Preparation method of liquid crystal polymer thin film

A technology of liquid crystal polymer and polyimide film, which is applied in the direction of melt spinning, fabric surface trimming, heating/cooling fabric, etc., can solve the problems of uncontinuous transverse strength and high equipment requirements, and is conducive to large-scale industrialization The production and preparation process is simple and the operability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

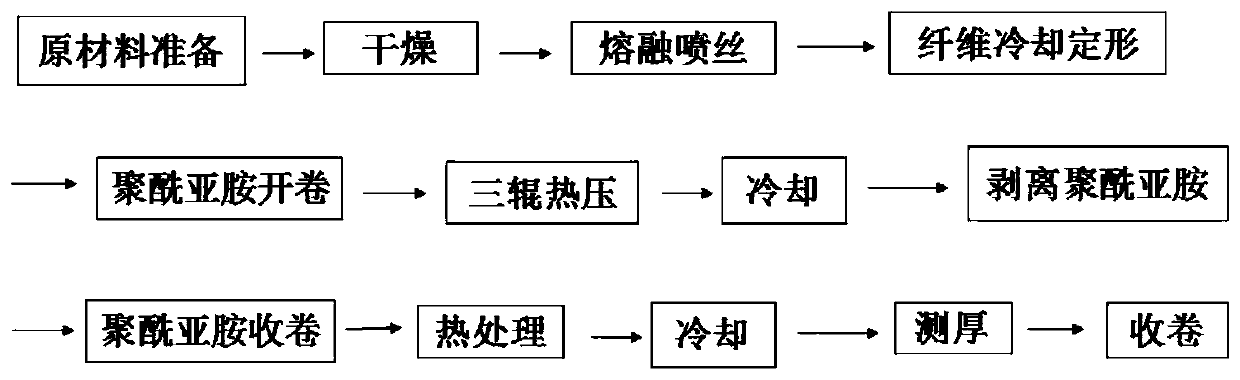

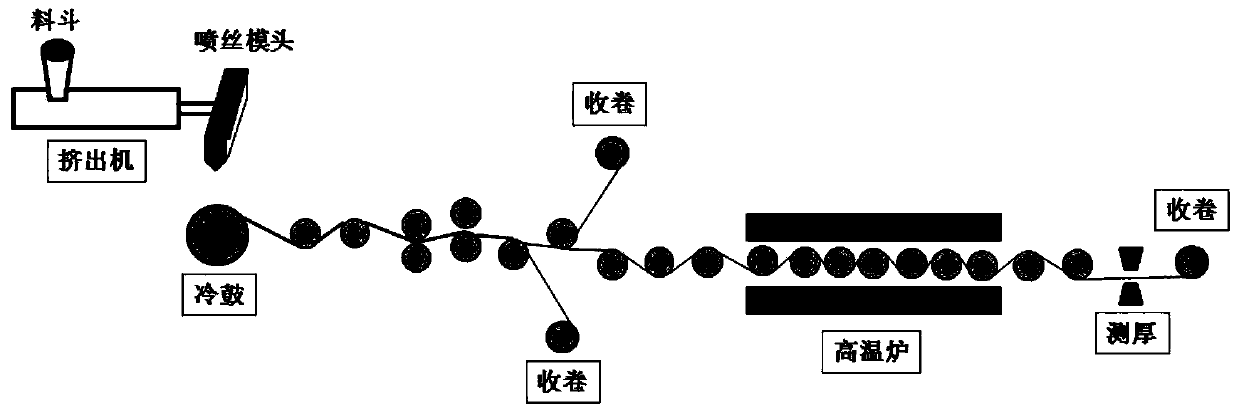

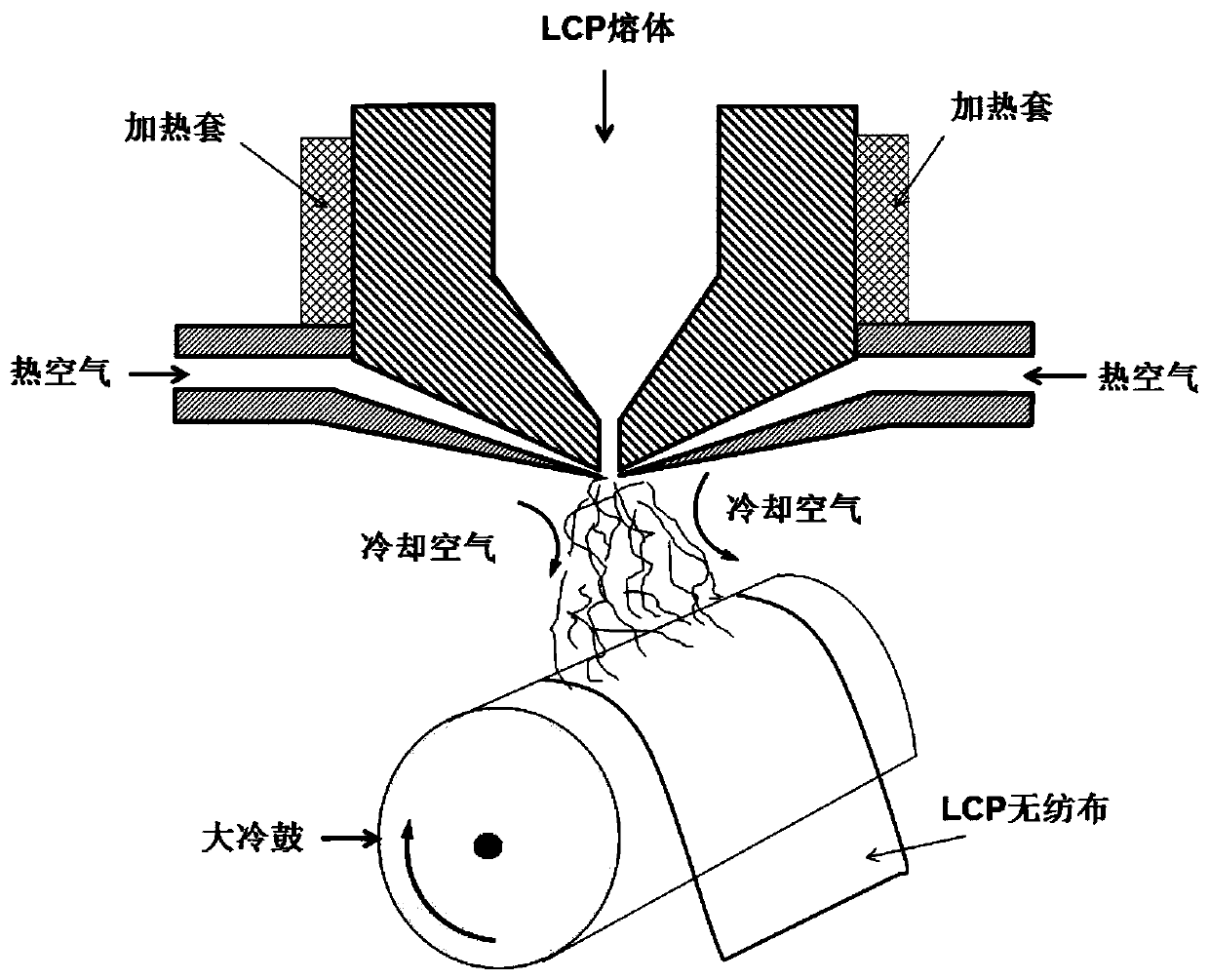

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing a liquid crystal polymer film, the steps are: adding a mixture of LCP resins C950 and E950i (mass ratio: 1:1) into a drying tank, and drying at 150° C. for 4 hours. Then put the dried resin into the melt spinning equipment, the extrusion temperature is 350°C, the hot air pressure is 0.2MPa, the cold drum temperature is 15°C, and then the film is formed by hot pressing with two rollers. The temperature is 280°C, the temperature of the hot pressing roll is 350°C, both sides are protected by polyimide film (thickness 0.188mm), the line pressure of the roll is 120daN / cm, and the temperature of the cooling roll is 170°C. After the polyimide film was peeled off manually, the LCP film was subjected to high-temperature heat treatment at a temperature of 240°C and a vehicle speed of 3.5m / min. After cooling, the LCP film is wound up.

Embodiment 2

[0033] A method for preparing a liquid crystal polymer film, the steps are: adding LCP resin A950 into a drying jar, and drying at 150° C. for 4 hours. Then put the dried resin into the melt spinning equipment, the extrusion temperature is 300°C, the hot air pressure is 0.1MPa, the cold drum temperature is 35°C, and then the film is formed by hot pressing with two rollers, and the temperature of the preheating roller is The temperature is 250°C, the temperature of the hot pressing roll is 300°C, both sides are protected by polyimide film (thickness 0.15mm), the line pressure of the roll is 90daN / cm, and the temperature of the cooling roll is 160°C. After the polyimide film was peeled off manually, the LCP film was subjected to high-temperature heat treatment at a temperature of 220°C and a vehicle speed of 1.5m / min. After cooling, the LCP film is wound up.

Embodiment 3

[0035]A method for preparing a liquid crystal polymer film, the steps are: adding LCP resin KD100 into a drying tank, and drying at 150° C. for 4 hours. Then put the dried resin into the melt spinning equipment, the extrusion temperature is 300°C, the hot air pressure is 0.5MPa, the cold drum temperature is 20°C, and then the film is formed by hot pressing with two rollers, and the temperature of the preheating roller is The temperature is 245°C, the temperature of the hot pressing roll is 295°C, both sides are protected by polyimide film (thickness 0.188mm), the line pressure of the roll is 60daN / cm, and the temperature of the cooling roll is 200°C. After the polyimide film was peeled off manually, the LCP film was subjected to high-temperature heat treatment at a temperature of 230° C. and a vehicle speed of 5 m / min. After cooling, the LCP film is wound up.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com