Flexible electrolyte film with deformation self-adaption and self-repairing functions and preparation method and application thereof

A flexible electrolyte and self-repairing technology, applied in the fields of composite electrolytes, electrolyte battery manufacturing, non-aqueous electrolyte batteries, etc., can solve the problems of poor mechanical properties of electrolyte content, low battery energy density, and large proportion of inactive substances. Good stretchable recovery performance, strong deformation adaptability, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

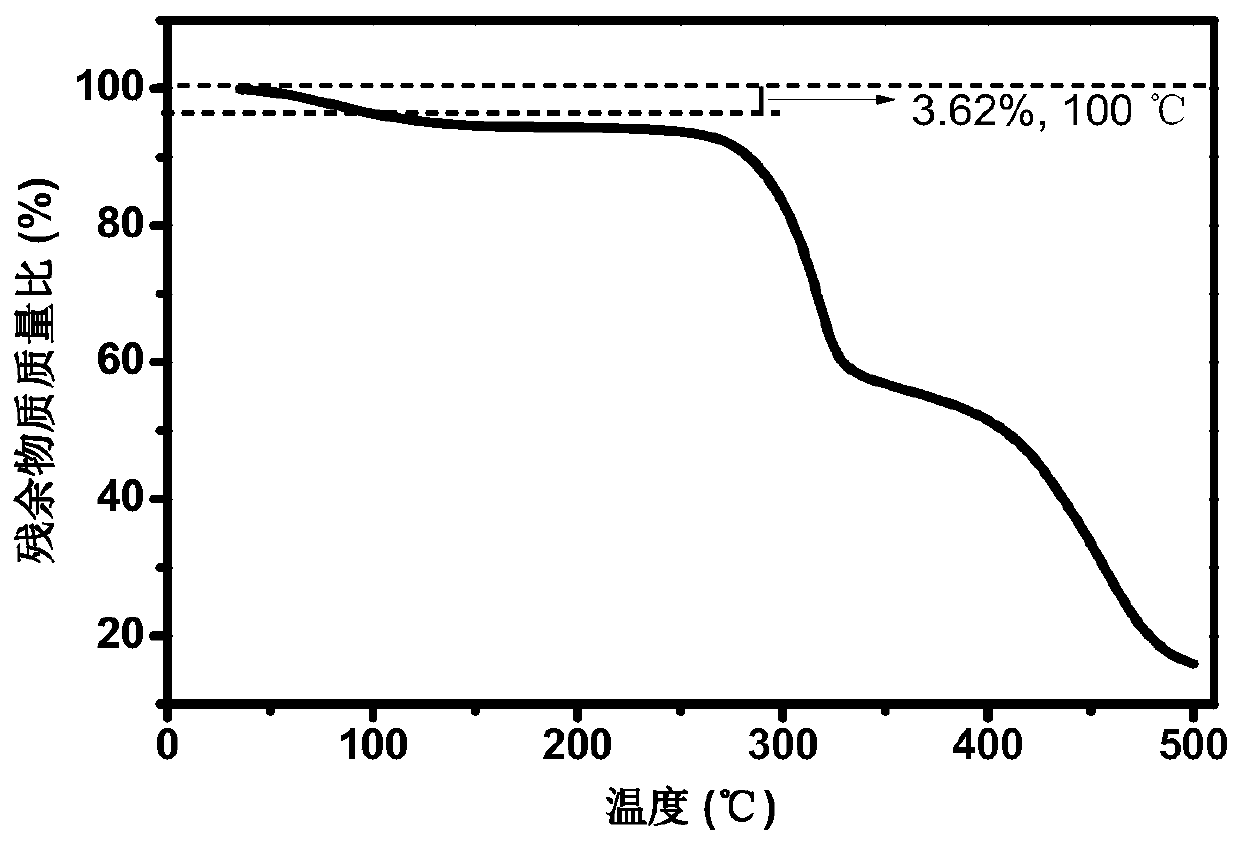

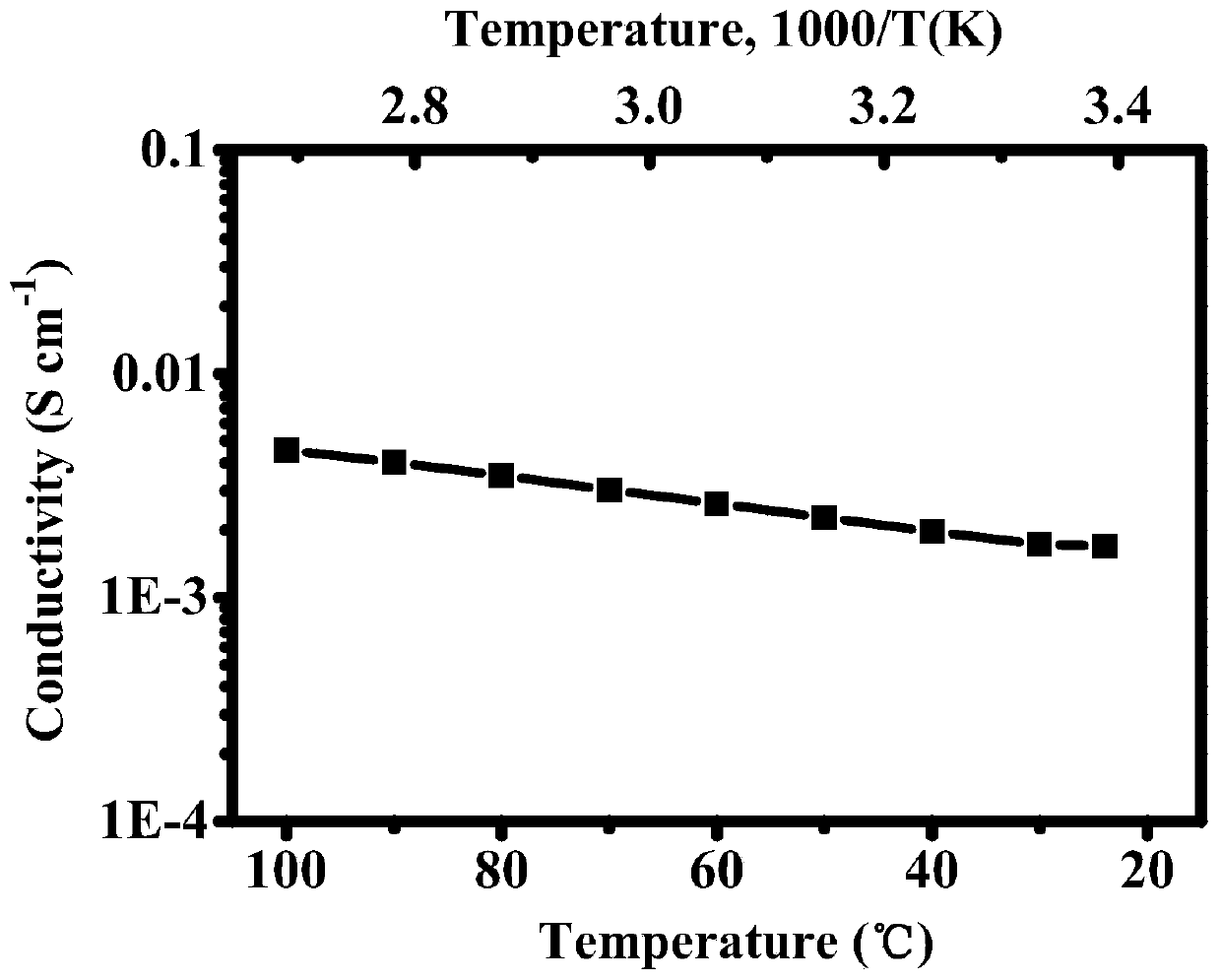

[0031] The preparation method of the flexible electrolyte membrane with deformation self-adaptive and self-healing described in this embodiment, its steps and process conditions are as follows:

[0032] Step 1: Configure the precursor solution

[0033] It is 5.5% poly n-butyl acrylate-silane copolymer elastic emulsion with deionized water preparation solid content, preparation solid content is 1% sodium carboxymethyl cellulose solution; Then the mass ratio by solid content is 2:3: Weigh poly(n-butyl acrylate-silane copolymer) elastic emulsion, sodium carboxymethyl cellulose solution, polyether F127 and LiFSI hygroscopic lithium salt in a container at a ratio of 1:5, stir magnetically for 12 hours, and wait for the components to mix uniformly Obtain the precursor solution for later use.

[0034] Step 2: Film Formation

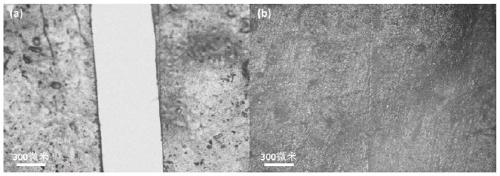

[0035] The precursor solution obtained in step 1 was coated on the glass substrate by scraping, and then dried at 60°C, and then the electrolyte membrane was ...

Embodiment 2

[0040]The steps and process conditions of the preparation method of the flexible electrolyte membrane with deformation self-adaptive and self-healing described in this embodiment are as follows:

[0041] Step 1: Configure the precursor solution

[0042] Prepare a poly(n-butyl acrylate-silane) copolymer elastic emulsion with a solid content of 5.5% with deionized water, prepare a sodium carboxymethyl cellulose solution with a solid content of 3%; then press the solid content in a mass ratio of 3:5:1 : 4 Weigh poly n-butyl acrylate-silane copolymer elastic emulsion, sodium carboxymethyl cellulose solution, polyether F127 and hygroscopic lithium salt LiNO 3 In the container, stir magnetically for 12 hours, and obtain the precursor solution after the components are evenly mixed, and set aside.

[0043] Step 2: Same as Example 1

[0044] Step 3: Post-processing

[0045] Cut the white film obtained in step 2 into a rectangular sheet with a diameter of 35 mm in length and a width ...

Embodiment 3

[0048] The steps and process conditions of the preparation method of the flexible electrolyte membrane with deformation self-adaptive and self-healing described in this embodiment are as follows:

[0049] Step 1: Configure the precursor solution

[0050] Prepare a poly(n-butyl acrylate-silane) copolymer elastic emulsion with a solid content of 5.5% with deionized water, prepare a sodium carboxymethyl cellulose solution with a solid content of 2%; then press the solid content in a mass ratio of 2:3:1 : 6 Weigh poly n-butyl acrylate-silane copolymer elastic emulsion, sodium carboxymethyl cellulose solution, polyether F127 and easy moisture-absorbing lithium salt LiTFSI in a container, stir magnetically for 12 hours, and obtain after the components are mixed evenly Precursor solution, spare.

[0051] Step 2: Same as Example 1.

[0052] Step 3: Post-processing

[0053] The white film obtained in step 2 was cut into discs with a diameter of 16 mm according to the required requir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sub-conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com