Flexible electrolyte membrane with deformation self-adaptive self-healing and its preparation method and application

A flexible electrolyte and self-repairing technology, which is applied in the direction of composite electrolyte, electrolyte storage battery manufacturing, non-aqueous electrolyte storage battery, etc., can solve the problems of poor mechanical properties of electrolyte content, low battery energy density, large proportion of inactive substances, etc., to achieve Good self-healing, strong deformation adaptability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

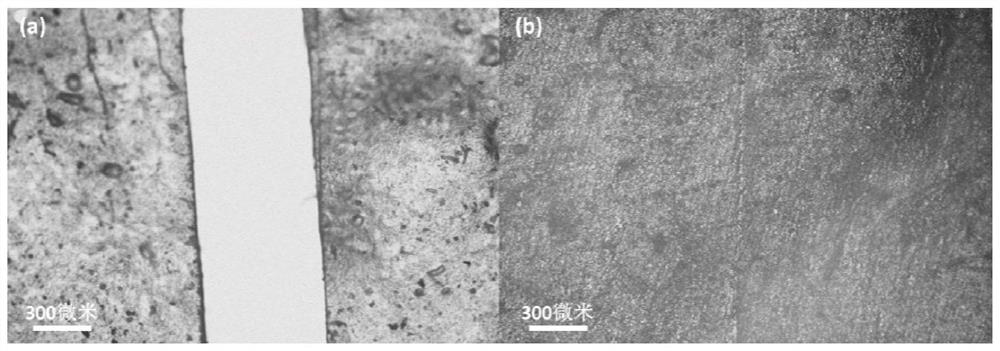

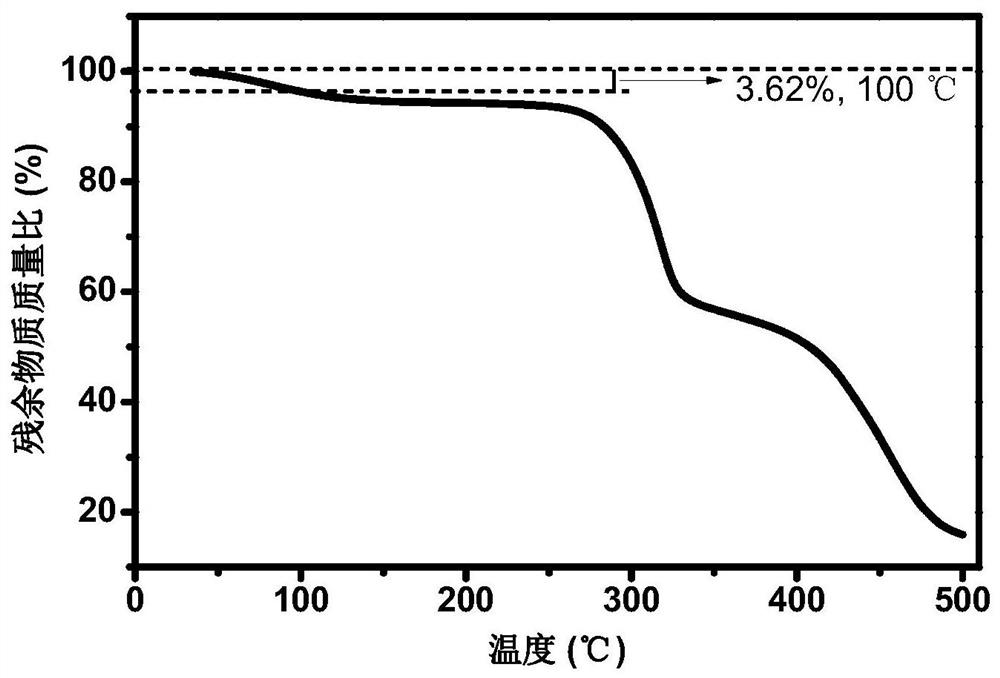

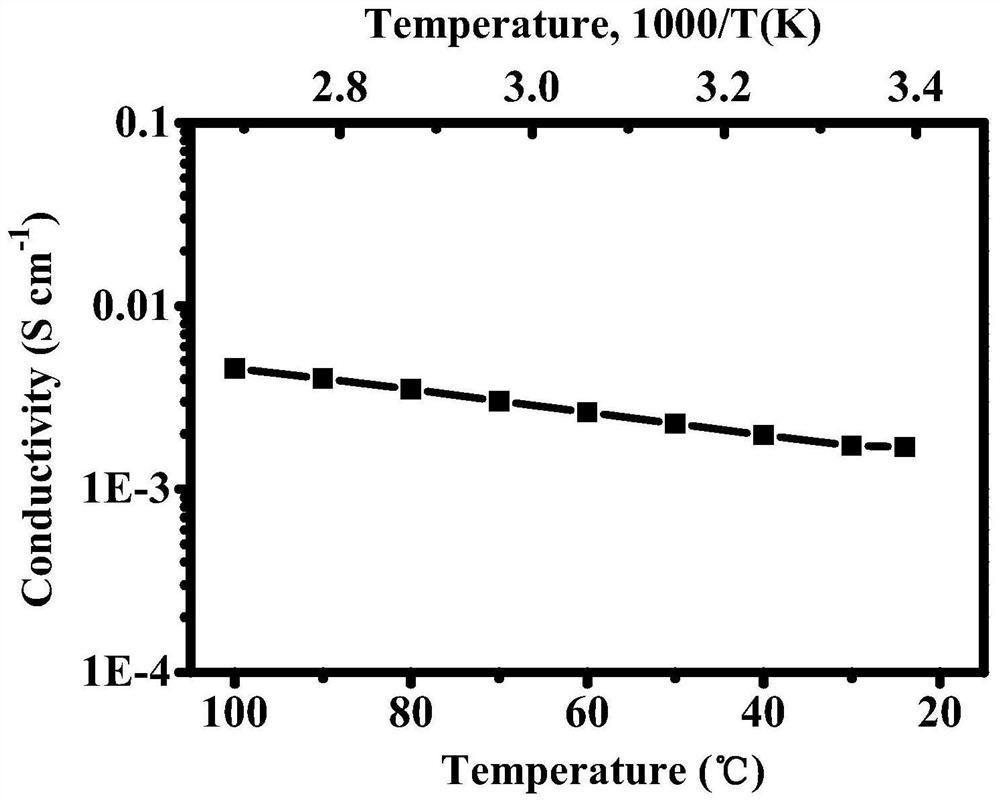

[0031] The preparation method of the flexible electrolyte membrane with deformation self-adaptive and self-healing described in this embodiment, its steps and process conditions are as follows:

[0032] Step 1: Configure the precursor solution

[0033] It is 5.5% poly n-butyl acrylate-silane copolymer elastic emulsion with deionized water preparation solid content, preparation solid content is 1% sodium carboxymethyl cellulose solution; Then the mass ratio by solid content is 2:3: Weigh poly(n-butyl acrylate-silane copolymer) elastic emulsion, sodium carboxymethyl cellulose solution, polyether F127 and LiFSI hygroscopic lithium salt in a container at a ratio of 1:5, stir magnetically for 12 hours, and wait for the components to mix uniformly Obtain the precursor solution for later use.

[0034] Step 2: Film Formation

[0035] The precursor solution obtained in step 1 was coated on the glass substrate by scraping, and then dried at 60°C, and then the electrolyte membrane was ...

Embodiment 2

[0040]The steps and process conditions of the preparation method of the flexible electrolyte membrane with deformation self-adaptive and self-healing described in this embodiment are as follows:

[0041] Step 1: Configure the precursor solution

[0042] Prepare a poly(n-butyl acrylate-silane) copolymer elastic emulsion with a solid content of 5.5% with deionized water, prepare a sodium carboxymethyl cellulose solution with a solid content of 3%; then press the solid content in a mass ratio of 3:5:1 : 4 Weigh poly n-butyl acrylate-silane copolymer elastic emulsion, sodium carboxymethyl cellulose solution, polyether F127 and hygroscopic lithium salt LiNO 3 In the container, stir magnetically for 12 hours, and obtain the precursor solution after the components are evenly mixed, and set aside.

[0043] Step 2: Same as Example 1

[0044] Step 3: Post-processing

[0045] Cut the white film obtained in step 2 into a rectangular sheet with a diameter of 35 mm in length and a width ...

Embodiment 3

[0048] The steps and process conditions of the preparation method of the flexible electrolyte membrane with deformation self-adaptive and self-healing described in this embodiment are as follows:

[0049] Step 1: Configure the precursor solution

[0050] Prepare a poly(n-butyl acrylate-silane) copolymer elastic emulsion with a solid content of 5.5% with deionized water, prepare a sodium carboxymethyl cellulose solution with a solid content of 2%; then press the solid content in a mass ratio of 2:3:1 : 6 Weigh poly n-butyl acrylate-silane copolymer elastic emulsion, sodium carboxymethyl cellulose solution, polyether F127 and easy moisture-absorbing lithium salt LiTFSI in a container, stir magnetically for 12 hours, and obtain after the components are mixed evenly Precursor solution, spare.

[0051] Step 2: Same as Example 1.

[0052] Step 3: Post-processing

[0053] The white film obtained in step 2 was cut into discs with a diameter of 16 mm according to the required requir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com