A kind of preparation method of ytterbium doped bismuth iridate pyrochlore polycrystalline material

A polycrystalline material and pyrochlore technology, which is applied in the field of preparation of pyrochlore polycrystalline materials, can solve the problems of complex preparation process, compound heterophase, low preparation efficiency, etc. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

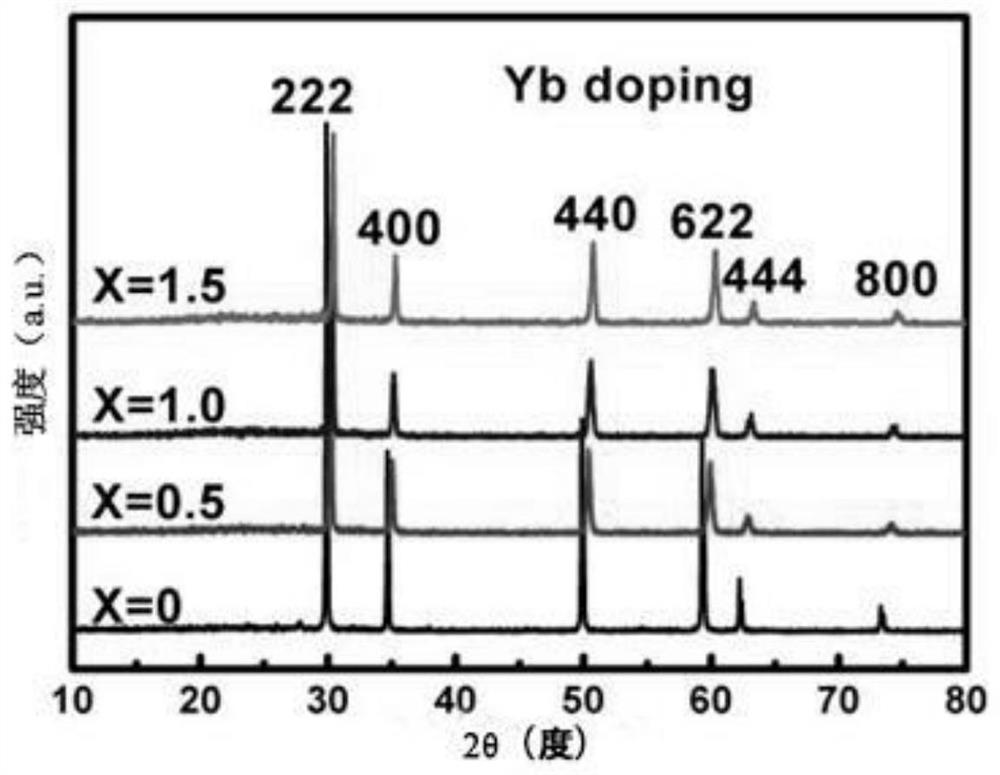

[0034] Yb described in the present invention 3+ The preparation method of doped bismuth iridate pyrochlore polycrystalline material comprises the following steps:

[0035] (1) Change Yb 2 o 3 Powder, Bi 2 o 3 Powder and IrO 2 The first calcination after powder mixing;

[0036] (2) Grinding the mixture calcined for the first time in step (1) and pressing it into a disc, and calcining for the second time;

[0037] (3) Grinding the mixture calcined for the second time in step (2) and pressing it into a disc, and calcining for the third time to obtain Bi 2-x Yb x Ir 2 o 7 Crystal, where 0≤x≤1.5.

[0038] The present invention adopts Yb 2 o 3 Powder, Bi 2 o 3 Powder and IrO 2 Powder blending, three calcinations and two grinding and tableting to prepare Bi 2-x Yb x Ir 2 o 7 crystals. The preparation process of the method is simple, but the preparation efficiency is high.

[0039] In the method of the present invention, in step (1), Yb 2 o 3 Powder, Bi 2 o 3 ...

Embodiment 1

[0058] (1) Change Yb 2 o 3 Powder, Bi 2 o 3 Powder and IrO 2 After the powder is mixed, the first calcination is carried out in a horse-boiling furnace, wherein, Yb 2 o 3 Powder, Bi 2 o 3 Powder and IrO 2 The mass ratio of the powder is 1:1.5:4, the first calcination process is: the temperature in the horse boiling furnace is raised from room temperature to 973.15K, the heating rate is 5K / min, calcined at 973.15K for 12 hours, and then cooled to 473.15K, The cooling rate is 3K / min, and finally cool down to room temperature with the furnace;

[0059] (2) After the mixture calcined for the first time in step (1) is ground with a grinding rod, it is pressed into a disc with a diameter of 1.5cm and a thickness of 1mm with a tablet press under a pressure of 6Mpa for 5 minutes. Carry out the second calcination in the middle, the second calcination process is: the temperature in the horse boiling furnace is warmed up from room temperature to 1223.15K, the heating rate is 3K / ...

Embodiment 2

[0063] (1) Change Yb 2 o 3 Powder, Bi 2 o 3 Powder and IrO 2 After the powder is mixed, the first calcination is carried out in a horse-boiling furnace, wherein, Yb 2 o 3 Powder, Bi 2 o 3 Powder and IrO 2 The mass ratio of the powder is 1:3.5:5, the first calcination process is: the temperature in the horse boiling furnace is raised from room temperature to 950K, the heating rate is 4K / min, calcined at 950K for 14 hours, and then cooled to 473.15K, the cooling rate 2K / min, and finally cooled down to room temperature with the furnace;

[0064] (2) After the mixture calcined for the first time in step (1) is ground with a grinding rod, it is pressed into a disc with a diameter of 1.4cm and a thickness of 1.2mm with a tablet press under a pressure of 8Mpa for 6 minutes. Carry out calcining for the second time in the horse boiling furnace, the second calcining process is: the temperature in the horse boiling furnace is warming up to 1200K by room temperature, and the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com