A surface anti-oxidation treatment method of low demagnetization rate NdFeB permanent magnet powder

A treatment method and anti-oxidation technology, applied in chemical instruments and methods, hybrid methods, permanent magnet manufacturing, etc., can solve problems such as reducing product stability and reliability, limiting the scope of application, affecting the magnetic performance of magnets, etc. Effects of oxidation and corrosion resistance, improvement of film quality, and improvement of oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

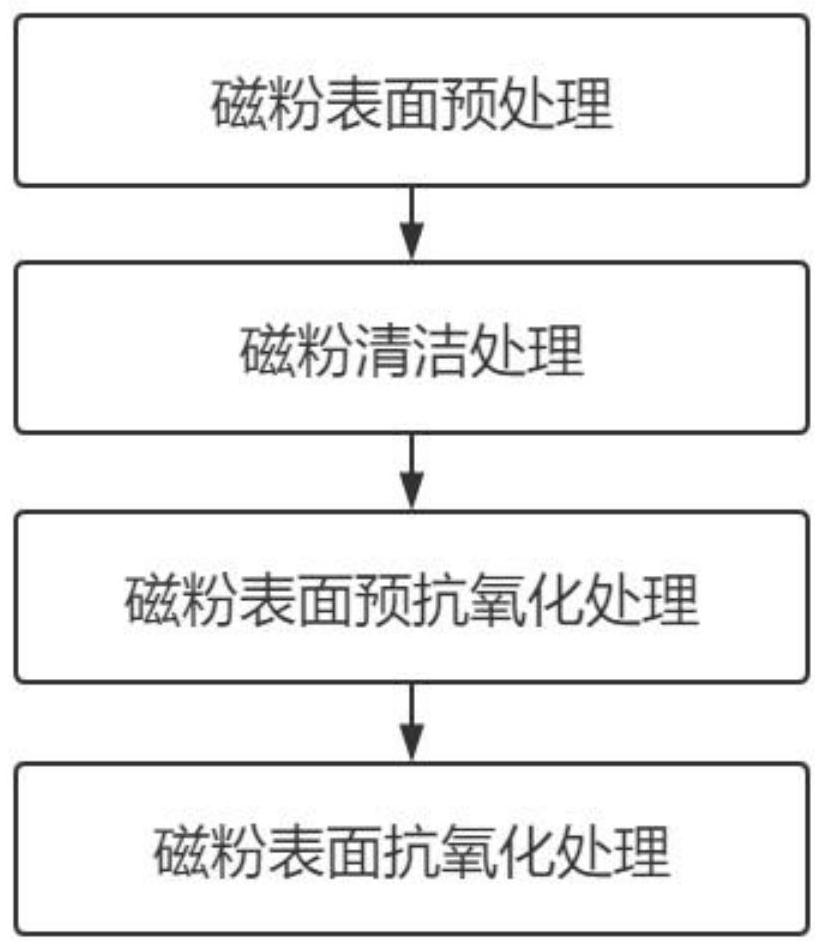

[0039] see figure 1 , a surface anti-oxidation treatment method of low demagnetization rate NdFeB permanent magnet powder, comprising the following steps:

[0040] S1: Magnetic powder surface pretreatment: The magnetic powder to be treated is treated by mechanical sandblasting to improve the surface friction of the magnetic powder;

[0041] S2: Magnetic powder cleaning treatment: put the magnetic powder treated in S1 into distilled water for ultrasonic cleaning, remove the stains on the surface of the magnetic powder, filter and vacuum dry in a drying oven, and keep the drying temperature at 45-60°C;

[0042] S3: Pre-oxidation treatment on the surface of the magnetic powder: immerse the magnetic powder obtained in S2 in the silane coupling agent, take it out after immersion for 1-2 hours, filter it and put it back in the oven for vacuum drying, the drying temperature is kept at 45-60°C, spare;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com