Hydrophilic self-cleaning oil-water separation membrane and preparation method thereof

An oil-water separation membrane and self-cleaning technology, applied in the field of membrane separation, can solve problems such as separation flux and oil-water separation efficiency decline, membrane surface pollution, and restrictions on the development and application of membrane separation technology, and achieve good anti-pollution performance and repeatability The effect of good, good cycle stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

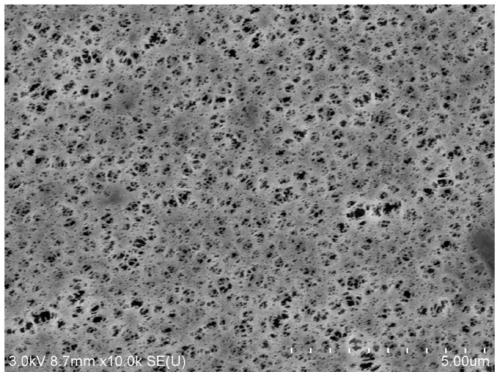

Image

Examples

Embodiment 1

[0023] (1) Dopamine modification: soak the polyvinylidene fluoride ultrafiltration membrane in a dopamine solution of 1 g / L and pH value of 8.5 for 15 minutes, self-assemble to form a polydopamine modification layer, take it out and wash it, and obtain a dopamine-modified polyvinylidene fluoride Ultrafiltration membrane;

[0024] (2) Quantum dot deposition: the dopamine-modified ultrafiltration membrane prepared in step (1) is immersed in a 0.01% graphene oxide quantum dot aqueous suspension for 10 min, and the graphene oxide quantum dot layer is deposited on the membrane surface by means of dopamine , to prepare quantum dot deposition film;

[0025] (3) In-situ cross-linking: the quantum dot deposition film prepared in step (2) is immersed in the MES buffer solution containing EDC and NHS, the pH value is 4, the total concentration of EDC and NHS is 0.01mol / L, EDC and NHS The molar ratio of NHS is 1:1, and the hydrophilic self-cleaning oil-water separation membrane is prepar...

Embodiment 2

[0027] (1) Dopamine modification: Soak the polyvinylidene fluoride ultrafiltration membrane in a 3g / L dopamine solution with a pH value of 8.5 for 25 minutes, self-assemble to form a polydopamine modification layer, take it out and wash it, and obtain a dopamine-modified polyvinylidene fluoride Ultrafiltration membrane;

[0028] (2) Quantum dot deposition: immerse the dopamine-modified ultrafiltration membrane prepared in step (1) into a 1.0% graphene oxide quantum dot aqueous suspension for 10 min, and deposit a graphene oxide quantum dot layer on the membrane surface by means of dopamine , to prepare quantum dot deposition film;

[0029] (3) In-situ cross-linking: the quantum dot deposition film prepared in step (2) is immersed in the MES buffer solution containing EDC and NHS, the pH value is 6.5, the total concentration of EDC and NHS is 0.1mol / L, EDC and NHS The molar ratio of NHS was 3:1, and the hydrophilic self-cleaning oil-water separation membrane was prepared after...

Embodiment 3

[0031] (1) Dopamine modification: Soak the polyvinylidene fluoride ultrafiltration membrane in a 3g / L dopamine solution with a pH value of 8.5 for 20 minutes, self-assemble to form a polydopamine modification layer, take it out and wash it, and obtain a dopamine-modified polyvinylidene fluoride Ultrafiltration membrane;

[0032] (2) Quantum dot deposition: the dopamine-modified ultrafiltration membrane prepared in step (1) is immersed in a 2% graphene oxide quantum dot aqueous suspension for 30 min, and the graphene oxide quantum dot layer is deposited on the membrane surface by means of dopamine , to prepare quantum dot deposition film;

[0033] (3) In-situ cross-linking: the quantum dot deposition film prepared in step (2) is immersed in the MES buffer solution containing EDC and NHS, the pH value is 5.5, the total concentration of EDC and NHS is 0.05mol / L, EDC and NHS The molar ratio of NHS is 1:1, and after an activation reaction at room temperature for 1 h, a hydrophilic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com