Fertilizer for improving broccoli yield and quality and preparation method thereof

A technology for broccoli and yield, applied in the direction of microorganism-based methods, biochemical equipment and methods, fertilizers made from biological waste, etc., can solve the problems of unsatisfactory nutritional quality and low yield of broccoli, and achieve full utilization , good slow release and adsorption, and the effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

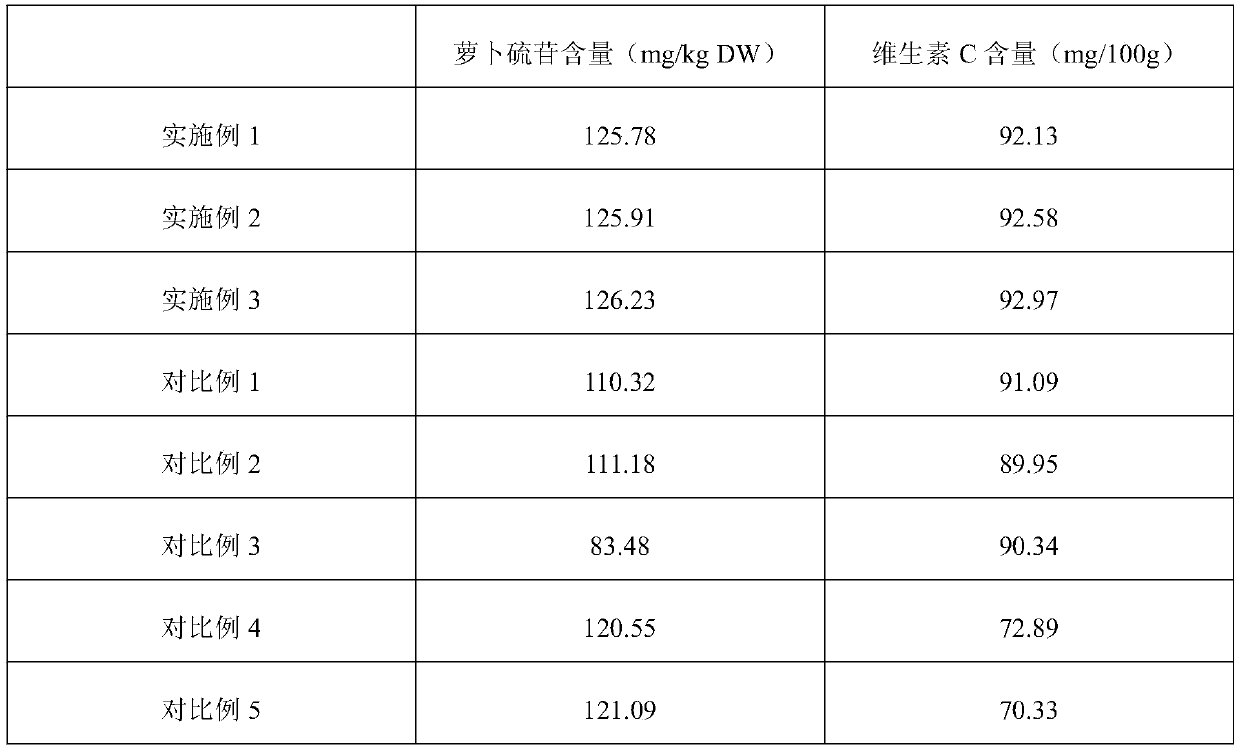

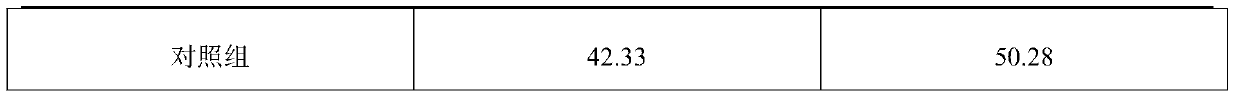

Examples

Embodiment 1

[0039] A kind of preparation method of the fertilizer that improves broccoli output and quality, by weight, concrete steps are as follows:

[0040] (1) Firstly, 10 parts of 100-mesh corn stalk powder are made into porous microspheres through hydrothermal reaction, and then the porous microspheres are mixed evenly with 6 parts of 40-mesh cottonseed hull powder to obtain mixed powder;

[0041] (2) Then 8 parts of polyglutamic acid are dissolved in 80 parts of water, poured into the mixed powder obtained in step (1), ultrasonically oscillated, sprayed and granulated to obtain granules;

[0042] (3) Add 3 parts of inorganic fertilizer components, 0.2 parts of mixed bacteria powder, and 0.8 parts of corn-enteromorpha mixed fermentation product into 40 parts of water, and ultrasonically oscillate evenly to obtain an aqueous solution, and finally pour the particles obtained in step (2) into In aqueous solution, dipping, and vacuum freeze-drying, a kind of fertilizer that improves the...

Embodiment 2

[0059] A kind of preparation method of the fertilizer that improves broccoli output and quality, by weight, concrete steps are as follows:

[0060] (1) Firstly, 10 parts of 200-mesh corn stalk powder are made into porous microspheres through hydrothermal reaction, and then the porous microspheres are mixed evenly with 5 parts of 50-mesh cottonseed hull powder to obtain mixed powder;

[0061] (2) Then 7 parts of polyglutamic acid were dissolved in 100 parts of water, poured into the mixed powder obtained in step (1), ultrasonically oscillated evenly, sprayed and granulated to obtain granules;

[0062] (3) Then add 2 parts of inorganic fertilizer components, 0.3 parts of mixed bacteria powder, and 0.5 parts of corn-enteromorpha mixed fermentation product into 50 parts of water, and ultrasonically oscillate evenly to obtain an aqueous solution, and finally pour the particles obtained in step (2) into In aqueous solution, dipping, and vacuum freeze-drying, a kind of fertilizer tha...

Embodiment 3

[0079] A kind of preparation method of the fertilizer that improves broccoli output and quality, by weight, concrete steps are as follows:

[0080] (1) Firstly, 10 parts of 200-mesh corn stalk powder are made into porous microspheres through hydrothermal reaction, and then the porous microspheres are mixed evenly with 5 parts of 40-mesh cottonseed hull powder to obtain mixed powder;

[0081] (2) Then 7.5 parts of polyglutamic acid are dissolved in 90 parts of water, poured into the mixed powder obtained in step (1), ultrasonically oscillated, sprayed and granulated to obtain granules;

[0082] (3) Add 2.5 parts of inorganic fertilizer components, 0.25 parts of mixed bacteria powder, and 0.6 parts of corn-enteromorpha mixed fermentation product to 45 parts of water, and ultrasonically oscillate evenly to obtain an aqueous solution, and finally pour the particles obtained in step (2) into In aqueous solution, dipping, and vacuum freeze-drying, a kind of fertilizer that improves ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com