Shaft hole matched thermophilic anaerobic single-chamber microbial power generation device and manufacturing method thereof

A microbial power generation, thermophilic anaerobic technology, applied in the field of electrical devices, can solve the problems of low electron transfer efficiency, low oxygen reduction activity, etc., and achieve considerable application effects, low movement resistance, and battery saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

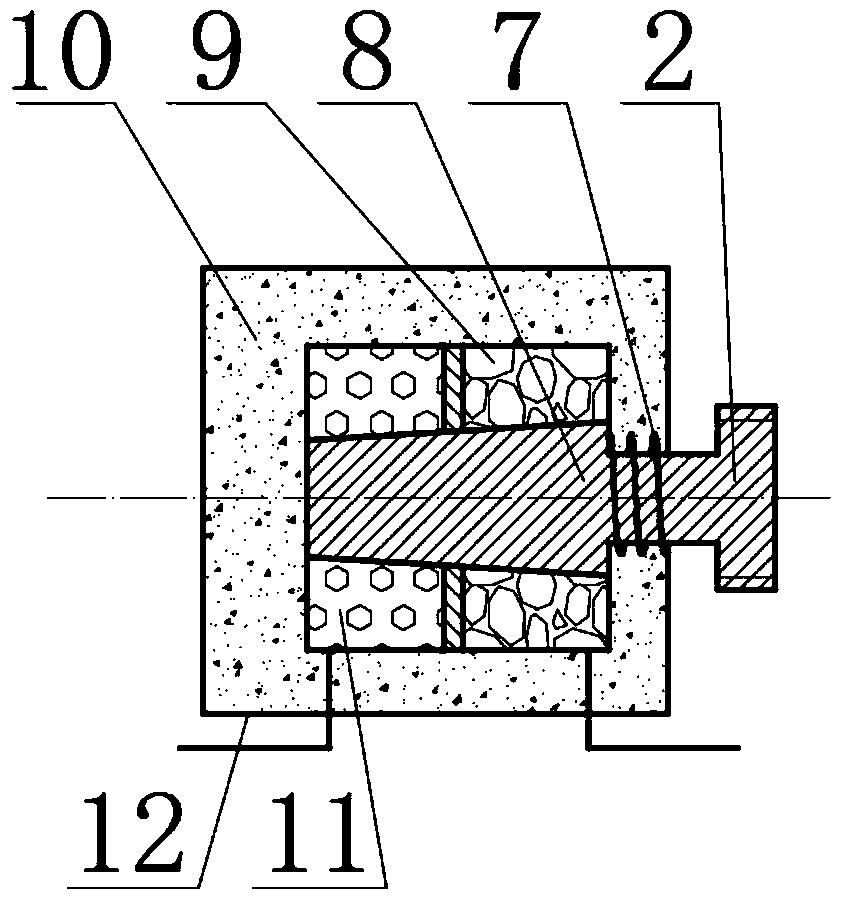

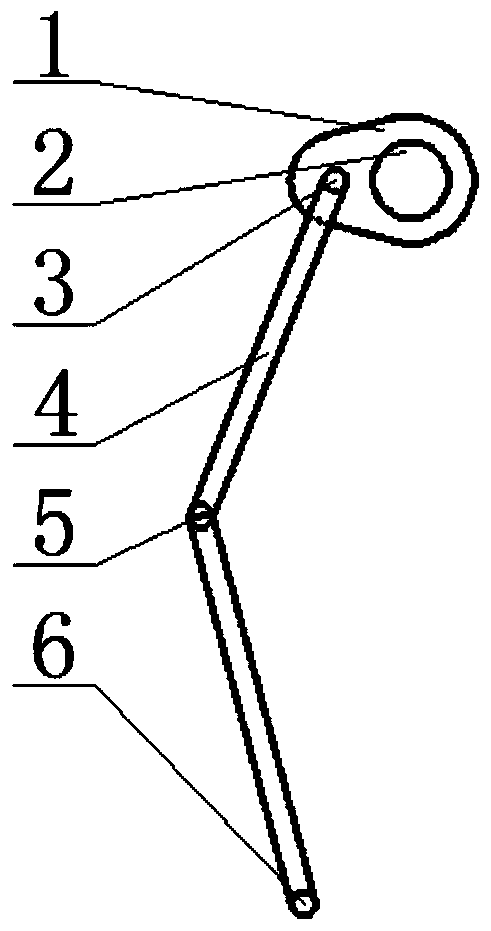

[0018] Such as figure 1 , figure 2 , image 3 A single-chamber microbial power generation device with a shaft hole and a thermophilic anaerobic shown,

[0019] A single-chamber microbial power generation device with thermophilic thermophilic anaerobic shaft holes, the power generation device is composed of three systems, namely a mechanical transmission system, a friction heating system and a microbial power generation system; wherein the mechanical transmission system consists of a cam structure 1, a transmission Structure 4, force shaft 6 and support shaft 5 integrated with flexible knee pad structure, wherein the cam structure 1 is also provided with a force shaft 3 connected to the transmission structure 4, and a gear pump driving structure solid with the gear pump driving hydraulic system. The driven gear 2 of the lock; the frictional heating system includes the driven gear 2, the cone-shaped friction column 8 made of insulating material with a bevel angle of 8°-10° dr...

Embodiment 2

[0026] The whole is consistent with Example 1, the difference is:

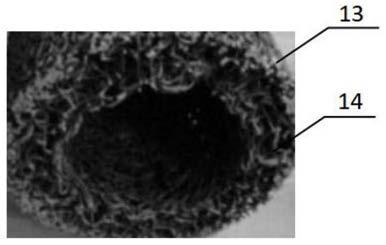

[0027] Wherein the manufacturing method of the anode wear-resistant disc composite structure 9 comprises the following steps:

[0028]① Raw material preparation: Prepare a 10mm thick disc-shaped 3D needle-punched carbon fiber preform 13, sufficient amount of thionyl chloride, sufficient amount of phenylenediamine; prepare 100g of epoxy resin and 20g of sub-medium temperature epoxy resin curing agent by weight , vulcanizing agent 1g, silane coupling agent 1.5g, graphite powder 8g, yeast extract: yeast extract agar compound nutrient base with a mass ratio of 1:1, moderate thermophilic acidophilic iron oxidizing bacteria agent;

Embodiment 3

[0030] The whole is consistent with Example 1, the difference is:

[0031] Wherein the manufacturing method of the anode wear-resistant disc composite structure 9 comprises the following steps:

[0032] ① Raw material preparation: Prepare a 4mm thick disc-shaped 3D needle-punched carbon fiber preform 13, sufficient amount of thionyl chloride, sufficient amount of phenylenediamine; prepare 120g of epoxy resin and 15g of sub-medium temperature epoxy resin curing agent by weight , vulcanizing agent 0.8g, silane coupling agent 1g, graphite powder 5g, yeast extract: yeast extract agar compound nutrient base with a mass ratio of 1:1, moderate thermophilic acidophilic iron oxidizing bacteria agent;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com