Rust-proof anti-fog PE shrink film and processing method thereof

A processing method and technology of shrink film, applied in chemical instruments and methods, flexible coverings, packaging, etc., can solve the problem of affecting the surface state of shrink film and heat-sealing anti-rust performance, unfavorable for the safe storage of packaged objects, and affecting the packaging Material quality and other issues, to achieve excellent anti-fog performance, improve anti-rust and anti-fog performance, and excellent anti-rust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-10

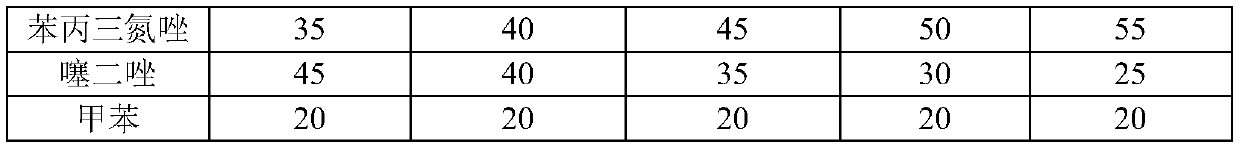

[0038] According to the dosage shown in Table 1, benzotriazole and thiadiazole are diluted in proportion with toluene to prepare antirust mother liquor, respectively to obtain antirust mother liquor 1-5; according to the dosage shown in Table 2, each The antioxidants in the amounts shown in the preparation examples were added to each antirust mother liquor and stirred evenly, and sodium molybdate was added and stirred evenly to obtain the antirust agents of Preparation Examples 1-10 respectively.

[0039] The dosage of each raw material of table 1 antirust mother liquor 1-5 (unit: g)

[0040]

[0041]

[0042] Each raw material dosage (unit: g) of the antirust agent of table 2 preparation example 1-10

[0043]

Embodiment 1

[0049] An anti-rust and anti-fog PE shrink film, which sequentially includes an outer layer, a middle layer and an inner layer from the outside to the inside, and is processed through the following steps:

[0050] (1) According to the composition and dosage in Table 3, prepare the raw materials of the inner layer, middle layer and outer layer respectively, add the raw materials of each layer into the corresponding mixer and stir for 15 minutes, and send them to the three-layer co-extrusion blown film unit. Extrude in corresponding three extruders; Wherein, the antirust agent of middle layer and inner layer selects the antirust agent of Preparation Example 1, the compatibilizer polysiloxane-polyolefin copolymer in each layer polysiloxane The weight percentage of alkane unit is 21%; the barrel temperature of the three extruders is controlled to be 25°C in zone I, 115°C in zone II, 150°C in zone III, 155°C in zone IV, 155°C in zone V, and 155°C in zone VI. Zone 155°C, machine hea...

Embodiment 2-10

[0053] The antirust and antifog PE shrink film of embodiment 2-10 and embodiment 1, processing technology is the same, and the difference is that the antirust agent of middle layer and inner layer selects the antirust agent of preparation example 2-10 respectively, and the raw material types of other layers And dosage is identical with embodiment 1, sees shown in table 3 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com