Method for producing environment-friendly polypropylene high-end fiber material

A fiber material, green and environmental protection technology, applied in the field of producing green and environmentally friendly polypropylene high-end fiber materials, can solve the problems of easy discoloration and peculiar smell of products, and achieve the effects of good fluidity, alleviation of raw material tension, and fast extrusion speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] A kind of method of producing green environmental protection polypropylene high-end fiber material, refer to figure 1 shown, including the following steps:

[0067] S1, prepare raw materials.

[0068] S2, establishing a production line.

[0069] S3, preparation of polypropylene base material.

[0070] S4, rheological control.

[0071] Among them, the prepared raw materials include raw materials such as propylene, nitrogen, hydrogen, catalysts, degradation agents, nucleating agents, additives, slip agents, etc.

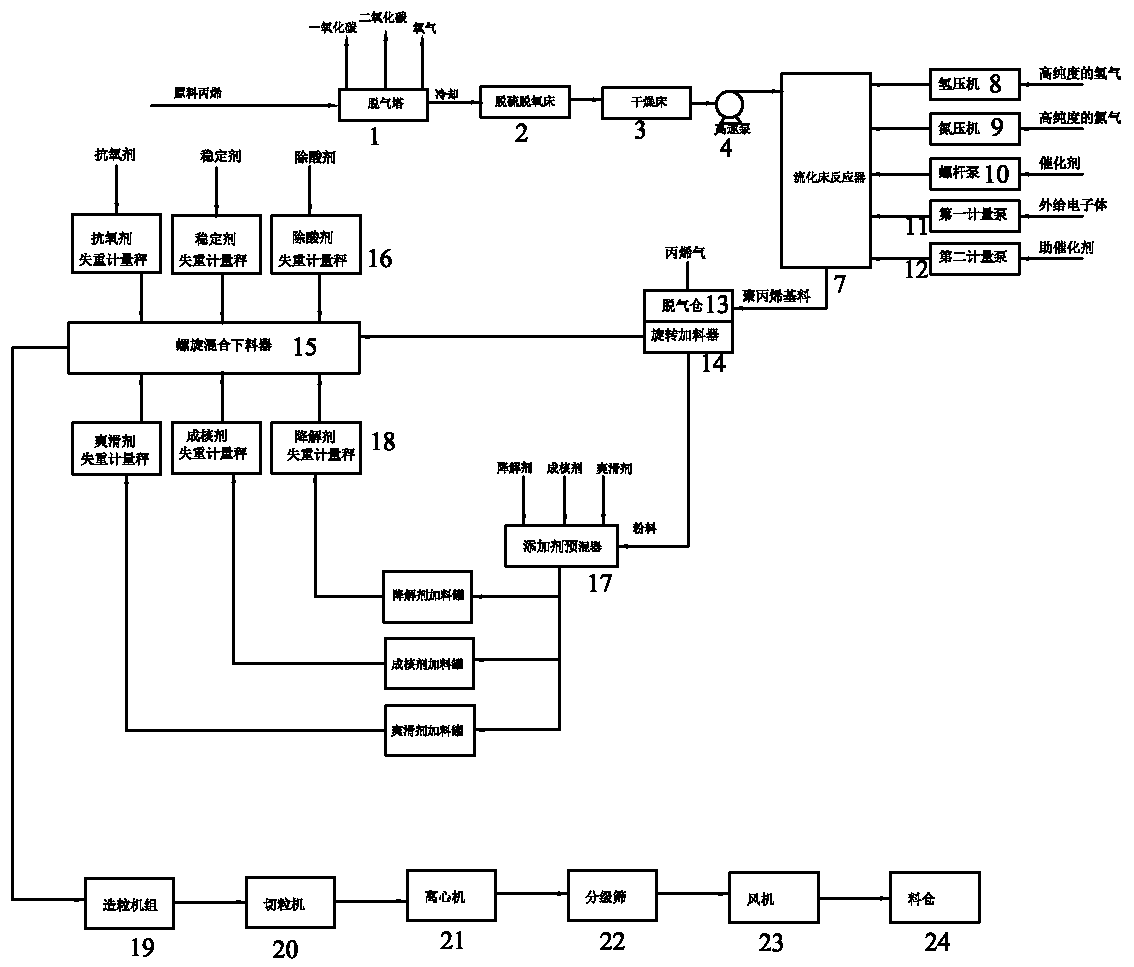

[0072] 1) Pass the raw material propylene with a purity greater than 99.65% through degassing tower 1, desulfurization and deoxidation bed 2, and drying bed 3 to remove impurities. It is required that the purity of propylene reaches more than 99.95% of the polymerization grade for the polymerization reaction, and the oxygen content, sulfur content, and carbon dioxide content are all less than 1.0ppm, the water content is less than 2 ppm, and the carbon monox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com