Method for preparing phosphate fertilizer from municipal sludge

A municipal sludge and phosphate fertilizer technology, applied in the field of solid waste recycling, can solve the problems of low phosphorus extraction efficiency and high risk of heavy metal environmental pollution, etc., and achieve good practical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

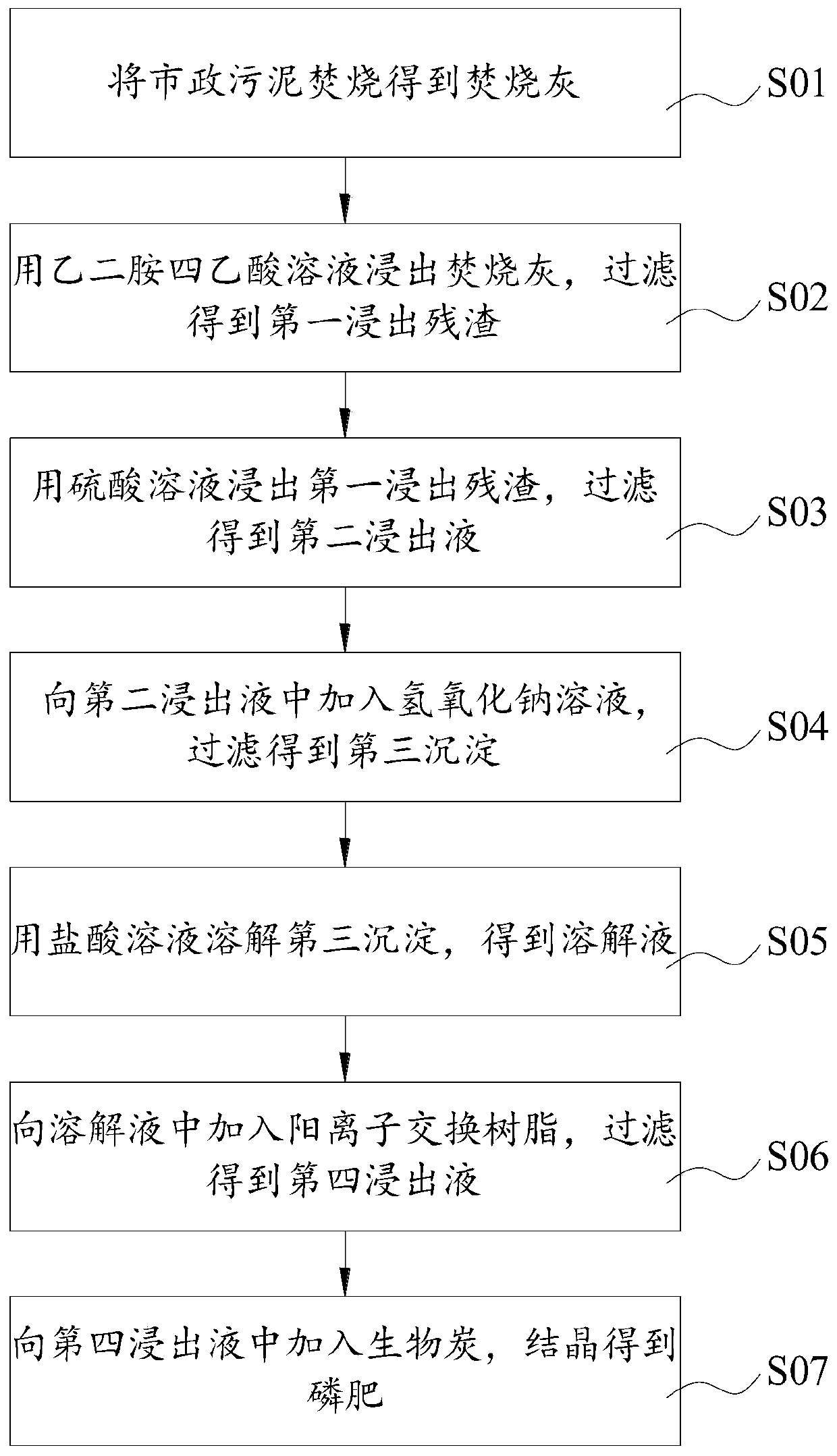

[0033] figure 1 It is the method flowchart of the method for preparing phosphate fertilizer with municipal sludge of the present invention, as figure 1 As shown, the present embodiment provides a method for preparing phosphate fertilizer from municipal sludge, comprising the following steps:

[0034] S01. Incinerate municipal sludge to obtain incineration ash.

[0035] In step S01 of this embodiment, since the municipal sludge contains abundant organic residues, and phosphorus element is also in these organic substances, the first thing to be removed is the organic substances in the municipal sludge, and most of the organic substances are combustible substances. Therefore, toxic and harmful organic residues in municipal sludge can be removed by incineration. These organic residues are thermally oxidized and decomposed during the combustion process, and finally the remaining incineration ash is inorganic residues, and the form of phosphorus is also From organic phosphorus to ...

Embodiment 2

[0068] As yet another embodiment of the present invention, different from the previous embodiment:

[0069] In step S01 of this embodiment, specifically take 1 ton of municipal sludge, and use a plate and frame filter press to first filter the municipal sludge to dehydrate the municipal sludge, and obtain 10 kg of dewatered sludge with a moisture content of 50%. , Put the dewatered sludge into the chain furnace and incinerate completely at an ambient temperature of 850°C. After the incineration is completed, 1kg of incineration ash will be obtained.

[0070] In step S02 of this embodiment, the concentration of the EDTA solution is 0.02 mol / L, and the addition amount of the EDTA solution is 20 kg. During the leaching process, after stirring for 90 minutes, let it stand for 90 minutes, and filter to obtain 0.95 kg of the first leaching residue.

[0071] In step S03 of this embodiment, the concentration of the sulfuric acid solution is 0.5 mol / L, and the addition amount of the s...

Embodiment 3

[0079] As yet another embodiment of the present invention, different from Embodiment 1,

[0080] In step S01 of this embodiment, specifically take 2 tons of municipal sludge, and use a plate and frame filter press to first filter the municipal sludge to dehydrate the municipal sludge, and obtain 10 kg of dewatered sludge with a moisture content of 50%. , Put the dewatered sludge into the chain furnace and incinerate completely at an ambient temperature of 900°C. After the incineration is completed, 2kg of incineration ash will be obtained.

[0081] In step S02 of this embodiment, the concentration of the EDTA solution is 0.02 mol / L, and the addition amount of the EDTA solution is 40 kg. During the leaching process, after stirring for 90 minutes, let it stand for 90 minutes, and filter to obtain 1.9 kg of first leaching residue.

[0082] In step S03 of this embodiment, the concentration of the sulfuric acid solution was 0.3 mol / L, and the addition amount of the sulfuric acid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com