Method and device for condensing crude vinyl chloride

A crude vinyl chloride and vinyl chloride technology, which is used in steam/steam condensers, solidification, refrigeration and liquefaction, etc., can solve problems such as water shortage, and achieve the effect of alleviating water shortage, improving promotion prospects and solving water shortage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

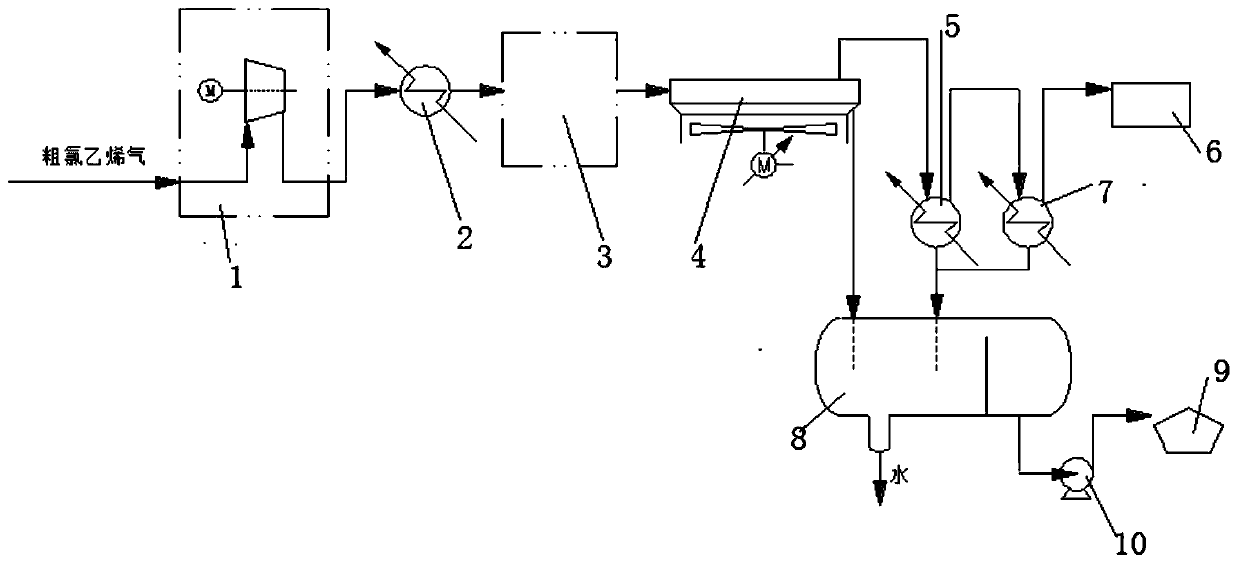

[0039]A method for condensing crude vinyl chloride, comprising a compression step, an after-machine cooling step, a first-stage total condensation step, a second-stage total condensation step, and a tail cooling step, wherein the condensation in the first-stage total condensation step is an air cooling method. The total condenser used in the air cooling method is an air cooler. The pressure of the crude vinyl chloride gas before entering the condensation step is 0.64 or 0.65MPaG, and the temperature is 60 or 65°C. In the optimized scheme, the pressure is 0.645MPaG, and the temperature is 60°C.

[0040] The refined vinyl chloride gas is condensed through the vinyl chloride compressor, the aftercooler, the crude vinyl chloride drying system and the air cooler in turn, and the uncondensed gas enters the second-stage total condenser and the tail cooler for further condensation, and the uncondensed gas enters the tail gas adsorption system for adsorption ; The condensate in the air...

Embodiment 2

[0044] A method for condensing crude vinyl chloride comprises a compression step, an after-machine cooling step, a first-stage total condensation step, a second-stage total condensation step, and a tail cooling step, wherein the condensation in the first-stage total condensation step is air-cooled.

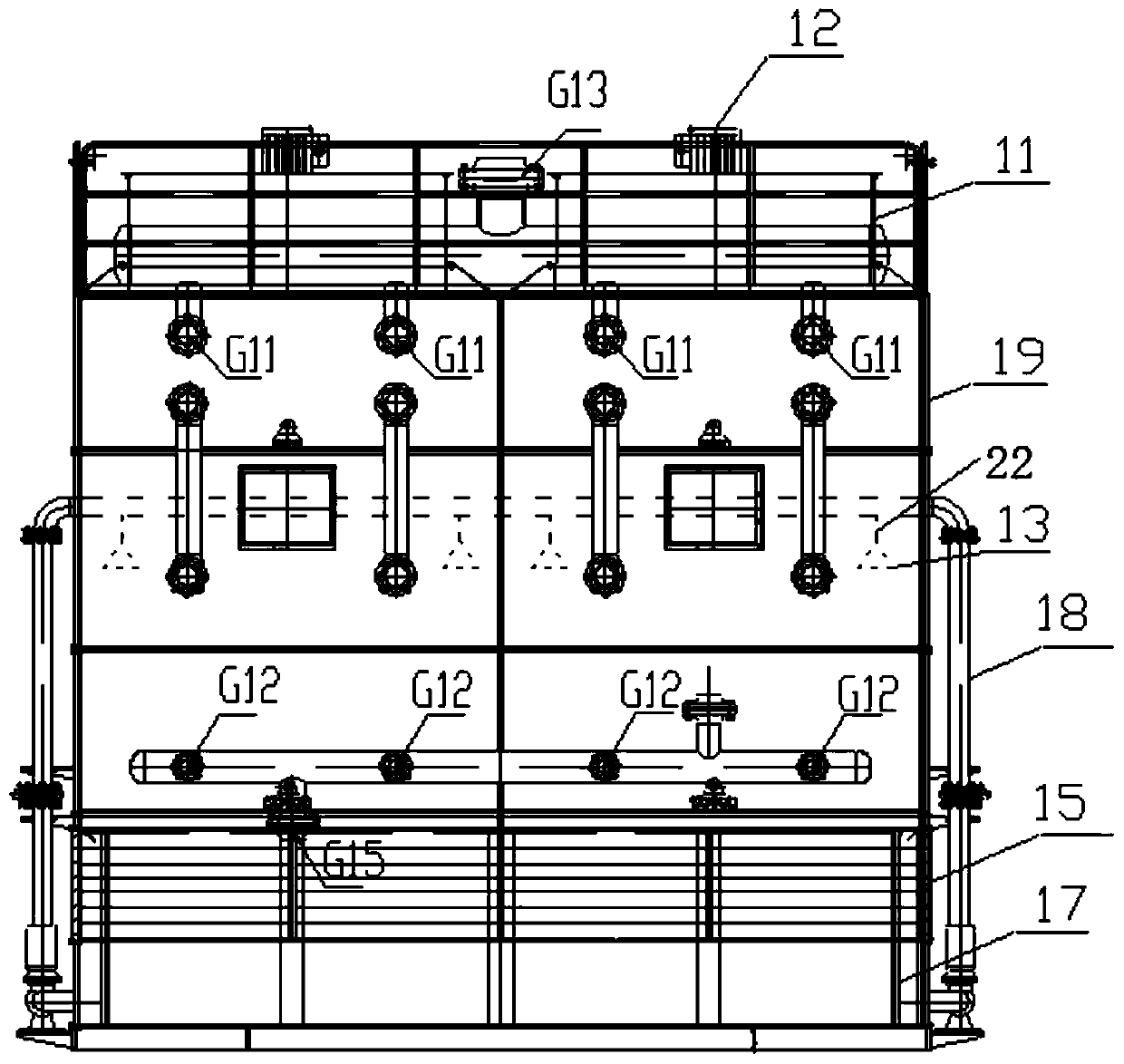

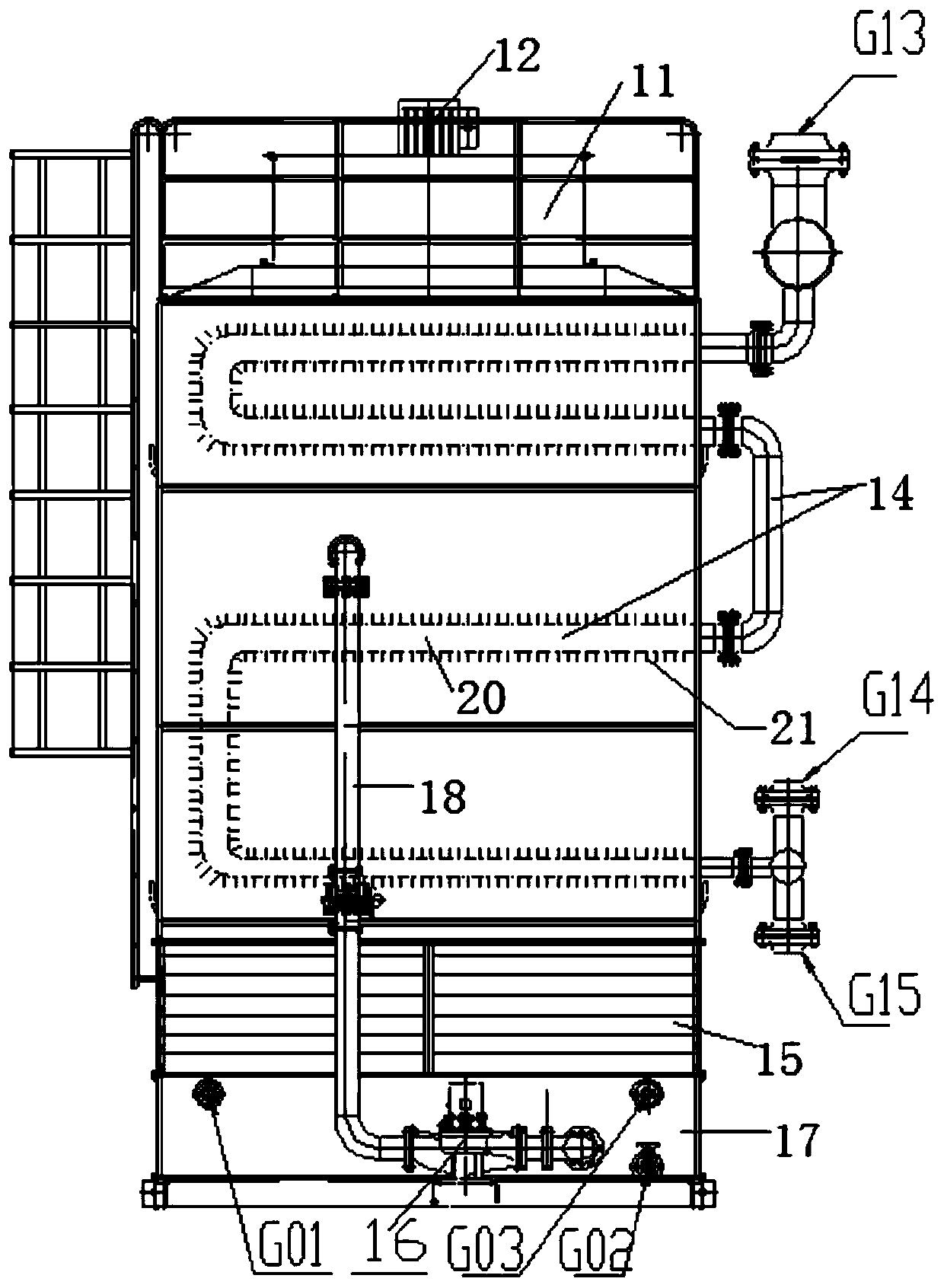

[0045] The total condenser in the air cooling mode is an air cooler with a header fin structure, using a light tube with an outer diameter of 25mm and a fin with a height of 12.5mm. Sprayers are installed on the fins, and cooling coils are installed on the air cooler, which is a special-shaped coil group structure, and the cooling coils are hot-dip galvanized at 475 °C.

[0046] The pressure of the crude vinyl chloride gas before entering the condensation step is 0.645MPaG, and the temperature is 60°C.

[0047] The fan motor of the air cooler adopts a variable frequency motor, and the air cooler is provided with louvers, and a protective net is arranged on the louvers.

[0048] T...

Embodiment 3

[0050] A device for condensing crude vinyl chloride, which is equipped with a vinyl chloride compressor, an aftercooler, a crude vinyl chloride drying system, an air cooler, a first-stage total condenser, a second-stage total condenser, an exhaust gas adsorption system, a tail cooler, and a vinyl chloride storage Tank, liquid-phase vinyl chloride rectification system and pump, vinyl chloride compressor and crude vinyl chloride drying system are connected through after-machine cooler, crude vinyl chloride drying system is connected with one-stage total condenser, and one-stage total condenser is respectively connected with The tank is connected to the second-stage total condenser, and the second-stage total condenser is also connected to the vinyl chloride storage tank and one end of the tail cooler; the other end of the tail cooler is connected to the exhaust gas adsorption system, and the other end of the tail cooler is connected to the second-stage total condenser and the viny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com