Cathode titanium roller surface grinding and polishing technology for raw foil manufacturing

A technology of surface grinding and titanium roller, applied in the field of surface grinding and polishing process of cathode titanium roller for green foil manufacturing, can solve the problems of oxide layer, influence of copper foil formation, and grinding marks, etc., and achieve low surface roughness, signal Delivers fast, highly malleable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

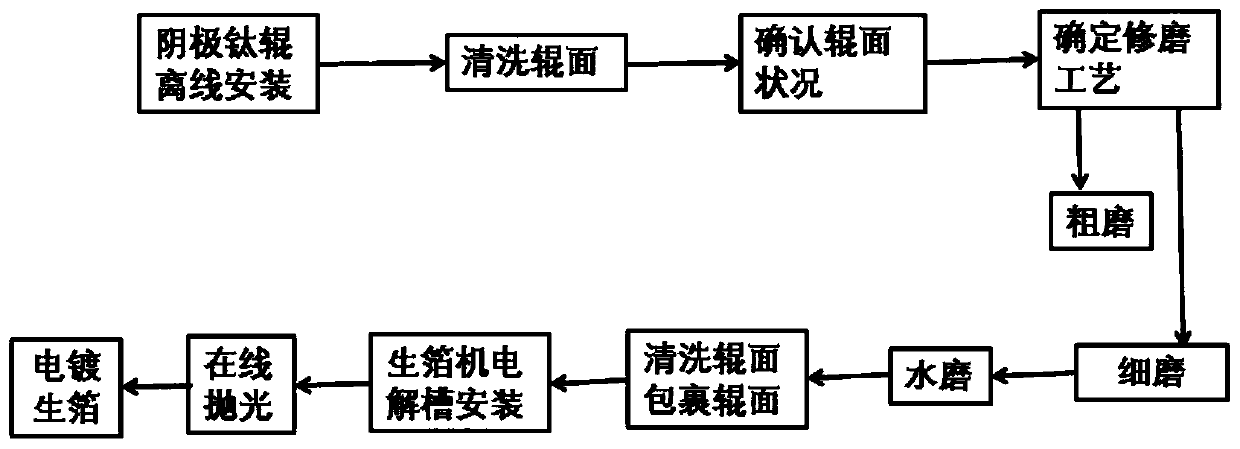

[0044] A surface grinding and polishing process of a cathode titanium roller for raw foil manufacturing, specifically comprising the following steps:

[0045] (1) The titanium roller hanging roller that needs to be ground offline goes to the roller room for offline installation and grinding. The installation steps are as follows:

[0046] a. Clean up the debris in the grinding tank to ensure that the grinding oil is clean;

[0047] b. Install titanium roller and titanium roller bearing cover: add butter to the bearing before installing the titanium roller, then cover the bearing, and then tighten the screws;

[0048] c. Install the rotating chain: Shake the handle of the travel screw of the main drive of the titanium roller counterclockwise, tighten the chain, and tighten the base fixing screw with a 24X27 wrench;

[0049] d. Carry out all-round inspection: confirm that the rotating chain of the titanium roller and the screws of each part are fastened, the grinding oil valve ...

Embodiment 2

[0066] Different from Example 1, the grinding oil is prepared according to Table 5:

[0067] table 5.

[0068] Water-soluble organic grinding oil 80L pure water 20L

[0069] If there is no obvious roller surface damage or electric damage to the roller, fine grinding and water grinding are carried out in sequence. The grinding process for titanium rollers is shown in Table 6-7:

[0070] Table 6. The second process: grinding oil fine grinding process

[0071]

[0072]

[0073] Table 7. The third process: water milling process

[0074]

[0075] All the other are identical with embodiment 1.

Embodiment 3

[0077] Different from Example 1, the grinding oil is prepared according to the formula of Table 8:

[0078] Table 8.

[0079] Water-soluble organic grinding oil 120L pure water 20L

[0080] If there is obvious damage on the roller surface, coarse grinding, fine grinding and water grinding are carried out in sequence. The grinding process for titanium rollers is shown in Table 9-11:

[0081] Table 9. The first process: coarse grinding process of grinding oil

[0082]

[0083]

[0084] Table 10. The second process: grinding oil fine grinding process

[0085]

[0086] Table 11. The third process: water milling process

[0087]

[0088] All the other are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com