Ceramic powder reinforced multilayer metal and intermetallic compound composite structure and preparation method thereof

A technology of intermetallic compounds and ceramic powders, applied in chemical instruments and methods, armor plate structures, metal layered products, etc., can solve problems such as low protection coefficient, structural design defects, and poor ability to resist multiple bullets, and achieve Avoid protection failure, good compactness, and delay premature failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

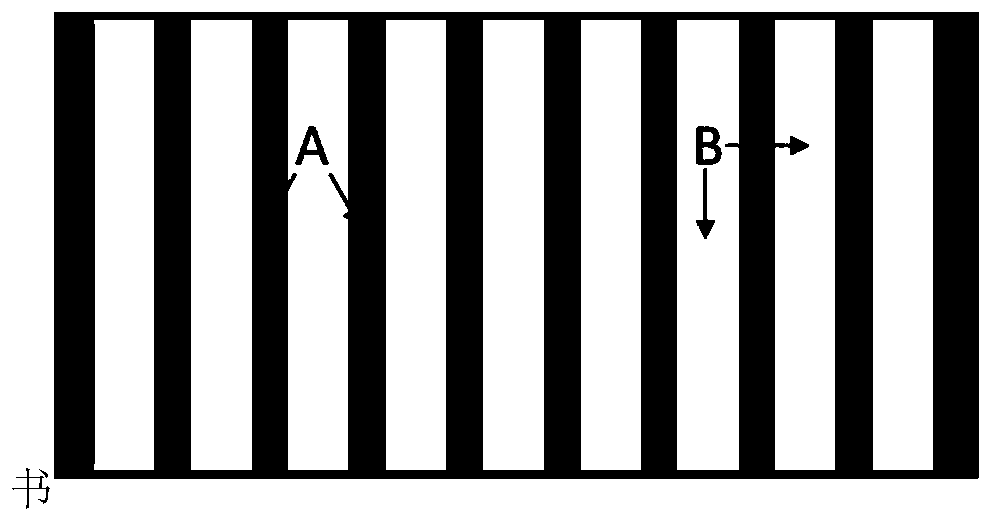

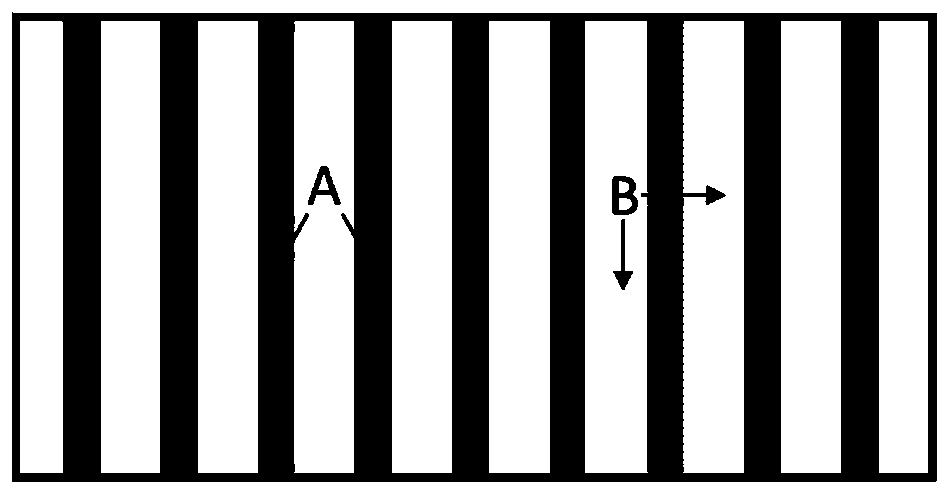

[0032] Example 1: A ceramic powder reinforced multilayer metal and intermetallic compound composite structure and its preparation method:

[0033]The ceramic powder reinforced multilayer metal and intermetallic compound composite structure is a multilayer structure, which is composed of metal plates and ceramic metal plates alternately stacked, and the interface is compounded by hot pressing and diffusion, and the relative melting point of the metal in the ceramic metal plates is higher than Metal in sheet metal. The ceramic metal plate is spray-coated by tungsten carbide ceramic powder on a 1mm thick TC4 titanium alloy metal plate at strip-like intervals, wherein the thickness of the strip-shaped ceramic layer is 0.5mm, and the spacing distance is greater than the width of the ceramic powder layer by 3mm. The density of the ceramic layer is 95%.

[0034] The multilayer structure includes 6 composite units. A layer of 0.3mm aluminum plate is placed between two composite unit...

Embodiment 2

[0042] Example 2: A ceramic powder reinforced multilayer metal and intermetallic compound composite structure and its preparation method:

[0043] The ceramic powder reinforced multilayer metal and intermetallic compound composite structure is a multilayer structure, which is composed of metal plates and ceramic metal plates alternately stacked, and the interface is compounded by hot pressing and diffusion, and the relative melting point of the metal in the ceramic metal plates is higher than Metal in sheet metal. The ceramic metal plate is spray-coated on a 10mm thick AZ31 magnesium alloy metal plate by tungsten carbide ceramic powder at strip-like intervals, wherein the thickness of the strip-shaped ceramic layer is 3mm, and the spacing distance is greater than the width of the ceramic powder layer by 8mm. The density of the ceramic layer is 90%.

[0044] The multilayer structure includes 8 composite units. A layer of 5mm magnesium metal plate is placed between the two com...

Embodiment 3

[0052] Example 3: A ceramic powder reinforced multilayer metal and intermetallic compound composite structure and its preparation method:

[0053] The ceramic powder reinforced multilayer metal and intermetallic compound composite structure is a multilayer structure, which is composed of metal plates and ceramic metal plates alternately stacked, and the interface is compounded by hot pressing and diffusion, and the relative melting point of the metal in the ceramic metal plates is higher than Metal in sheet metal. The ceramic metal plate is spray-coated on a 0.2 mm thick pure titanium metal plate by tungsten carbide ceramic powder at strip intervals, wherein the thickness of the strip ceramic layer is 0.1 mm, and the interval distance is greater than the width of the ceramic powder layer by 1 mm. The density of the strip ceramic layer is 99.9%.

[0054] The multilayer structure includes 4 composite units. A layer of 0.1mm TC is placed between the two composite units 4 Titan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com