Four-direct-current-motor parallel current hysteresis fault-tolerant control method and control system

A DC motor, fault-tolerant control technology, applied in the direction of DC motor rotation control, DC motor speed/torque control, excitation or armature current control, etc., can solve problems such as equipment not working properly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

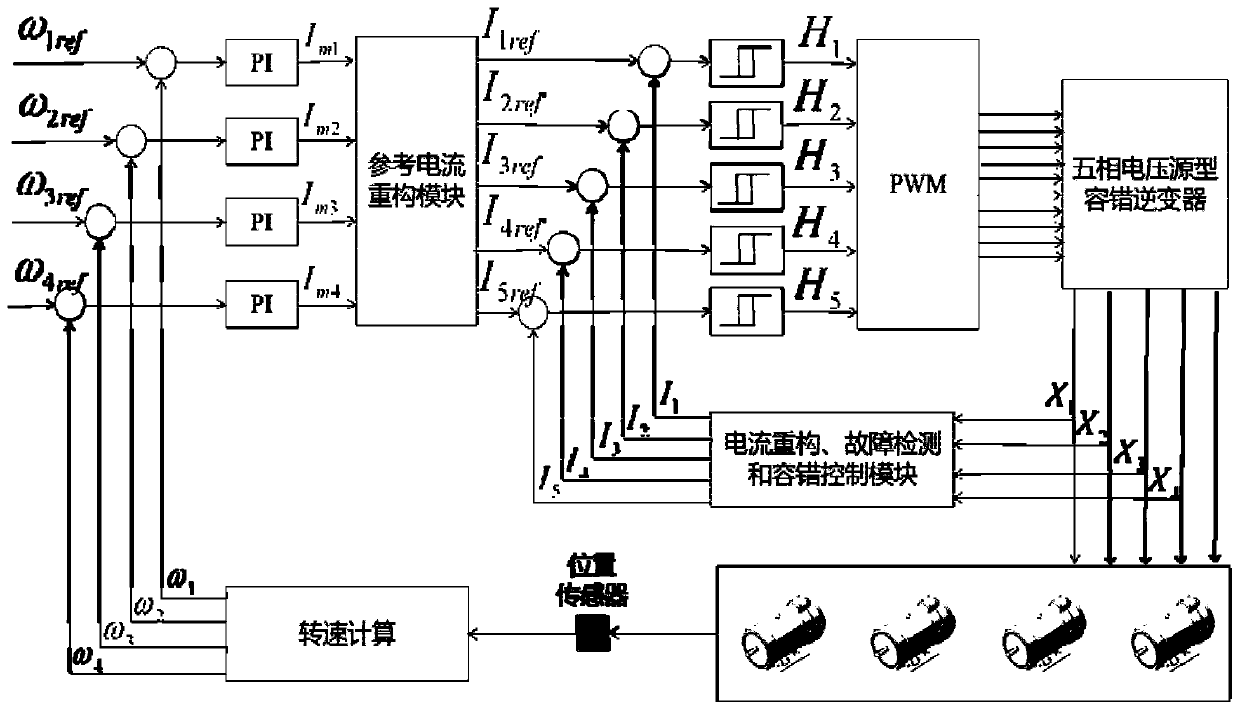

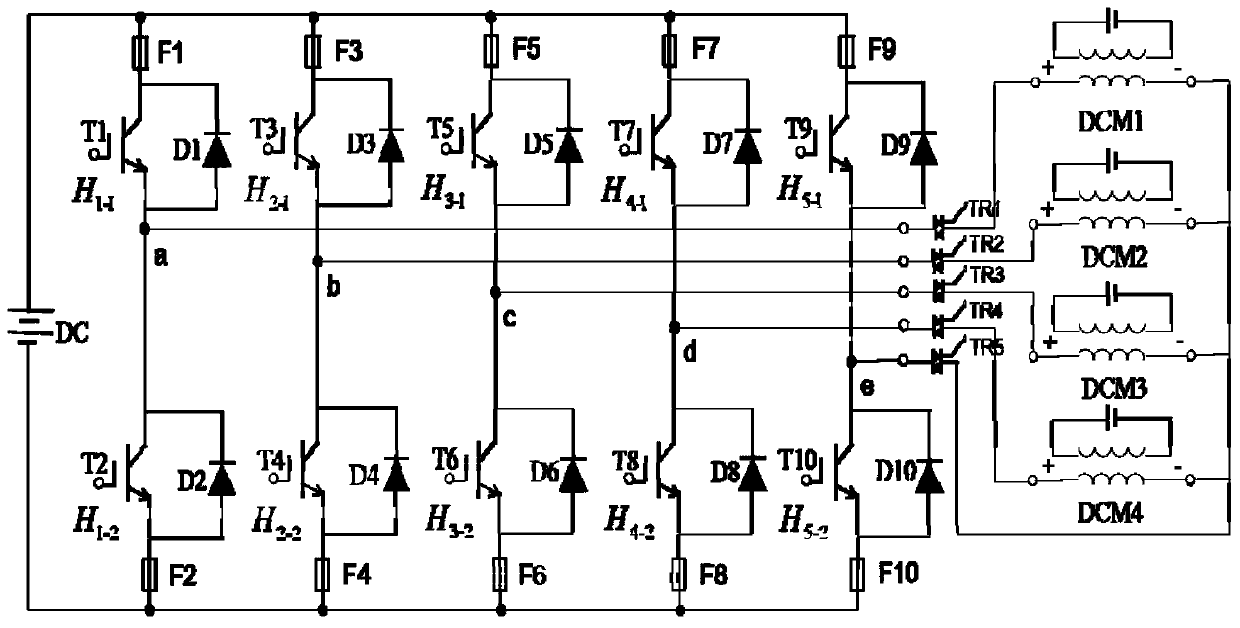

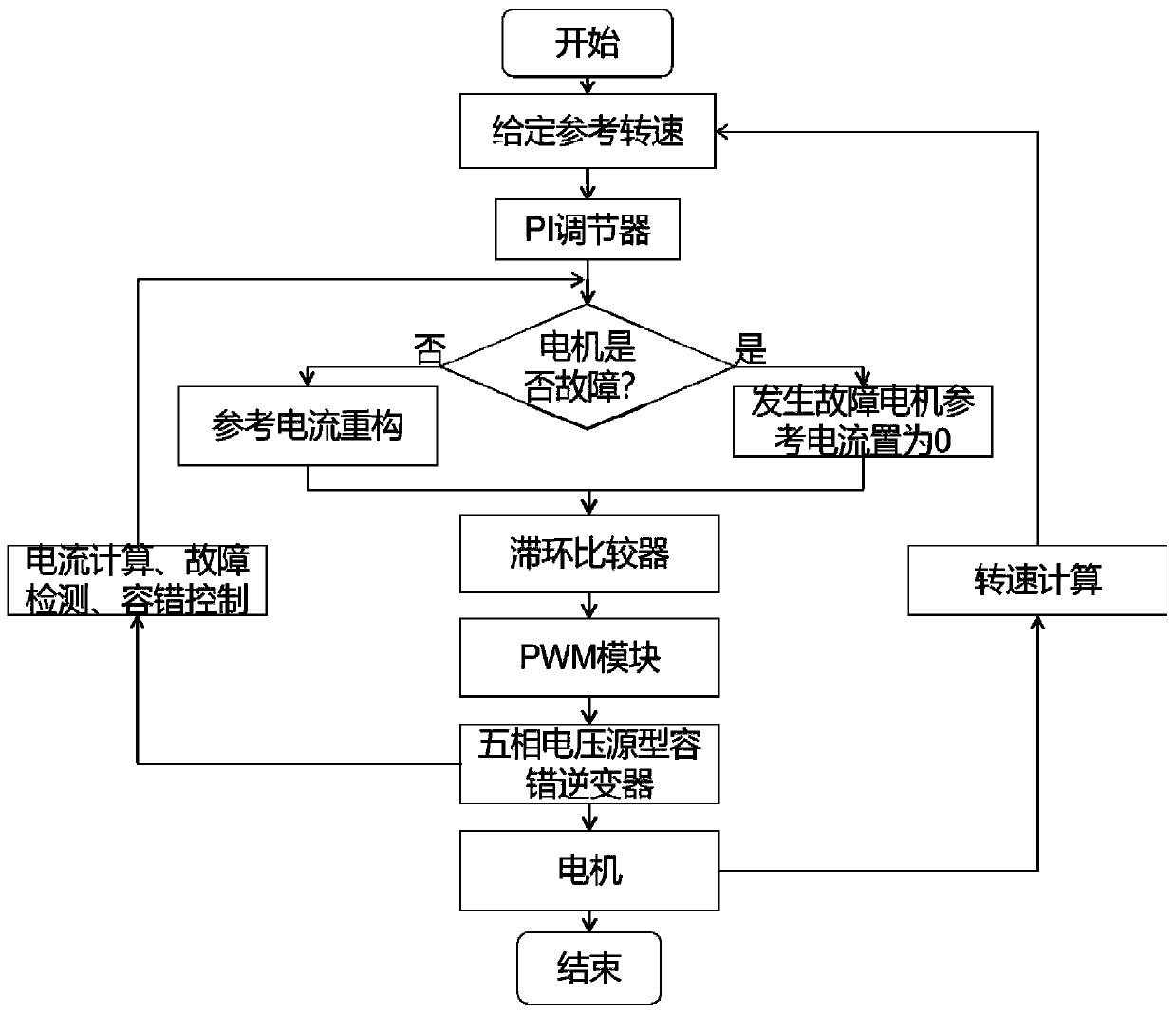

[0144] Such as figure 1 and 2 As shown, a current hysteresis fault-tolerant control system of four DC motors connected in parallel in the present invention includes 4 DC motors arranged in parallel, 4 PI controllers, a reference current reconstruction module, and 5 hysteresis comparators, And a PWM module, and a five-phase voltage source fault-tolerant inverter, and a current reconstruction, fault detection and fault-tolerant control module, and a speed calculation module, and a position sensor, and a current detection sensor; the input terminal of the reference current reconstruction module Connect with 4 PI controllers respectively, the output terminal of the reference current reconstruction module is connected with the input terminals of 5 hysteresis comparators respectively; the input terminal of PWM module is connected with the output terminals of 5 hysteresis comparators respectively, and the PWM module The output end of the output terminal is connected to the five-phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com