ODB-2 dye impurity and preparation method thereof

A technology of ODB-2 and dyes, which is applied in the field of preparation of ODB-2 impurities of fluoran-based thermal pressure-sensitive dyes, can solve the problems of undisclosed and other issues, and achieve the effects of easy-to-obtain raw materials, high yield, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The specific examples of the preparation method provided by the present invention are as follows to further describe the technical solution of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included within the protection scope of the present invention.

[0023] The structural formula of the new ODB-2 dye impurity of the present invention is following formula I:

[0024]

[0025] The synthetic method of new ODB-2 dye impurity in the present embodiment is as follows:

Embodiment 1

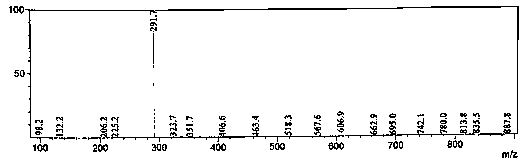

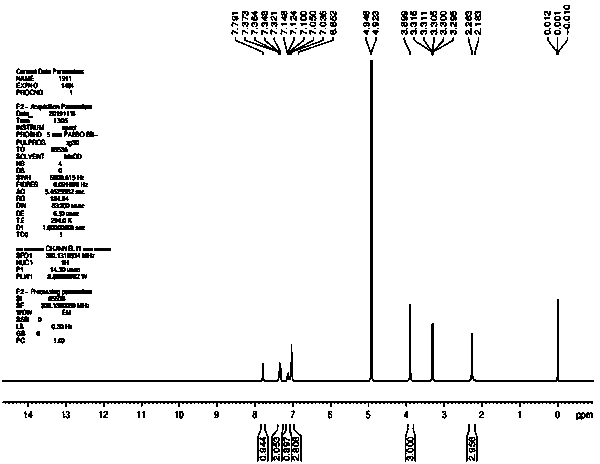

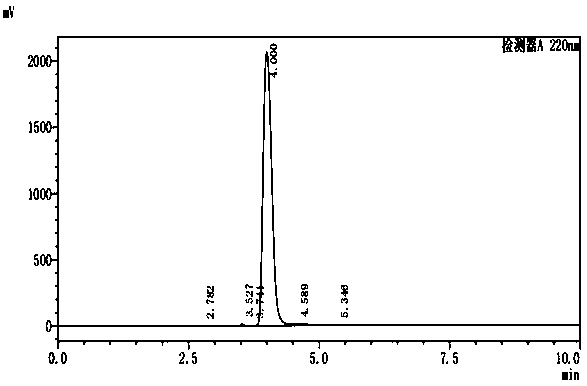

[0027] Put 50 g of 100% concentrated sulfuric acid into a 100 ml three-necked flask at room temperature, start stirring, add 10 g of 2-methyl-4-methoxydiphenylamine solid to it in small amounts, slowly raise the temperature to 50 ° C, and all the solids are dissolved. The process of the reaction was controlled in the middle. After 0.5 h of reaction, the raw material point disappeared, and the reaction solution was slowly dropped into 500 ml of distilled water, all dissolved, and 13.5 g of solid precipitated after cooling, which was the target product ODB-2 dye impurity, with a yield of 98.47% and a purity of 99.41%. Perform mass spectrometry analysis on the generated impurities, as shown in the attached figure 2 ; HPLC analysis of purity, as attached image 3 .

Embodiment 2

[0029] Under the same environment as in Example 1, take a 100 ml three-necked bottle, add 30 g of 100% concentrated sulfuric acid thereinto, start stirring, and add 10 g of 2-methyl-4-methoxydiphenylamine solid to it in small amounts for several times, slowly Raise the temperature to 50°C, all the solids are dissolved, and the reaction process is controlled centrally. After 0.5 h of reaction, most of the raw materials remain, continue to heat up to 80°C, and react again for 0.5 h, and about 20% of the raw materials remain. Drop it into 500 ml of distilled water to form White flocculent insoluble matter, the reaction solution was taken for high-performance liquid chromatography analysis, the purity was 79.37%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com