Low-reflectivity black film, and method for manufacturing laminate

A technology of a low-reflection film and a manufacturing method, which can be applied to devices, coatings, instruments and other directions for coating liquid on the surface, can solve the problems of strong scattering and increased scattering reflectivity, and achieve the effect of excellent reflectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

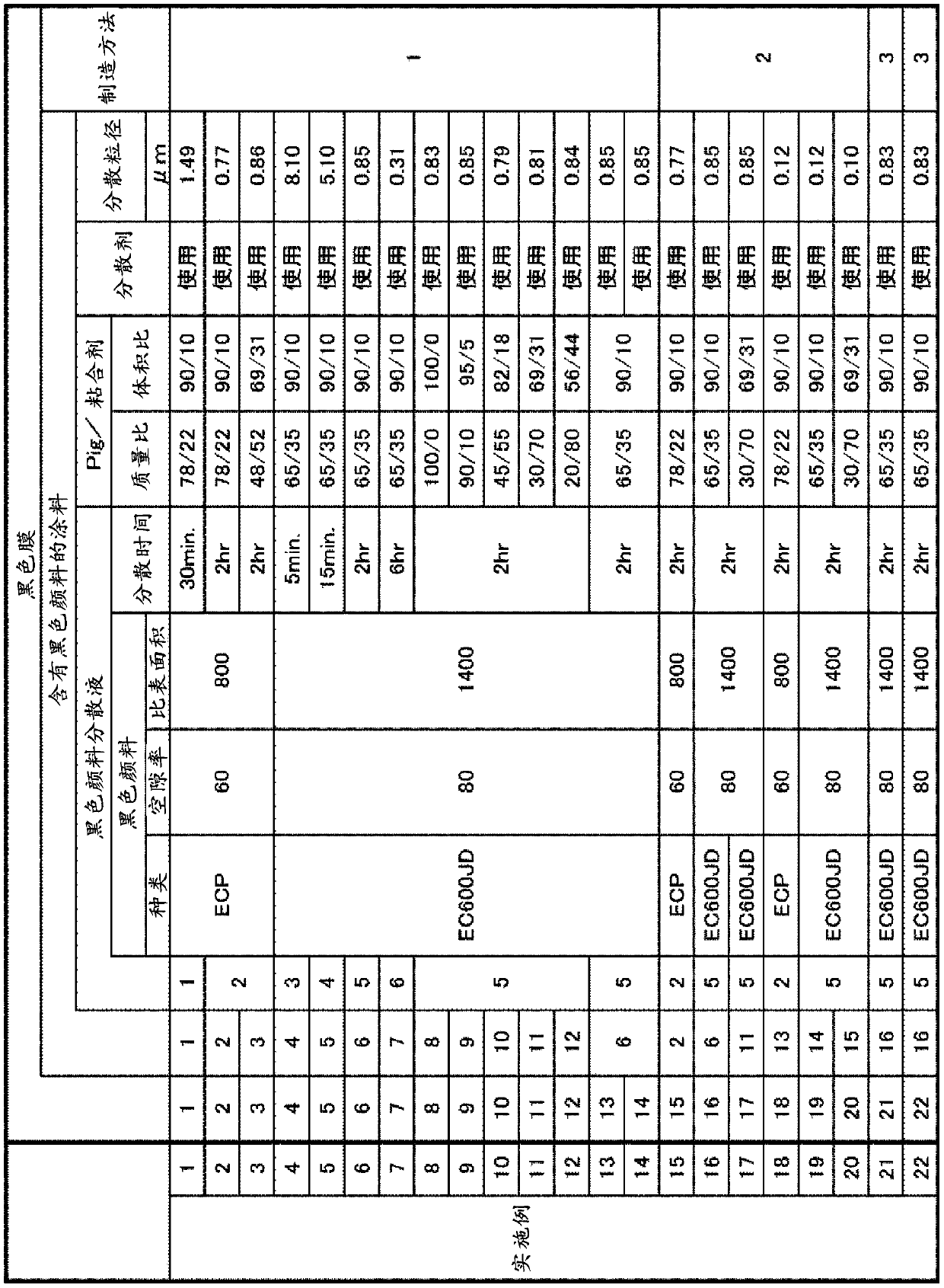

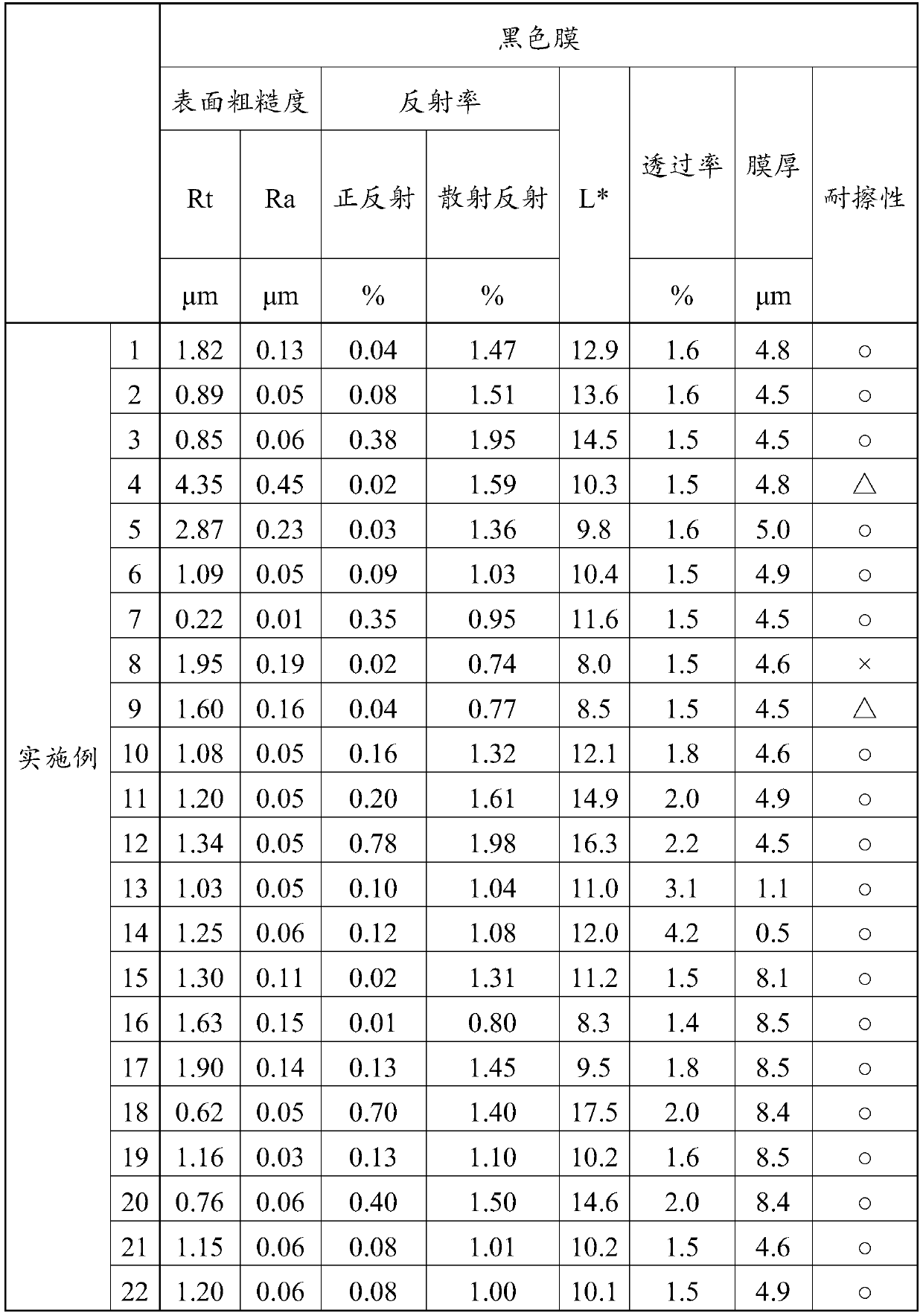

[0126] Hereinafter, although an Example is given and the present invention is demonstrated in detail, this invention is not limited to these Examples. In addition, "part" means a mass part unless otherwise noted.

[0127]

[0128] The hydroxyl value (OHV) and acid value (AV) were calculated|required based on JISK0070.

[0129]

[0130] The molecular weight distribution was measured using a gel permeation chromatography (Gel Permeation Chromatography, GPC) apparatus (HLC-8220 manufactured by Tosoh Corporation), and the mass average molecular weight (Mw) was calculated|required. Mw is the converted molecular weight using polystyrene as a standard substance. The measurement conditions are shown below.

[0131] Column: The following columns were connected in series and used.

[0132] Guard column H manufactured by Tosoh Corporation XL -H,

[0133] TSKgelG5000H manufactured by Tosoh Corporation XL ,

[0134] TSKgelG4000H manufactured by Tosoh Corporation XL ,

[0135] ...

Synthetic example 1

[0141] [Synthesis Example 1] (Binder Component: Synthesis of Solution of Acrylic Resin)

[0142] In a reaction vessel with a stirrer, a thermometer, a reflux cooler, a dropping device, and a nitrogen gas introduction pipe, add 20.0 parts of methyl methacrylate, 0.6 parts of methacrylic acid, 3.0 parts of 2-hydroxyethyl methacrylate, and 76.4 parts of n-butyl acrylate, and 100 parts of propylene glycol 1-monomethyl ether 2-acetate. These raw materials were heated up to 100 degreeC, stirring and mixing under nitrogen atmosphere. Thereafter, 0.5 part of azobisisobutyronitrile (azobisisobutyronitrile) was added, and a polymerization reaction was performed for 2 hours. Then, 0.5 parts of azobisisobutyronitrile was added every hour to perform a polymerization reaction until the conversion rate reached 98% or more. After confirming that the conversion rate was 98% or more, 50 parts of propylene glycol 1-monomethyl ether 2-acetate was added to the reaction solution for dilution. Th...

Synthetic example 2

[0143] [Synthesis Example 2] (Adhesive Component 1: Synthesis of Acrylic Resin Solution)

[0144] In a reaction vessel with a stirrer, a thermometer, a reflux cooler, a dropping device and a nitrogen inlet pipe, add 60 parts of n-butyl acrylate, 30 parts of methacrylate, 2-ethylhexyl acrylate (2-ethylhexyl acrylate) 5 parts, 5 parts of acrylic acid, 70 parts of ethyl acetate, and 0.10 parts of 2,2'-azobis(2-methylbutyronitrile). These raw materials were reacted at reflux temperature for 7 hours while stirring and mixing them under a nitrogen atmosphere. After completion of the reaction, ethyl acetate was added to the reaction solution for dilution to obtain a solution of an acrylic resin having a solid content of 30% and a weight average molecular weight Mw of 980,000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com