimed sulfur at a ratio of 30:70, it is obtained by treating at 155°C for 12h under an argon atmosphere.

[0034] The preparation method of hollow carbon spheres is as follows: SiO 2 The template spheres were uniformly dispersed in a Tris solution with a pH value of 8.5, and after adding dopamine hydrochloride, the magnetic stirring reaction was continued for 12 hours, and the SiO 2 The molar ratio of template to dopamine hydrochloride is 1:1, the mixed d...

Embodiment 3

[0036] Take 15g of S-C positive electrode with core-shell structure and disperse in Tris buffer solution with pH value of 8.5, ultrasonically disperse for 40min, add 1g of dopamine hydrochloride, and react for 22h under magnetic stirring. After centrifuging and washing the reaction solution, the polydopamine-coated core-shell structure S-C positive electrode was dispersed in a copper sulfate solution with a concentration of 3g / L and magnetically stirred for 10h, centrifuged, washed, and dried to obtain polydopamine-Cu 2+ The coated S-C positive electrode with a core-shell structure is referred to as the positive electrode material 3 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com