Magnetic heavy metal trapping agent and application thereof

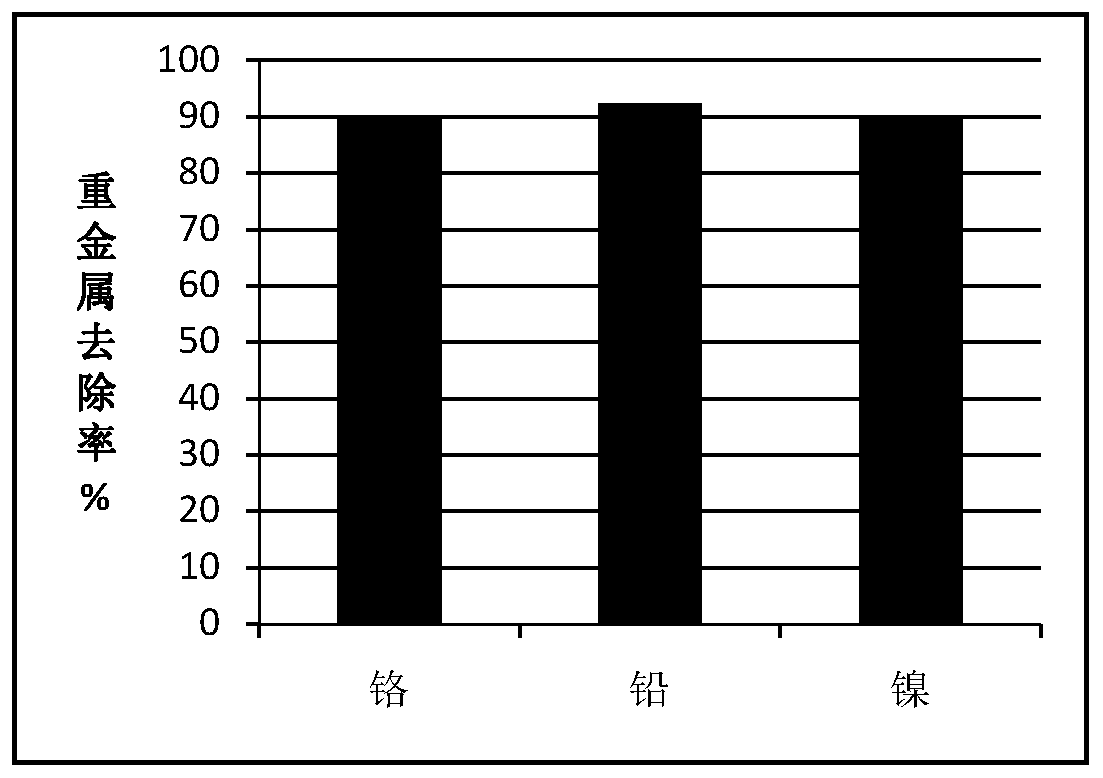

A heavy metal trapping agent and heavy metal technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage treatment, etc., can solve the problems of complex preparation process and high energy consumption, and achieve convenient and simple process, The effect of low energy consumption and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

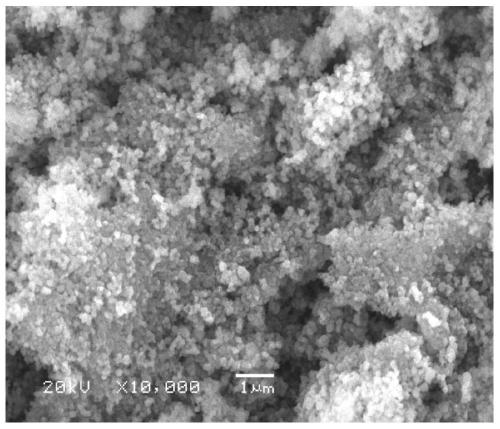

[0031] A magnetic heavy metal collector comprising FeSO in a molar ratio of 1:2 4 Made with sodium thioglycolate.

[0032] The application of the above-mentioned magnetic heavy metal trapping agent in trapping heavy metals comprises the following steps:

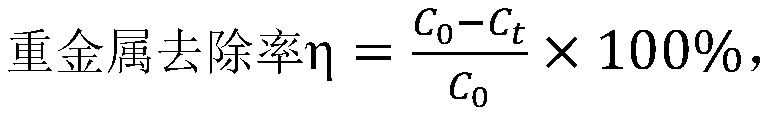

[0033] Take 500mL of pre-configured 100mg / L copper-containing wastewater (about 0.00078mol), and add 0.003mol FeSO 4 Add 0.006mol sodium mercaptoacetate to copper-containing wastewater, and react for 2 hours under the action of a magnetic stirrer at a speed of 300rpm / min. After the reaction, let the solution stand for a period of time to separate the solid and liquid, and use it under the action of an ordinary magnet. Ferrite magnetism realizes solid-liquid separation, and the supernatant is used to measure the residual concentration of heavy metals.

Embodiment 2

[0035] The magnetic heavy metal scavenger and its application in this embodiment are the same as those in Embodiment 1, except that the rotational speed of the magnetic stirrer is replaced by 200 rpm / min.

Embodiment 3

[0037] The magnetic heavy metal scavenger and its application in this embodiment are the same as those in Embodiment 1, except that the rotational speed of the magnetic stirrer is replaced by 400 rpm / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com