Preparation method and application of bismuth-titanium-iron oxide chloride photocatalytic material

A technology of photocatalytic materials and oxychlorides, which is applied in the field of photocatalytic material synthesis technology, can solve the problems of wide band gap, high electron-hole recombination rate, and restriction of photocatalytic activity, and achieve small band gap value and hole The effect of low recombination rate and wide response range of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of bismuth titanium iron oxychloride photocatalytic material, comprising the steps of:

[0030] The first step is to prepare bismuth oxychloride nanosheets: Weigh 2 mmol of bismuth nitrate pentahydrate and add it to 20 ml of ethylene glycol, stir with a magnetic stirrer to fully dissolve it, and record it as solution a. The stirring speed of the magnetic stirrer is 10-60 r / min; weigh 2 mmol potassium chloride and dissolve it in 10 ml distilled water, and record it as solution b; add solution b dropwise to solution a at a rate of 1-2 drops per second, and stir magnetically at room temperature for 1 h, stirring at a speed of 10-60 r / min, then centrifugally washing with distilled water at a centrifugal washing speed of 5000-9000rpm, putting the cleaned sample in an oven at 80°C and drying for 12 h to obtain bismuth oxychloride nanosheets;

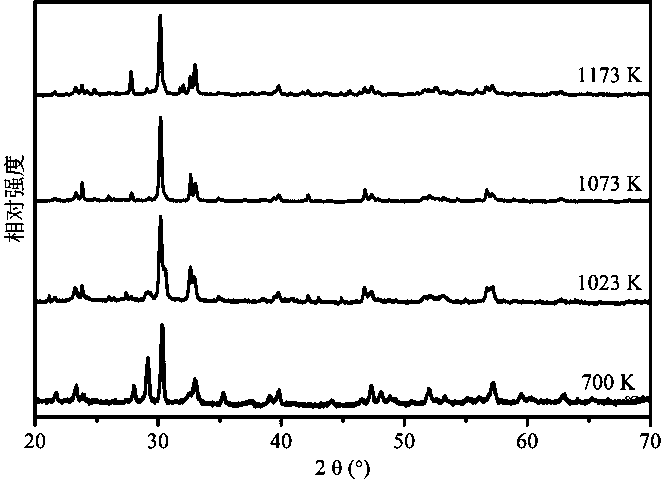

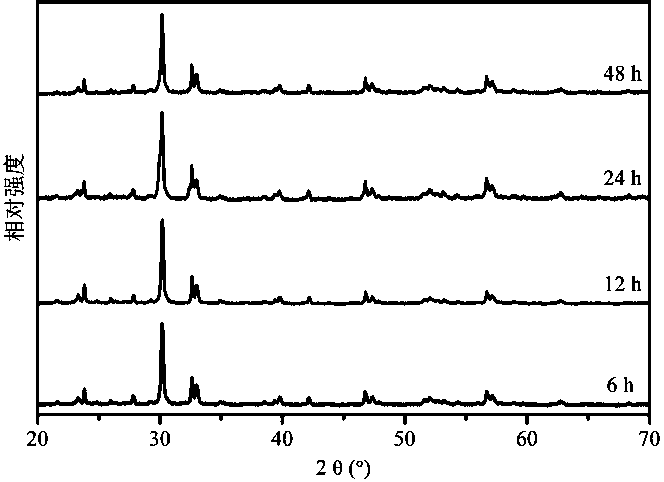

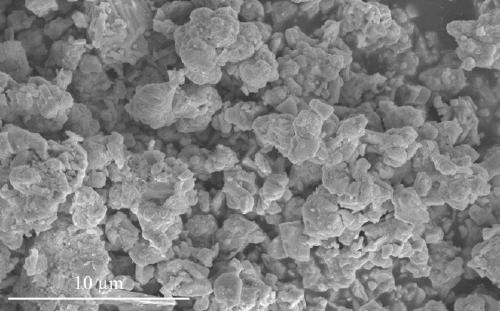

[0031] The second step is to prepare bismuth titanium iron oxychloride: weigh 3 mmol bismuth oxide, 2 mmol titani...

Embodiment 2

[0034] A preparation method and application of a bismuth titanium iron oxychloride photocatalytic material, comprising the following steps:

[0035] The first step is to prepare bismuth oxychloride nanosheets: Weigh 2 mmol of bismuth nitrate pentahydrate and add it to 20 ml of ethylene glycol, stir with a magnetic stirrer to fully dissolve it, and record it as solution a. The stirring speed of the magnetic stirrer is 10-60 r / min; weigh 2 mmol potassium chloride and dissolve it in 10 ml distilled water, and record it as solution b; add solution b dropwise to solution a at a rate of 1-2 drops per second, and stir magnetically at room temperature for 1 h, stirring at a speed of 10-60 r / min, then centrifugally washing with distilled water at a centrifugal washing speed of 5000-9000rpm, putting the cleaned sample in an oven at 80°C and drying for 12 h to obtain bismuth oxychloride nanosheets;

[0036] The second step is to prepare bismuth titanium iron oxychloride: Weigh 3 mmol bis...

Embodiment 3

[0039] A preparation method and application of a bismuth titanium iron oxychloride photocatalytic material, comprising the following steps:

[0040] The first step is to prepare bismuth oxychloride nanosheets: Weigh 2 mmol of bismuth nitrate pentahydrate and add it to 20 ml of ethylene glycol, stir with a magnetic stirrer to fully dissolve it, and record it as solution a. The stirring speed of the magnetic stirrer is 10-60 r / min; weigh 2 mmol potassium chloride and dissolve it in 10 ml distilled water, and record it as solution b; add solution b dropwise to solution a at a rate of 1-2 drops per second, and stir magnetically at room temperature for 1 h, stirring at a speed of 10-60 r / min, then centrifugally washing with distilled water at a centrifugal washing speed of 5000-9000rpm, putting the cleaned sample in an oven at 80°C and drying for 12 h to obtain bismuth oxychloride nanosheets;

[0041] The second step is to prepare bismuth titanium iron oxychloride: Weigh 3 mmol bis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com