Electroconductive tape and method for manufacturing same

A conductive tape, conductive technology, applied in chemical instruments and methods, electrical components, magnetic field/electric field shielding, etc. Excellent strength and handleability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] (Making conductive mesh fabric)

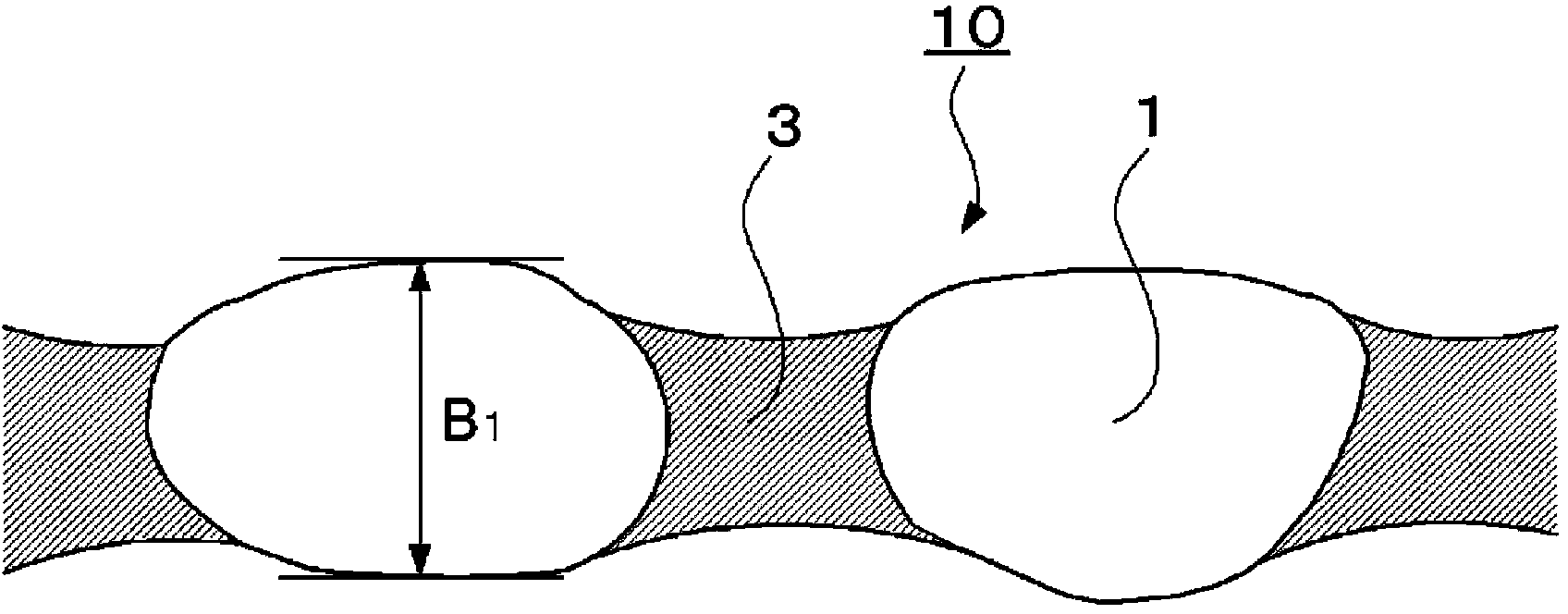

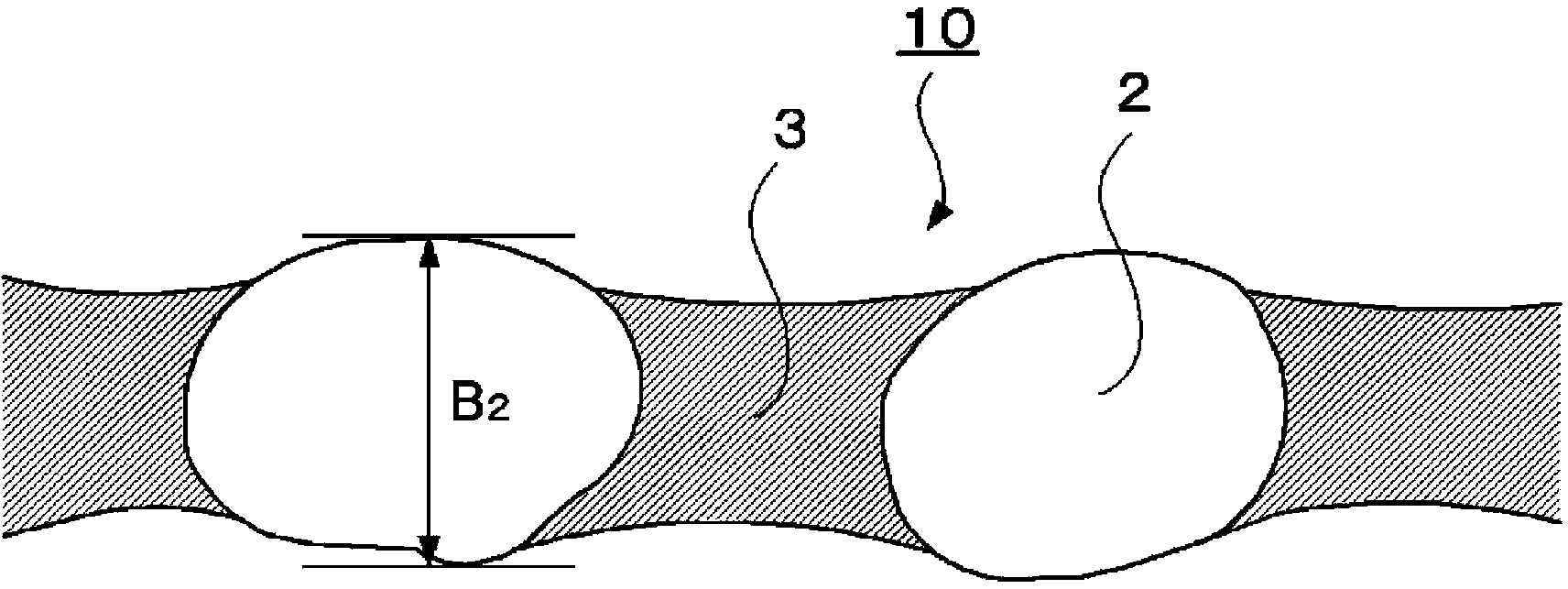

[0087] Pretreated at 190°C, the warp and weft are made of monofilaments made of polyethylene terephthalate with a diameter of 27 μm (denier 8 dtex), and the density of warp and weft is 132 per inch. Flat fabric. Thereafter, calendering was performed at a temperature of 150° C. and a linear pressure of 30 kg / cm. This mesh flat fabric was immersed in a 40° C. aqueous solution containing 0.3 g / L of palladium chloride, 30 g / L of stannous chloride, and 300 ml / L of 36% hydrochloric acid for 2 minutes, and then washed with water. Next, it was immersed in fluoboric acid at an acid concentration of 0.1N at 30° C. for 5 minutes, and then washed with water. Next, it was immersed in a 30° C. electroless copper plating solution containing 7.5 g / L of copper sulfate, 30 ml / L of 37% formaldehyde, and 85 g / L of potassium sodium tartrate for 5 minutes, and then washed with water. Next, in a nickel electroplating solution containing 300g / L of nickel su...

Embodiment 2

[0099] (Making conductive mesh fabric)

[0100] Pretreated at 190°C, the warp and weft are made of monofilaments made of polyethylene terephthalate with a diameter of 27 μm (denier 8 dtex), and the density of warp and weft is 132 per inch. Flat fabric. Then, plating was performed in the same manner as in Example 1. The maximum thickness of the obtained conductive mesh fabric was 47 μm, and its opening ratio was 72%.

[0101] (adhesive coating treatment)

[0102] Using a comma direct coater, the gap between the release sheet (SLK-80KCT: manufactured by Sumika Paper Co., Ltd.) and the comma head was adjusted to 110 μm, and the same adhesive coating liquid as in Example 1 was evenly applied. Then, it was made to pass through the inside of the dryer of 120 degreeC, and the adhesive layer of thickness 40 micrometers was obtained. The prepared conductive mesh fabric and other release sheets (EKR90R: manufactured by Lintec Co., Ltd.) were laminated on this adhesive layer. Then u...

Embodiment 3

[0106] (Making conductive mesh fabric)

[0107] The monofilament made of polyethylene terephthalate with a diameter of 27 μm (denier 8 dtex) in the warp and the monofilament made of polyethylene terephthalate with a diameter of 27 μm (denier 8 dtex) in the weft are pretreated at 190°C. A net-shaped flat fabric composed of silk and silk with a warp and weft density of 100 threads per inch. Next, calendering was performed at a temperature of 90° C. and a linear pressure of 30 kg / cm. Thereafter, this mesh flat fabric was subjected to electroplating in the same manner as in Example 1. The obtained conductive mesh fabric had a maximum thickness of 28 µm and an opening ratio of 80%.

[0108] (adhesive coating treatment)

[0109] Using a comma direct coater, the gap between the release sheet (SLK-80KCT: manufactured by Sumika Paper Co., Ltd.) and the comma head was adjusted to 60 μm, and the same adhesive coating liquid as in Example 1 was evenly applied. Then, it was made to pas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| contact resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com