Preparation method and product of carbon fiber composite material with designable characteristic structure

A technology of characteristic structure and composite materials, applied in the direction of additive processing, etc., can solve the problems of time-consuming and laborious sensing system, inability to realize online monitoring, weak resin interface bonding, etc., to improve the application range and service life, improve detection accuracy and Reliability, the effect of simplifying the measurement circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

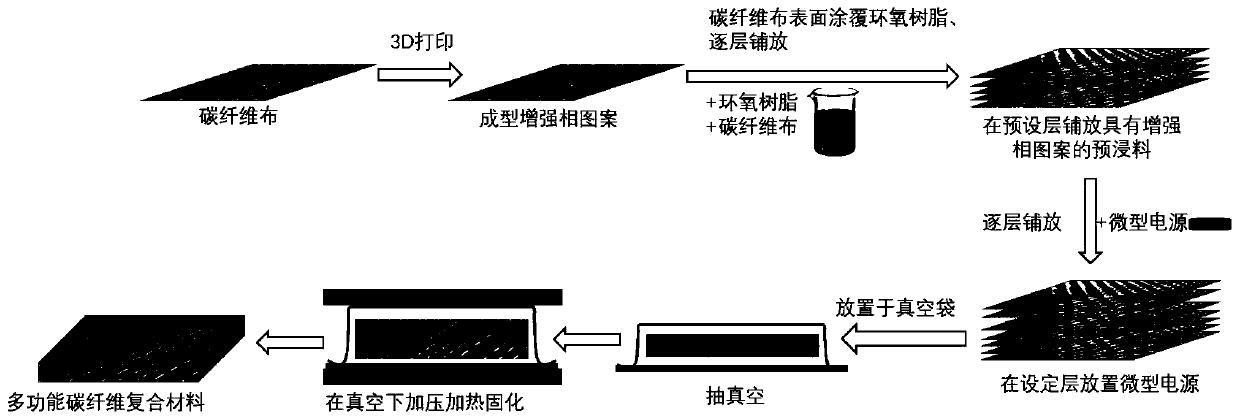

[0030] Such as figure 1 Shown, a kind of preparation method of the carbon fiber composite material of characteristic structure design, this method comprises the following steps:

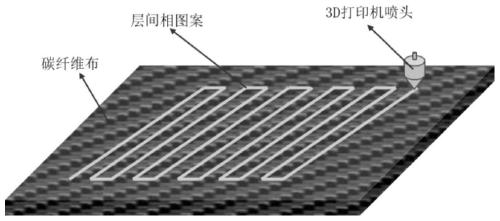

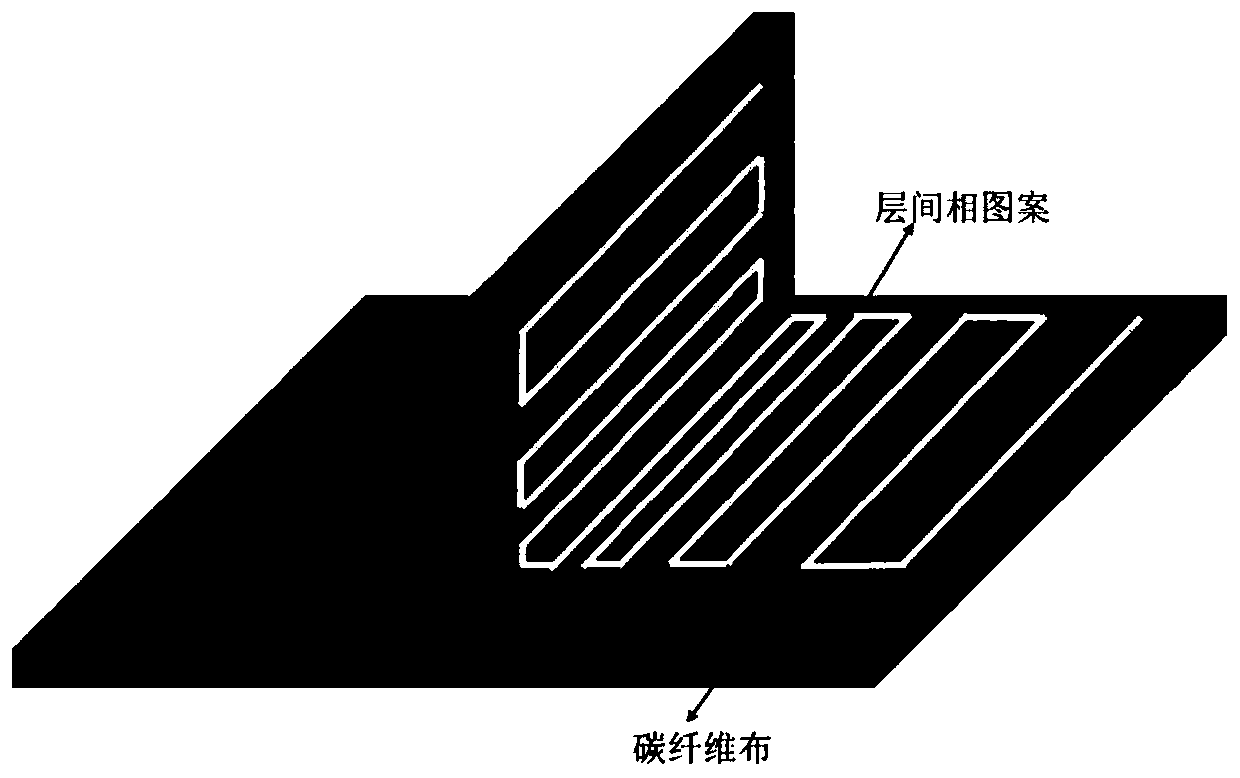

[0031] 1) Pre-design the interlayer reinforcement phase pattern, select the molding method to form the reinforcement phase on the surface of the carbon fiber, and realize the laying of the interlayer reinforcement material on the carbon fiber cloth.

[0032] The reinforcement phase material is selected as a polymer material with CNT added, for example, nylon (PA) with CNT added, which can improve the electrical conductivity while strengthening and toughening; the molding method can be selected as: 3D printing technology, electrospinning, fiber Technologies such as automatic wire laying, but not limited to the above methods.

[0033] 2) Lay the vacuum bag film on the workbench, fix and seal it with sealant; in order to make the resin completely infiltrate the fiber cloth, after laying a layer of isol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com