Metal-supported hierarchical-pore ZSM-5 molecular sieve and preparation method and application thereof

A ZSM-5, multi-level pore technology, applied in the field of molecular sieves, can solve the problem of reducing the selectivity of target products, and achieve the effects of good application prospects, excellent stability, high activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

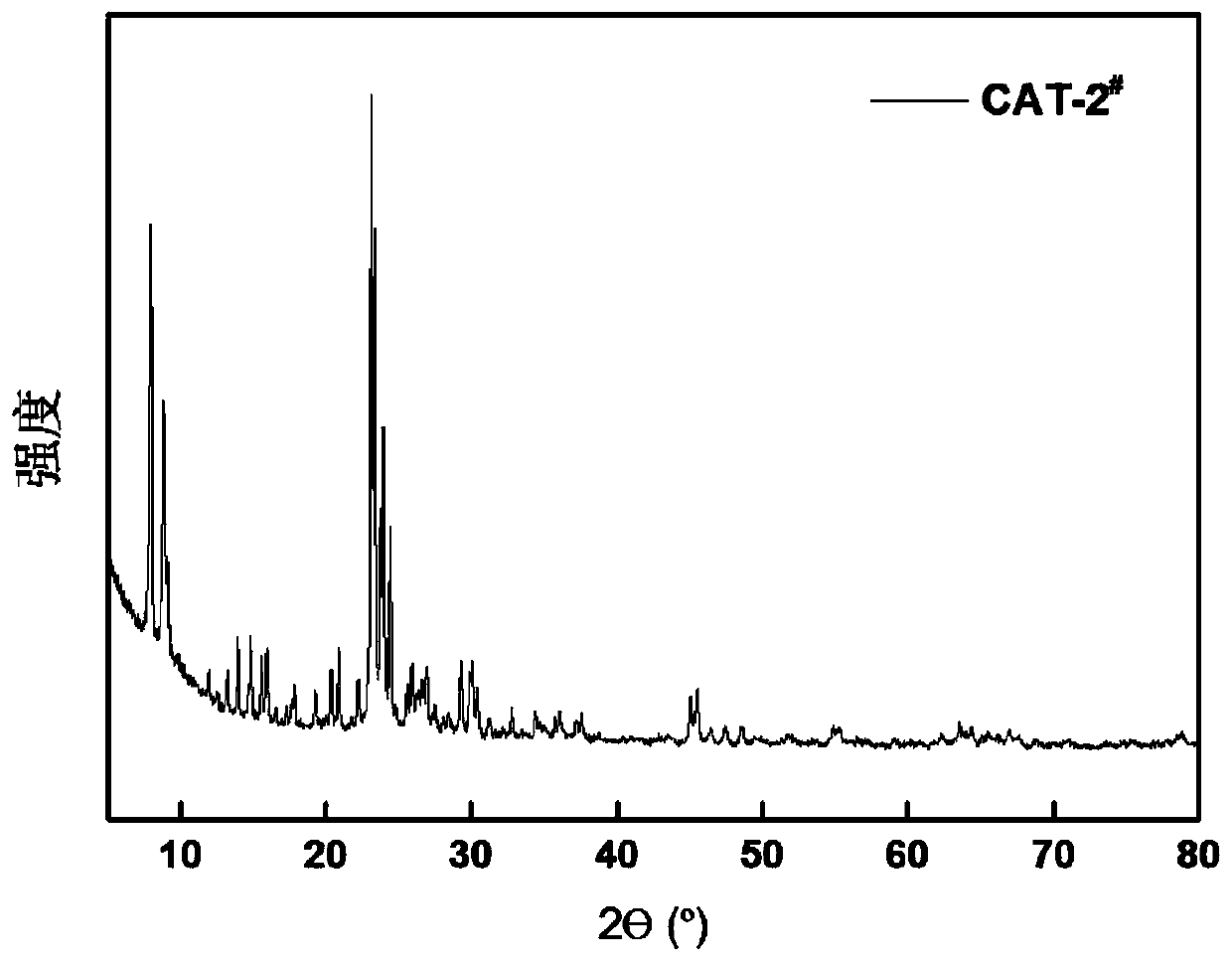

[0114] Example 1 Sample 1 # preparation

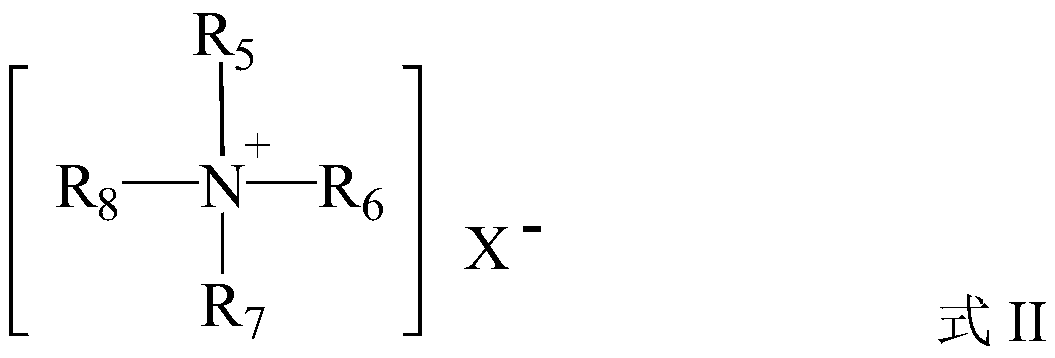

[0115] Mix 0.12g of aluminum isopropoxide, 12g of tetrapropylammonium hydroxide, 14mL of ethyl orthosilicate, 1.6mL of hexadecyltrimethoxysilane and 50mL of ethanol in a beaker, and stir at 25°C until a gel is formed; The gel was dried at 25°C for 48 h and placed in a 50 mL liner, and then the liner was transferred to a 250 mL stainless steel hydrothermal kettle with a polytetrafluoroethylene liner, and 60 mL of deionized water was added between the two liners to provide The water vapor atmosphere required for crystallization was crystallized at 180°C for 72 hours; after filtering, washing, drying at 110°C for 3 hours, and calcination at 550°C for 7 hours, the hierarchically porous ZSM-5 molecular sieve sample was obtained. for sample 1 # .

Embodiment 2

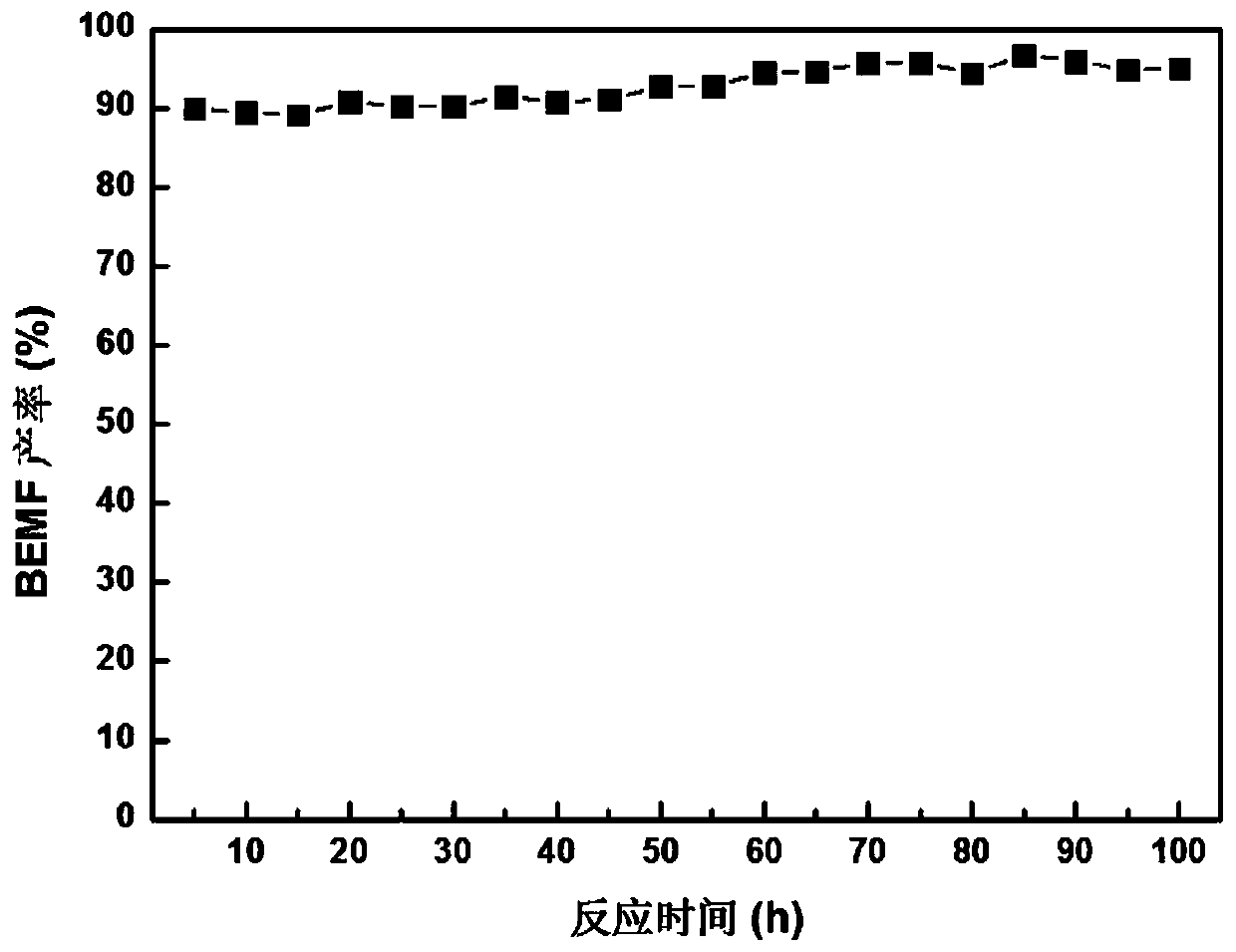

[0116] Example 2 Sample 2 # preparation

[0117] Mix 0.12g of aluminum isopropoxide, 12g of tetrapropylammonium hydroxide, 14mL of ethyl orthosilicate, 1.6mL of hexadecyltrimethoxysilane and 50mL of ethanol in a beaker, and stir at 25°C until a gel is formed; The gel was dried at 25°C for 48 h and placed in a 50 mL liner, and then the liner was transferred to a 250 mL stainless steel hydrothermal kettle with a polytetrafluoroethylene liner, and 60 mL of deionized water was added between the two liners to provide The water vapor atmosphere required for crystallization was crystallized at 180°C for 72 hours; after filtration, washing, drying at 110°C for 3 hours, and calcination at 550°C for 7 hours, the hierarchically porous ZSM-5 molecular sieve 1 was obtained. # sample. Take 0.1g stannous chloride dihydrate and add it to 4g deionized water, then add 4g hierarchical porous ZSM-5 molecular sieve 1 # Immerse for 48 hours, dry, and bake at 550°C for 7 hours to obtain the metal...

Embodiment 3

[0118] Example 3 Sample 3 # preparation of

[0119] Mix 0.10g of aluminum isopropoxide, 12g of tetrapropylammonium hydroxide, 14mL of ethyl orthosilicate, 1.6mL of hexadecyltrimethoxysilane and 50mL of ethanol in a beaker, and stir at 25°C until a gel is formed; The gel was dried at 25°C for 48 h and placed in a 50 mL liner, and then the liner was transferred to a 250 mL stainless steel hydrothermal kettle with a polytetrafluoroethylene liner, and 50 mL of deionized water was added between the two liners to provide The water vapor atmosphere required for crystallization was crystallized at 175°C for 72 hours; after filtration, washing, drying at 110°C for 2 hours, and calcination at 550°C for 6 hours, the hierarchically porous ZSM-5 molecular sieve sample was obtained. for sample 3 # .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesopore diameter | aaaaa | aaaaa |

| Mesopore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com