Alkaline aqueous electrolyte for aluminum-air battery and application of alkaline aqueous electrolyte

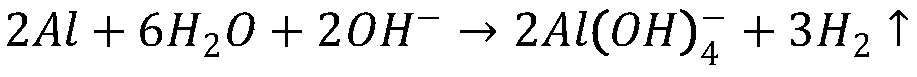

A water-based electrolyte and aluminum-air battery technology, applied in the direction of alkaline electrolyte, aqueous electrolyte, electrolyte, etc., can solve the problems of complicated electrochemical reactions, accelerated electrolyte gelation, accelerated battery failure, etc., to achieve improved electrochemical performance performance, reducing self-corrosion, and reducing the effect of hydrogen evolution self-corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

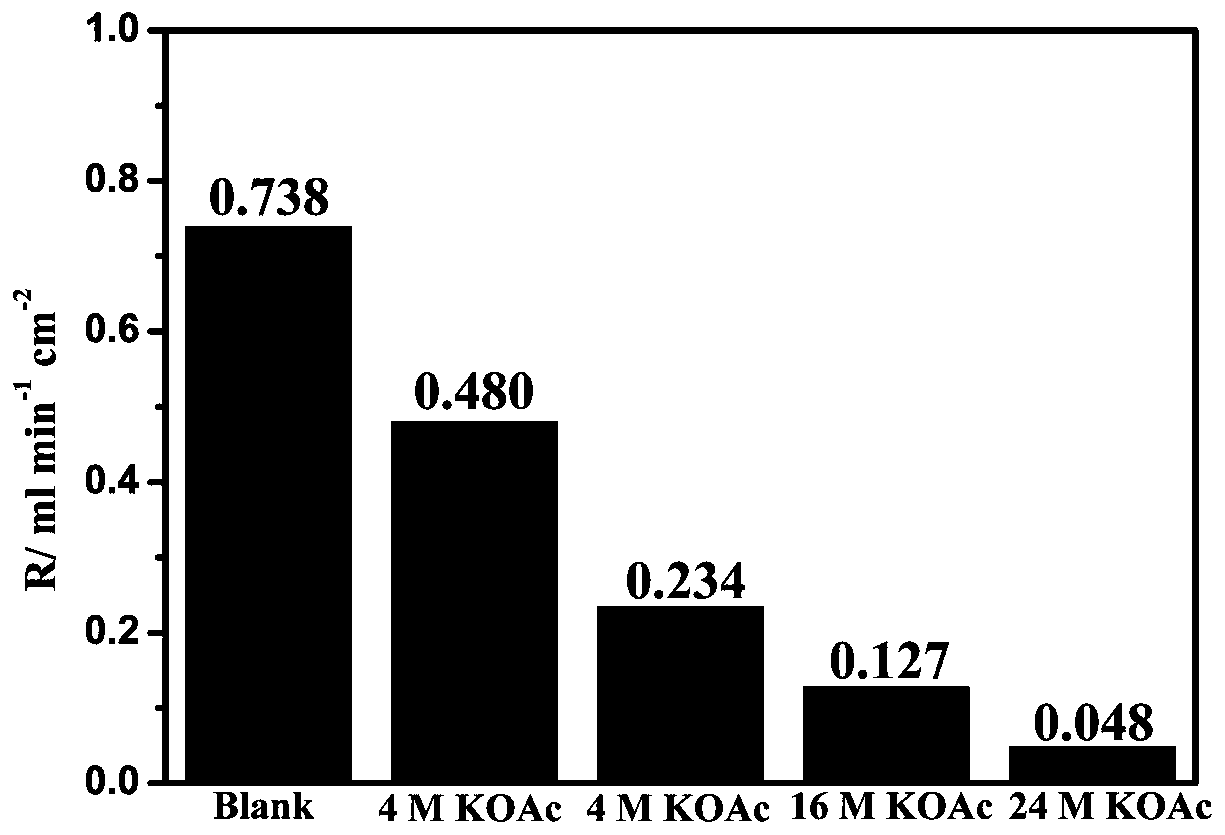

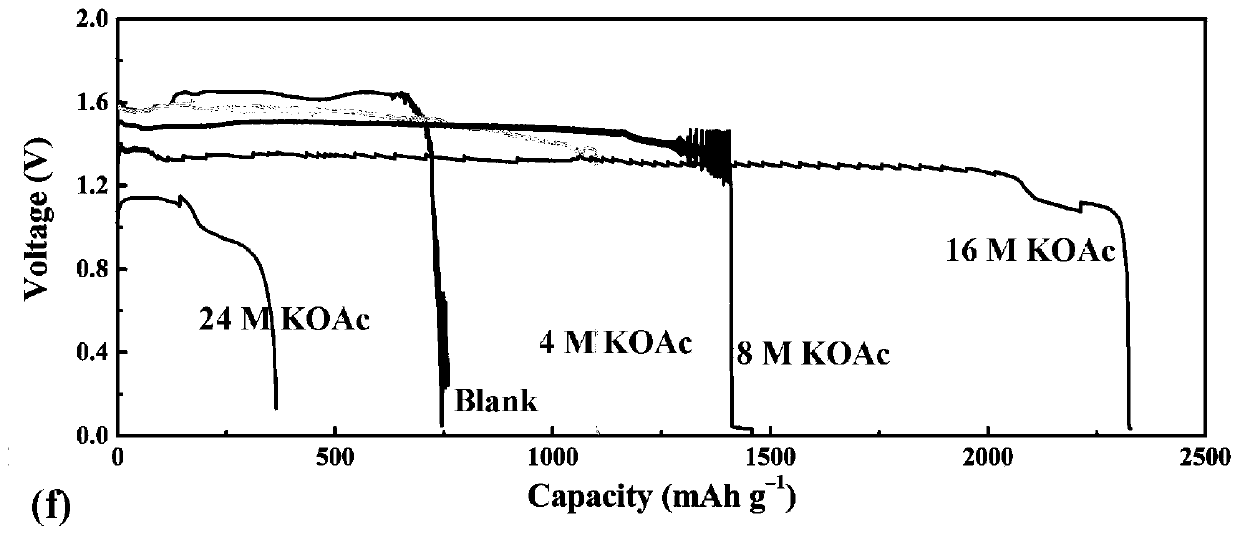

[0039] The high-concentration salt additive of the present embodiment is potassium acetate of 4mol / kg.

[0040] The aluminum-air battery electrolyte of this embodiment includes KOH, potassium acetate, and water; the mass molar concentration of potassium acetate in the electrolyte is 4 mol / kg, and the concentration of KOH is 4 mol / L.

[0041] The preparation method of the aluminum-air battery electrolyte of the present embodiment comprises the following steps:

[0042] Prepare a potassium hydroxide solution with a concentration of 4 mol / L, cool down to room temperature, then add potassium acetate in the prescribed amount into the potassium hydroxide solution, stir and sonicate until completely dissolved.

[0043] The aluminum-air battery of this embodiment uses the above-mentioned electrolyte solution for the aluminum-air battery.

Embodiment 2

[0045] The high concentration salt additive of embodiment is the potassium acetate of 8mol / kg.

[0046] The aluminum-air battery electrolyte of this embodiment includes KOH, potassium acetate, and water; the mass molar concentration of potassium acetate in the electrolyte is 8 mol / kg, and the concentration of KOH is 4 mol / L.

[0047] The preparation method of the aluminum-air battery electrolyte of the present embodiment comprises the following steps:

[0048] Prepare a potassium hydroxide solution with a concentration of 4 mol / L, cool down to room temperature, then add potassium acetate in the prescribed amount into the potassium hydroxide solution, stir and sonicate until completely dissolved.

[0049] The aluminum-air battery of this embodiment uses the above-mentioned electrolyte solution for the aluminum-air battery.

Embodiment 3

[0051] The high concentration salt additive of embodiment is the potassium acetate of 16mol / kg.

[0052] The aluminum-air battery electrolyte of this embodiment includes KOH, potassium acetate, and water; the mass molar concentration of potassium acetate in the electrolyte is 16 mol / kg, and the concentration of KOH is 4 mol / L.

[0053] The preparation method of the aluminum-air battery electrolyte of the present embodiment comprises the following steps:

[0054] Prepare a potassium hydroxide solution with a concentration of 4 mol / L, cool down to room temperature, then add potassium acetate in the prescribed amount into the potassium hydroxide solution, stir and sonicate until completely dissolved.

[0055] The aluminum-air battery of this embodiment uses the above-mentioned electrolyte solution for the aluminum-air battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com