Phosphorus-free, nitrogen-free and chromium-free stainless steel passivation solution

A technology of stainless steel and passivation solution, which is applied in the coating process of metal materials, etc., can solve the problems of endangering the physical safety of workers in the environment, and cannot meet the requirements of non-toxic and harmless, and achieves strong compactness, good film-forming effect, and stable system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

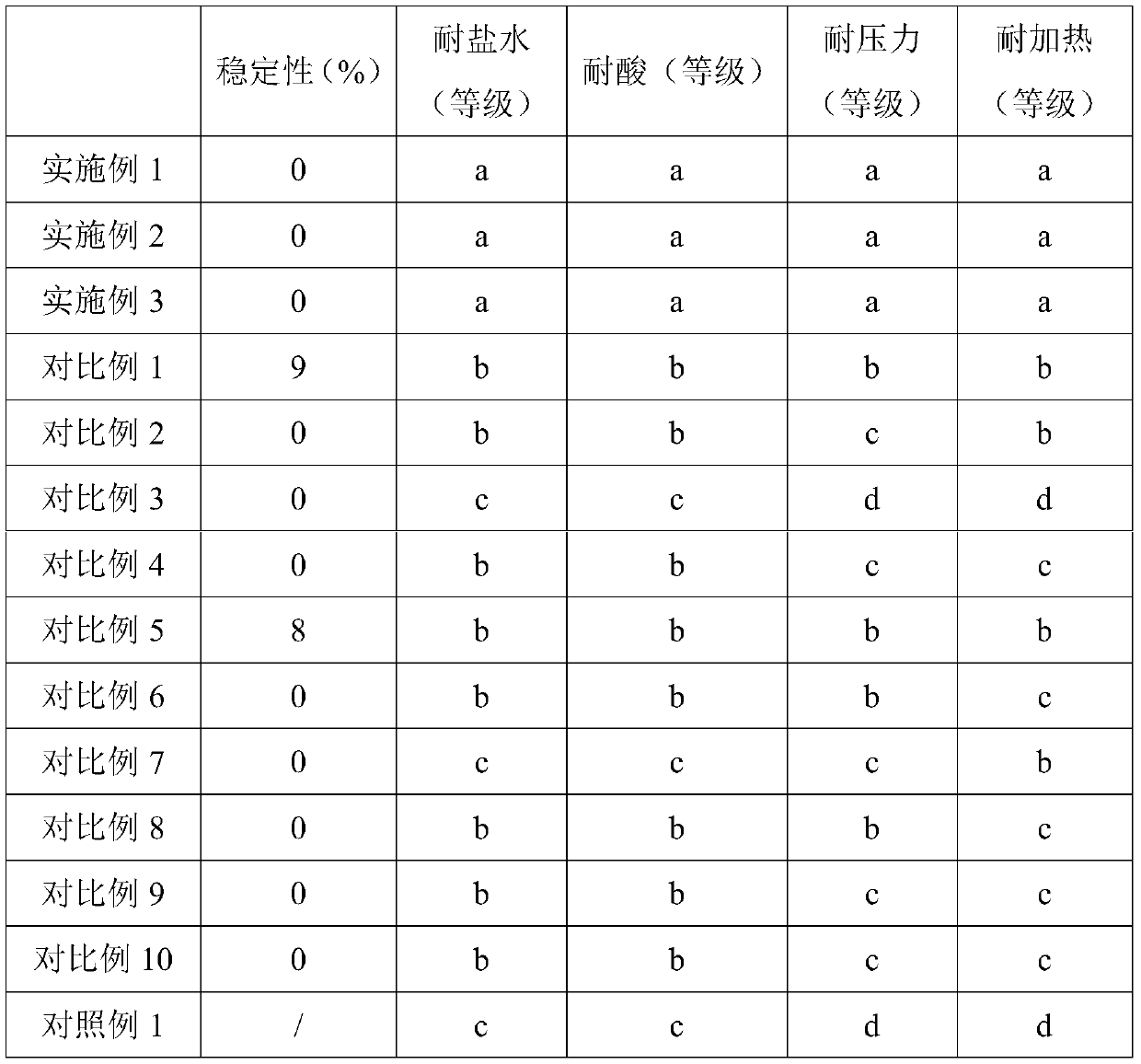

Examples

preparation example Construction

[0056] The second aspect of the present invention provides a preparation method according to the phosphorus- and nitrogen-free chromium-free stainless steel passivation solution, which at least includes the following steps: adding each component to the reactor, mixing and stirring uniformly, and adding a pH regulator It is obtained after adjusting the pH.

[0057] In a preferred embodiment, the preparation method of the phosphorus- and nitrogen-free chromium-free stainless steel passivation solution includes at least the following steps: adding each component to the reactor, mixing and stirring uniformly, adding a pH regulator to adjust It is obtained after pH is 2~3.5.

[0058]

[0059] The pH adjusting agent of the present invention includes an acidic pH adjusting agent and an alkaline pH adjusting agent.

[0060] In a preferred embodiment, the acidic pH adjuster is selected from one or more combinations of hydrofluoric acid, dilute sulfuric acid, hydrochloric acid, and citric aci...

Embodiment 1

[0067] Embodiment 1 of the present invention provides a phosphorus-free, nitrogen-free, chromium-free stainless steel passivation solution. In terms of mass percentage, the preparation raw materials include at least 2% oxidant, 2% film-forming agent, 3% complexing agent, 0.05% penetrant, and 0.6% The film fixing agent and the balance is deionized water; the film fixing agent is a dicarboxylic acid salt with 8 to 13 carbon atoms.

[0068] The oxidant is hydrogen peroxide; the film-forming agent is sodium molybdate; and the complexing agent is tannic acid.

[0069] The penetrant is an organosiloxane; the organosiloxane includes 1,8-bis(trimethoxysilyl)octane and methyltrimethoxysilane; the 1,8-bis(trimethoxysilane) The weight ratio of silyl)octane and methyltrimethoxysilane is 0.6:1.

[0070] The dicarboxylic acid salt is sodium phthalate.

[0071] In terms of mass percentage, the preparation raw material also includes 0.3% polyvinyl alcohol.

[0072] The polyvinyl alcohol includes a hi...

Embodiment 2

[0079] Example 2 of the present invention provides a phosphorus- and nitrogen-free chromium-free stainless steel passivation solution. In terms of mass percentage, the preparation raw materials include at least 5% oxidant, 5% film-forming agent, 10% complexing agent, 0.2% penetrant, and 2% The film fixing agent and the balance is deionized water; the film fixing agent is a dicarboxylic acid salt with 8 to 13 carbon atoms.

[0080] The oxidant is hydrogen peroxide; the film-forming agent is sodium molybdate; and the complexing agent is tannic acid.

[0081] The penetrant is an organosiloxane; the organosiloxane includes 1,8-bis(trimethoxysilyl)octane and methyltrimethoxysilane; the 1,8-bis(trimethoxysilane) The weight ratio of silyl)octane and methyltrimethoxysilane is 1:1.

[0082] The dicarboxylic acid salt is sodium phthalate.

[0083] In terms of mass percentage, the preparation raw material also includes 2% polyvinyl alcohol.

[0084] The polyvinyl alcohol includes a high degree o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com